Fischer-Tropsch synthesis fixed bed reactor

A fixed bed reactor, Fischer-Tropsch synthesis technology, applied in chemical instruments and methods, preparation of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of complicated and time-consuming installation, damage to product selectivity, and uneven filling of tubes and tubes, Achieve the effect of reducing the radial and axial temperature difference, improving the heat extraction effect and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

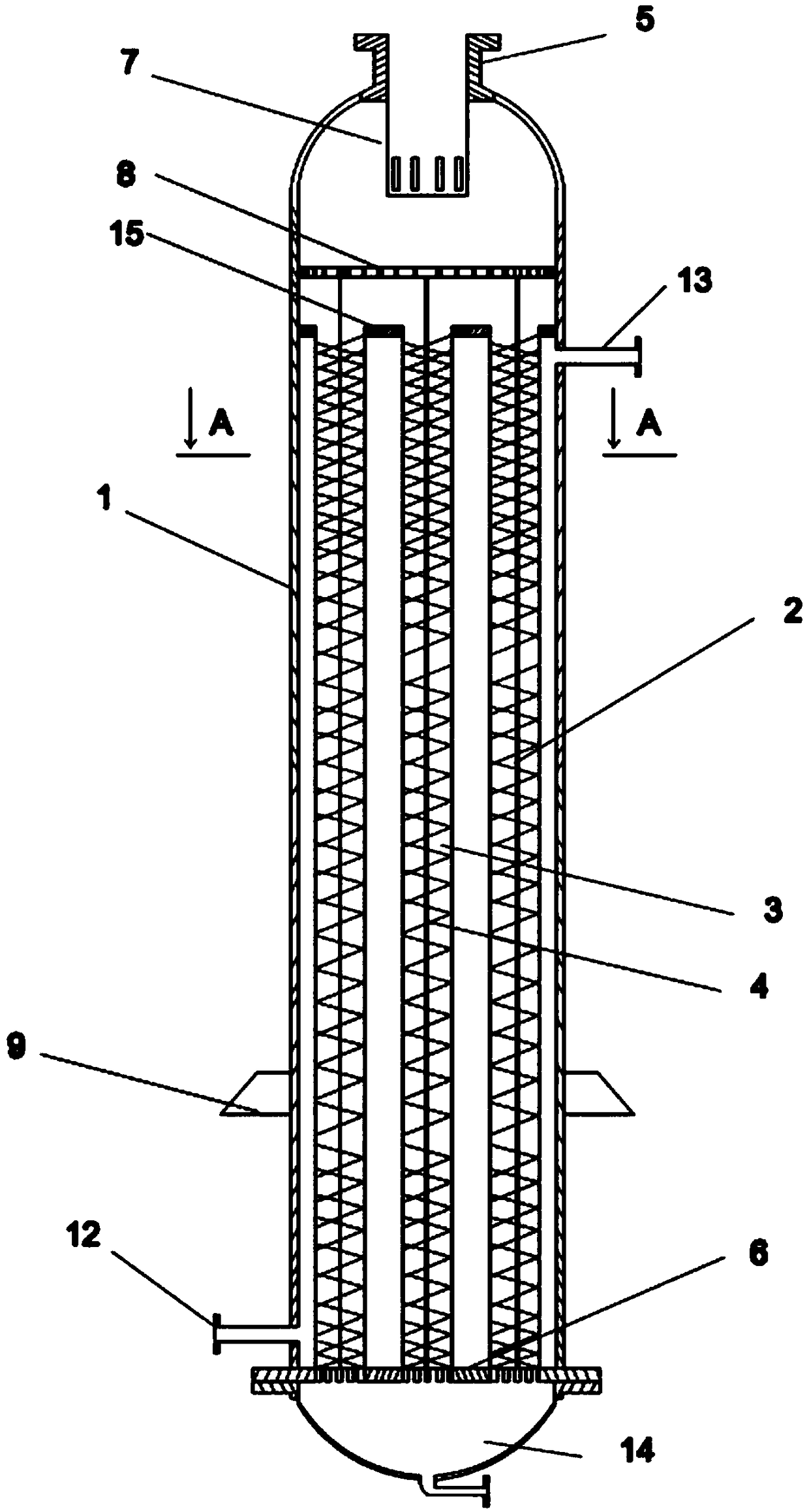

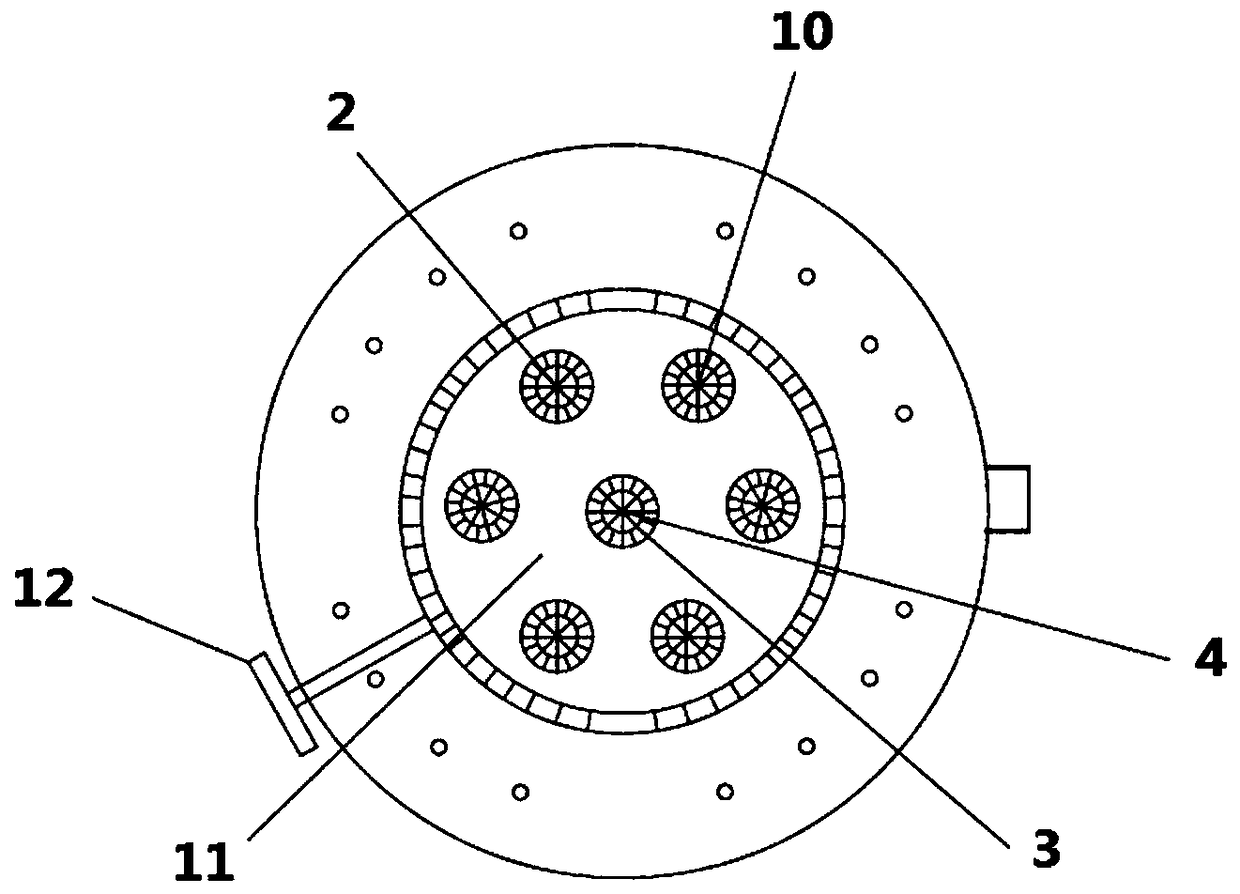

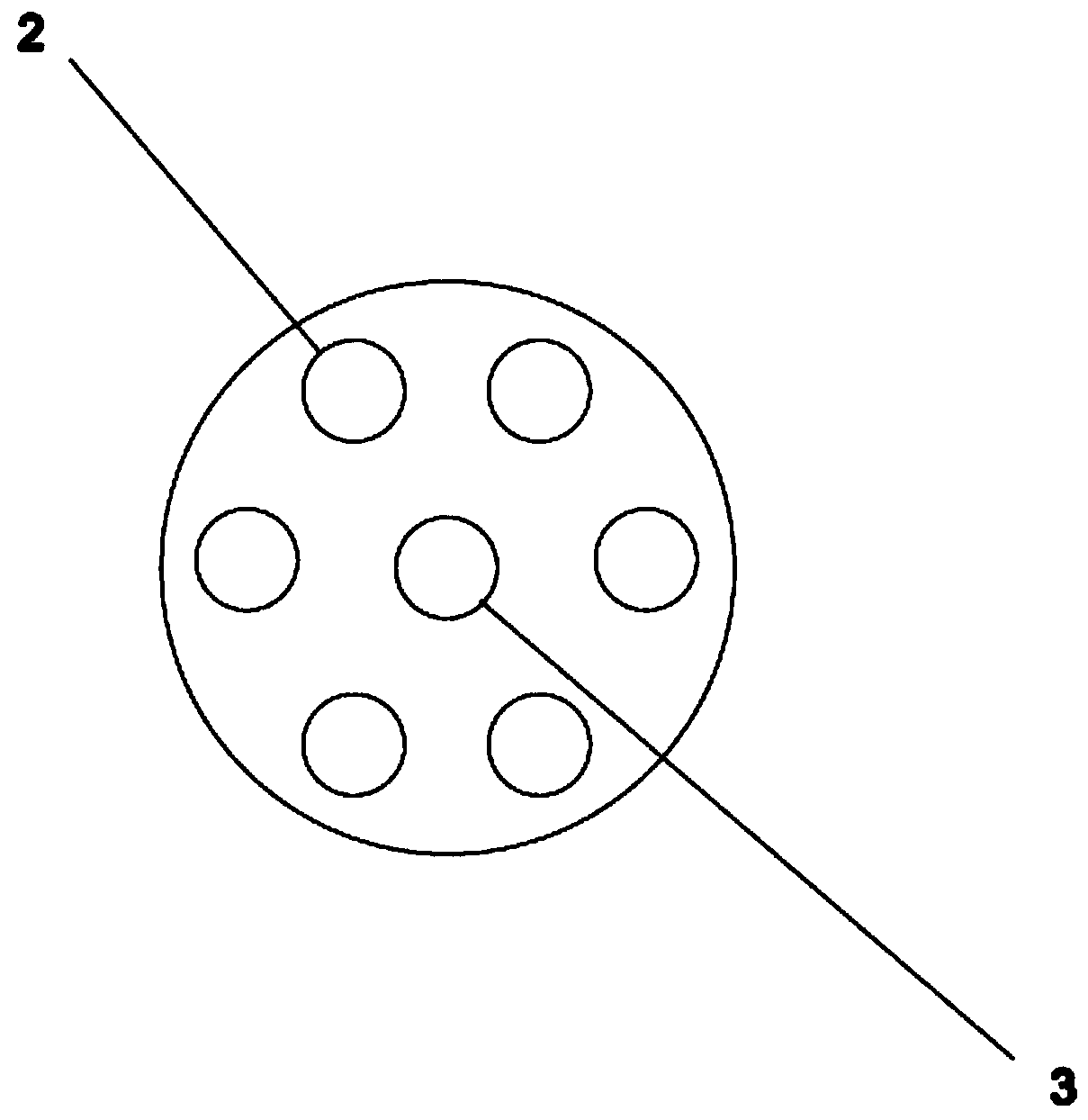

[0100] The radial cross-sectional view of the Fischer-Tropsch synthesis fixed bed reactor used in this embodiment along the line A-A is as follows figure 2 Shown. The diameter of the reactor tower body 1 is 0.42 m, and the total height of the reactor is 2.5 m. The reaction tubes 2 uniformly arranged around the central tube 3 and arranged in parallel to the central tube 3 in the axial direction have a tube length of 2.0m and a diameter of 60mm. The number of reaction tubes 2 is 6, and the arrangement is as follows Figure 8 (The reaction tubes 2 are arranged in a single row around the center tube 3); the center distance L between the reaction tube 2 adjacent to the center tube 3 and the center tube 3 is 4 times the inner diameter R of the reaction tube 2. The thermowell 4 located in the center tube 3 and the reaction tube 2 has a diameter of 1 / 4 inch and a length of 2.0 m, and a temperature measuring thermocouple is set every 0.45 m. The heat-conducting medium in the heat-condu...

Embodiment 2

[0114] The axial cross-sectional view of the Fischer-Tropsch synthesis fixed-bed reactor used in this embodiment is as follows figure 1 Shown. The diameter of the reactor tower body 1 is 0.50m, and the total height of the reactor is 2.5m. The reaction tubes 2 uniformly arranged around the central tube 3 and arranged in parallel to the central tube 3 in the axial direction have a tube length of 2.0m and a diameter of 40mm. The number of reaction tubes 2 is 18, and the arrangement is as follows Picture 9 (The number of reaction tubes 2 close to the central tube 3 is 6, and the number of reaction tubes 2 close to the wall of the reactor tower 1 is 12, the ratio of the two is 6:12); the reaction tubes adjacent to the central tube 3 The center distance L between 2 and the central tube 3 is 4 times the inner diameter R of the reaction tube 2. The thermowell 4 located in the central tube 3 has a diameter of 1 / 4 inch and a length of 2.0 m, and a thermocouple is set every 0.45 m. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com