Physical squeezing method for preparing tea-oil tree seed oil

A hydraulic oil extraction and grapefruit oil technology, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of overcooling, affecting the quality of oil products, and the reduction of the nutritional value of grapefruit oil, etc., to achieve oil output High efficiency, improved crystallization effect, accelerated crystallization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for physically squeezing mountain grapefruit oil includes the processes of screening, drying, crushing, steaming and frying, and hydraulically squeezing mountain grapefruit seeds to obtain crude oil, and then filtering the crude oil to obtain refined oil.

[0041] First put the grapefruit seeds in the flotation solution, and set the grapefruit seeds and the flotation solution to be centrifuged together for 15~30min, then select the grapefruit seeds that settle in the lower part of the flotation solution to complete the screening; the flotation solution consists of 1 mass part ~10 parts of sodium oleate are dissolved in 50~100 parts of water by mass. The mass parts of sodium oleate can be any value from 1 to 10 parts, such as 1 part, 2 parts, 5 parts, 6 parts, 8 parts, 10 parts, etc., and the mass parts of water can be any value from 50 to 100 parts. Values, such as 50 parts, 60 parts, 80 parts, 85 parts, 90 parts, 100 parts, etc., and the ratio of sodium oleate to...

Embodiment 2

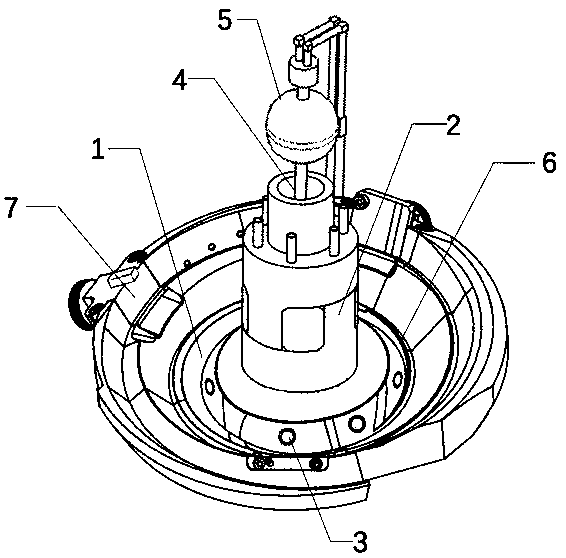

[0046] Such as figure 1 As shown, the winterizer includes a accommodating portion 1 with a plurality of annular grooves 6 on the outer wall and a heat exchange plate 7. The heat exchange plate 7 is made of semiconductor material, which is the same as in the prior art to realize heating / cooling exchange through semiconductor materials. The structure and principle of the hot plate are the same; the middle of the accommodating part 1 is provided with a closed and hollow channel column 2, and the hollow of the channel column 2 can be used to hold the separating liquid, and the bottom wall of the channel column 2 is provided with a number of outflow holes 3 , There can be a flap at the orifice of the outflow hole. The flap can only be opened to the outside when the internal force is applied to cause the liquid / gas inside the channel column 2 to flow out without causing the liquid in the receiving part 1 Flow into the channel column 2, the flap is the same as the prior art; above the...

Embodiment 3

[0048] The steps of winterization are as follows: place the crude oil in figure 1 In the winterization device shown, after the temperature is reduced to a certain temperature, the grapefruit oil is dewaxed, decolorized, and recrystallized.

[0049] Step one (sub-division):

[0050] Methylpentane, sodium hydroxymethylcellulose and sodium hydroxide are added in a small amount of water to dissolve the sodium hydroxide in a molar ratio of 1:0.4:0.1, and then a mixed solution (separated liquid) is made.

[0051] Place the grapefruit oil to be processed in the accommodating part 1, turn on the air pump to continuously discharge the gas in the gas chamber 5 from the trachea 4, and then flow it into the channel column 2 according to the volume ratio of fractionated liquid: grapefruit oil 0.2:1 Add the fraction liquid, adjust the gas pump to keep the gas flow rate at 1-20 mL / min, make the fraction liquid enter the containing part 1 through the outflow hole 3 with the gas and react with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com