Discharge method of waste lithium ion battery

A lithium-ion battery, waste technology, used in secondary battery charging/discharging, battery recycling, secondary battery repair/maintenance, etc., can solve problems such as being unsuitable for waste lithium-ion batteries, poor safety, and battery electrode corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

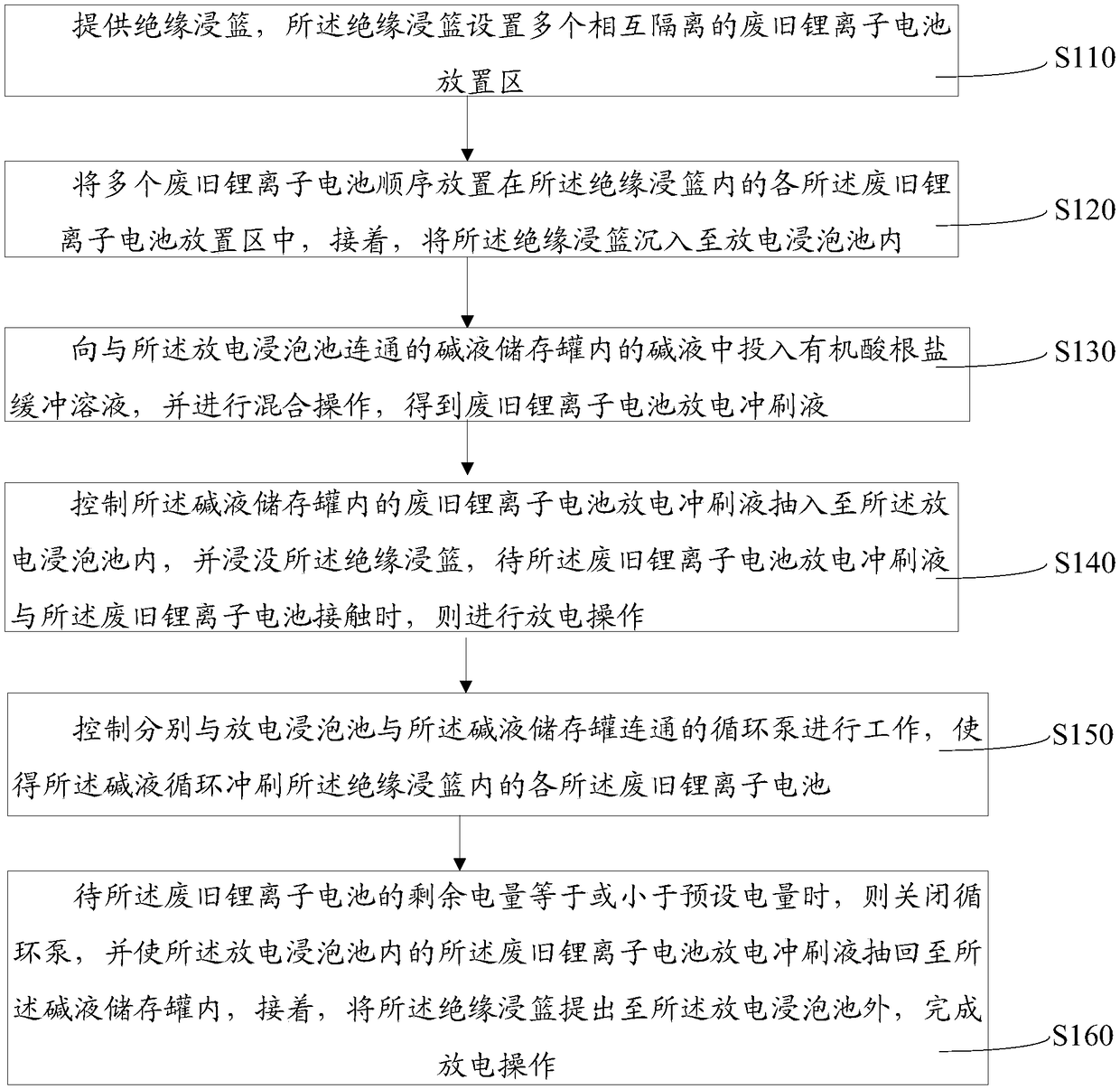

[0065] Provide an insulated immersion basket, which is provided with 100 separate storage areas for waste lithium-ion batteries;

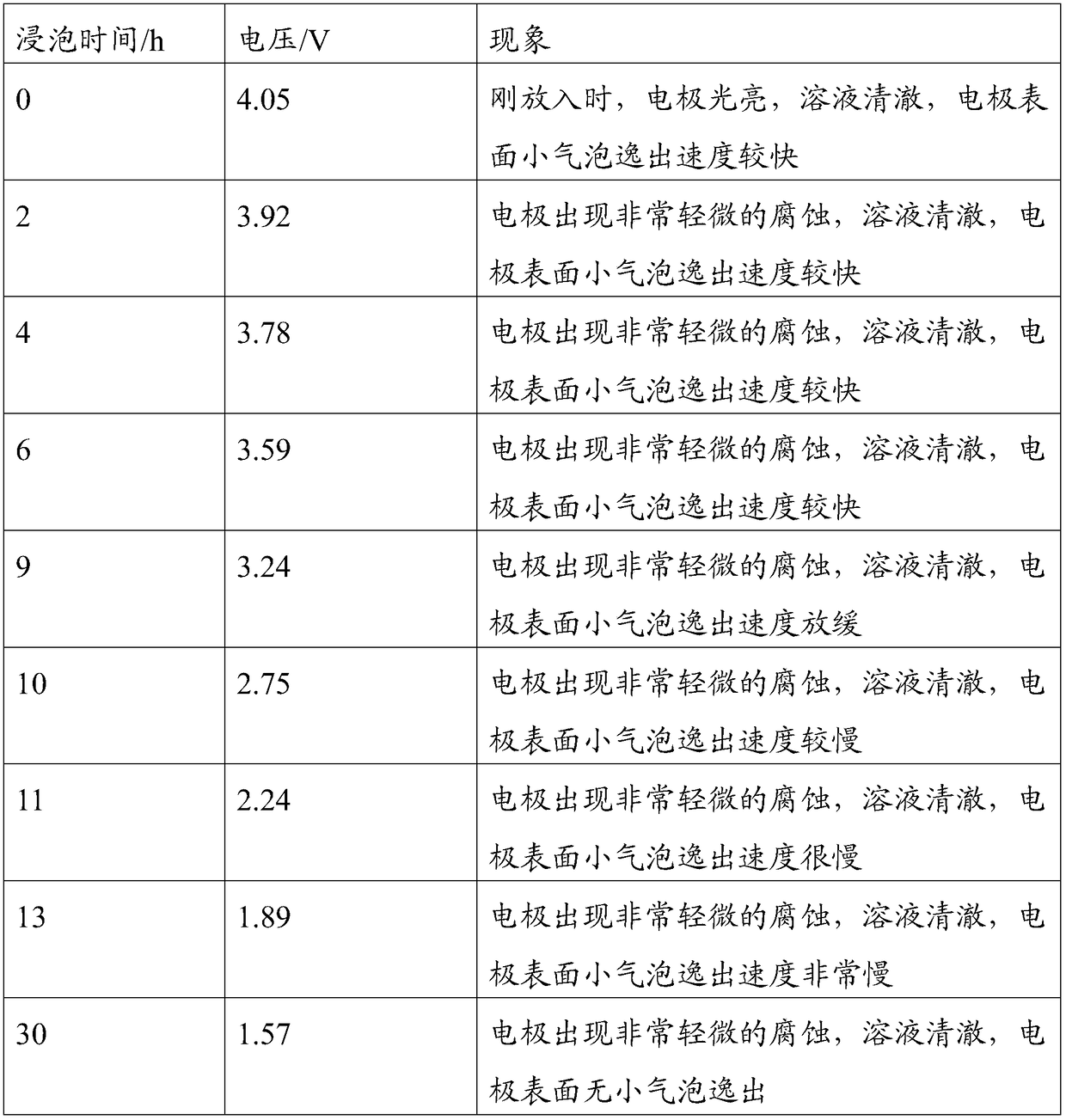

[0066] Use a 60V, 100A lithium battery charge-discharge tester to pre-discharge 100 used lithium iron phosphate batteries, and then place the pre-discharged 100 used lithium iron phosphate batteries in order in order to place the spent lithium ion batteries in the insulating immersion basket Then, sink the insulating immersion basket into the discharge immersion tank;

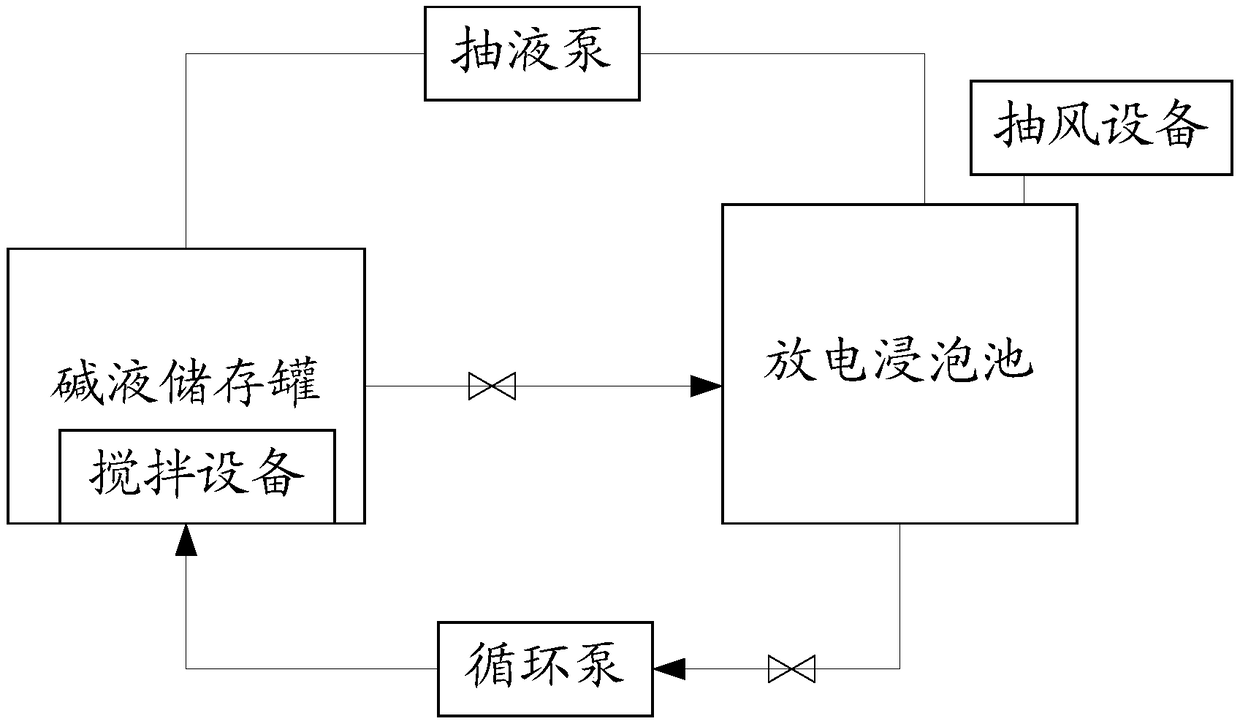

[0067] Put sodium citrate buffer solution into the sodium hydroxide solution in the lye storage tank connected with the discharge soaking tank, and perform mixing operation to obtain the discharge scouring liquid of the waste lithium ion battery;

[0068] Control the waste lithium-ion battery discharge scouring fluid in the lye storage tank and pump it into the discharge soaking tank and immerse the insulating immersion basket. When the waste lithium-ion battery discharge scouring fluid co...

Embodiment 2

[0072] Provide an insulated immersion basket, which is provided with 100 separate storage areas for waste lithium-ion batteries;

[0073] Use a 60V, 100A lithium battery charge-discharge tester to pre-discharge 100 used ternary lithium-ion batteries, and then place the pre-discharged 100 used ternary lithium-ion batteries in order in the insulated immersion basket. In the battery placement area, then, sink the insulating immersion basket into the discharge immersion tank;

[0074] Put sodium citrate buffer solution into the lithium hydroxide solution in the lye storage tank connected with the discharge soaking tank, and perform mixing operation to obtain the discharge flushing liquid of the waste lithium ion battery;

[0075] Control the waste lithium-ion battery discharge scouring fluid in the lye storage tank and pump it into the discharge soaking tank and immerse the insulating immersion basket. When the waste lithium-ion battery discharge scouring fluid comes into contact with th...

Embodiment 3

[0079] Provide an insulated immersion basket, which is provided with 100 separate storage areas for waste lithium-ion batteries;

[0080] Use a 60V, 100A lithium battery charge-discharge tester to pre-discharge 100 spent lithium manganese batteries, and then place the pre-discharged 100 spent lithium manganese batteries in order in the insulated immersion basket. Then, sink the insulating immersion basket into the discharge immersion tank;

[0081] Put sodium ascorbate buffer solution into the potassium hydroxide solution in the lye storage tank connected to the discharge soaking tank, and perform mixing operation to obtain the discharge flushing liquid of the waste lithium ion battery;

[0082] Control the waste lithium-ion battery discharge scouring fluid in the lye storage tank and pump it into the discharge soaking tank and immerse the insulating immersion basket. When the waste lithium-ion battery discharge scouring fluid comes into contact with the waste lithium-ion battery, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com