A method for manufacturing a high-frequency silicon capacitor

A technology of silicon capacitors and manufacturing methods, which is applied to electric solid devices, circuits, electrical components, etc., can solve the problems of low operating frequency of silicon capacitors, the inability to use advanced 3D packaging in capacitor packaging forms, and low operating frequency, and achieves the improvement of silicon capacitors. Intra-chip uniformity, good step coverage, and improved capacity accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0037] The embodiment of the present invention takes an N-type high-frequency silicon capacitor as an example, the first conductivity type is N-type, and the second conductivity type is P-type. A method for manufacturing a high-frequency silicon capacitor is characterized in that it includes the following step:

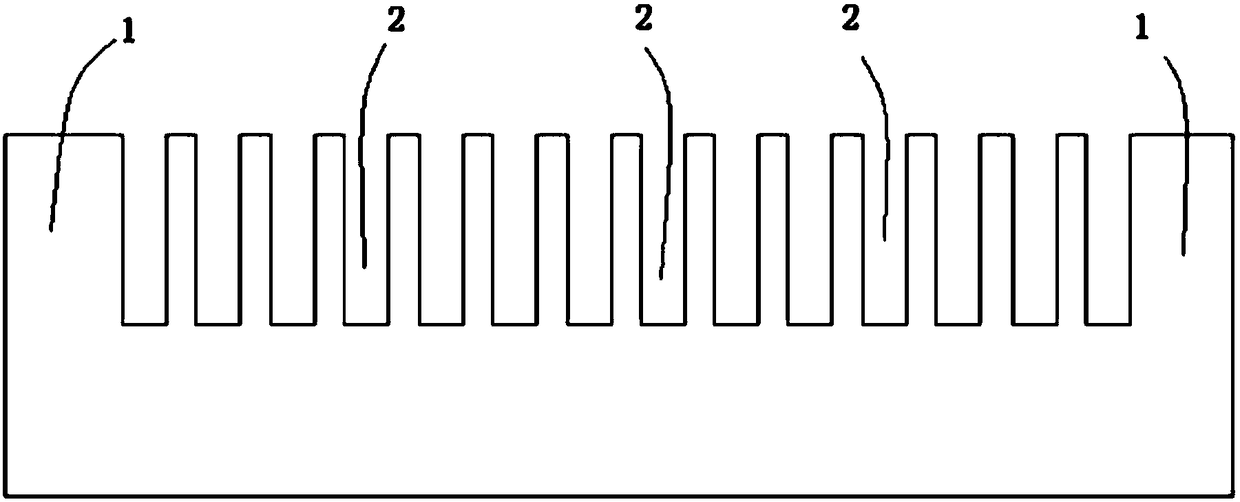

[0038] Such as figure 1 As shown, step 1. Provide a P-type substrate 1, etch several grooves 2 on the P-type substrate 1;

[0039] Specifically, before etching the trench 2, a layer of SiO is grown on the surface of the P-type substrate 1. 2 Masking layer 10, SiO 2 The thickness of masking layer 10 is about 1200nm, etching SiO 2 masking layer 10, resulting in SiO 2 masking window, the SiO 2 Under the cover of the masking window, etch the P-type substrate 1 to obtain several trenches 2 in the P-type substrate 1, the width of the trenches 2 is 1-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com