One-step rapid controllable preparation method of full-emission fluorescence carbon quantum dots

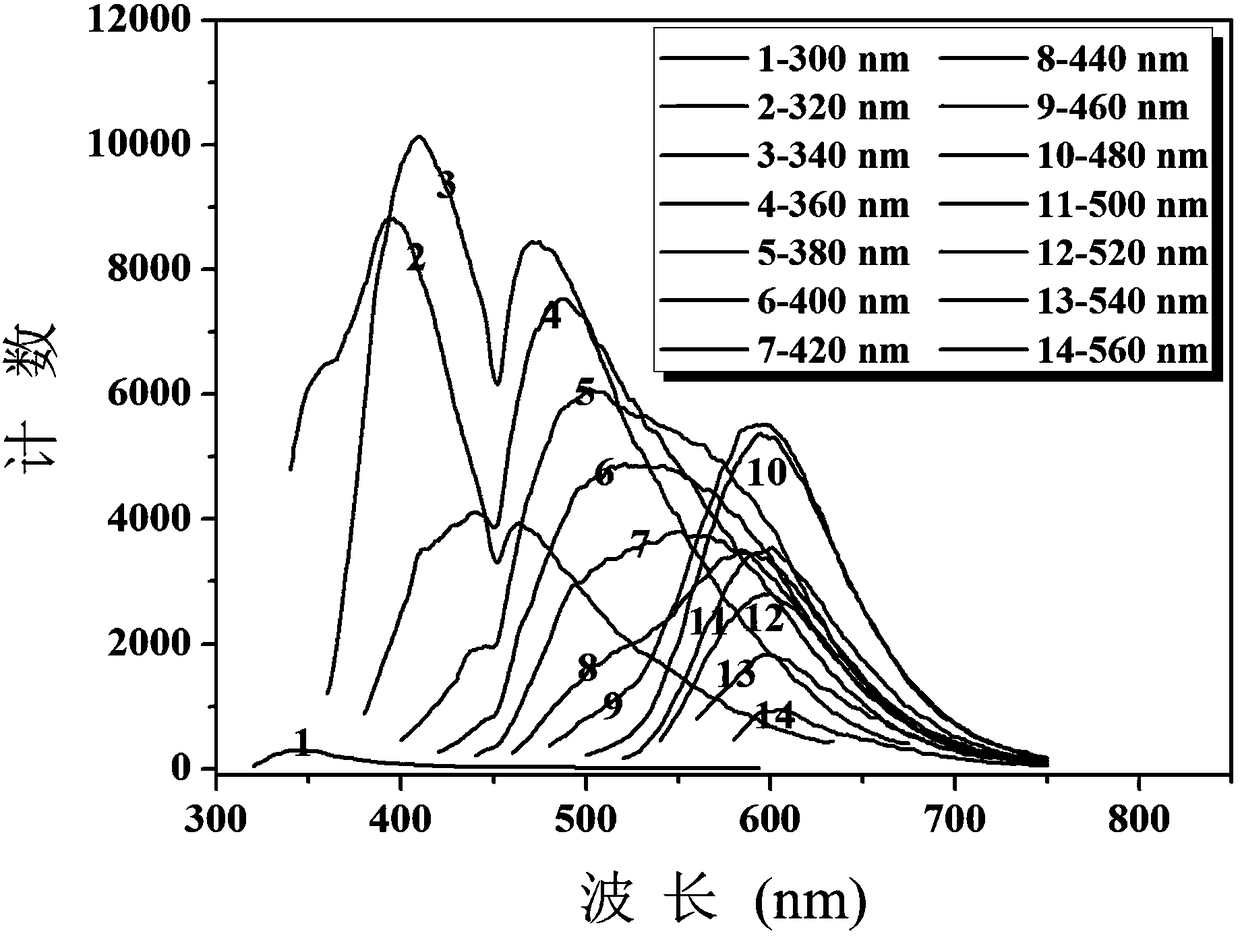

A carbon quantum dot, full-emission technology, applied in the field of one-step rapid and controllable preparation of full-emission fluorescent carbon quantum dots, can solve the problems of low fluorescence quantum efficiency, single emission wavelength, uncontrollable preparation, etc., and achieves high fluorescence quantum efficiency. Solve the effect of single emission wavelength, fast response and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: A one-step rapid and controllable preparation method of all-emission fluorescent carbon quantum dots, the steps are as follows:

[0019] (1) Weigh 0.05 g of p-phenylenediamine and 0.05 g of p-aminobenzoic acid, add them into 10 mL of absolute ethanol, and sonicate at 20°C and 40 kHz for 10 min to obtain a uniform and colorless mixed solution;

[0020] (2) Transfer the mixed solution to a 50 mL polytetrafluoroethylene autoclave with a temperature lower than 230 °C, and place it in an oven at 150 °C for 11 h to obtain a black solution. The rotary evaporation condition is: temperature 35 °C , vacuum degree 0.085 MPa, rotation speed 100rpm; rotary evaporation to remove ethanol, dissolve it in secondary water, centrifuge to remove insoluble matter, use 500 Da dialysis bag for dialysis treatment for three days to remove non-luminescent substances, and obtain pure fluorescent carbon quantum dots aqueous solution;

[0021] (3) The above-mentioned fluorescent carb...

Embodiment 2

[0022] Embodiment 2: A one-step rapid and controllable preparation method of all-emission fluorescent carbon quantum dots, the steps are as follows:

[0023] (1) Weigh 0.01 g of m-phenylenediamine and 0.09 g of m-aminobenzoic acid, add them into 8 mL of absolute ethanol, and sonicate at 20°C and 40 kHz for 10 min to obtain a uniform and colorless mixed solution;

[0024] (2) Transfer the mixed solution to a 50 mL polytetrafluoroethylene autoclave with a temperature lower than 230 °C, and place it in an oven at 160 °C for 10 h to obtain a black solution. The controlled rotary evaporation condition is: temperature 35 ℃, vacuum degree 0.085 MPa, rotating speed 100 rpm, remove ethanol by rotary evaporation, dissolve it in secondary water, centrifuge to remove insoluble matter, use 500-1000 Da dialysis bag for three days to remove non-luminescent substances, and obtain pure Fluorescent carbon quantum dot aqueous solution;

[0025] (3) The above-mentioned fluorescent carbon quantum...

Embodiment 3

[0026] Embodiment 3: A one-step rapid and controllable preparation method of all-emission fluorescent carbon quantum dots, the steps are as follows:

[0027] (1) Weigh 0.04 g of o-phenylenediamine and 0.16 g of anthranilic acid respectively, add them into 20 mL of absolute ethanol, and ultrasonically dissolve to obtain a uniform and colorless mixed solution;

[0028] (2) Transfer the mixed solution to a 100 mL polytetrafluoroethylene autoclave with a temperature lower than 230 °C, and place it in an oven at 170 °C for 11 h to obtain a black solution. The controlled rotary evaporation condition is: temperature 35 ℃, vacuum degree 0.085 MPa, rotation speed 100 rpm, rotary evaporation to remove ethanol, dissolve it in secondary water, centrifuge to remove insoluble matter, and use 2000 Da dialysis bag for three days to remove non-luminescent substances, and obtain pure fluorescent carbon Quantum dot aqueous solution;

[0029] (3) After freeze-drying the above-mentioned fluoresce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com