Modified plastic odor removal master batch and preparation method thereof

A technology for odor removal and odor removal agent, applied in the field of modified plastic odor removal masterbatch and its preparation, which can solve the problems of weak interaction between air stripping agent and porous polymer, harsh storage and transportation conditions, and inability to obtain use effects. , to avoid the effect of product performance or appearance, to meet the long-term storage, and to reduce the content of VOC harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] A preparation method for removing the odor of modified plastics masterbatch, comprising the following steps:

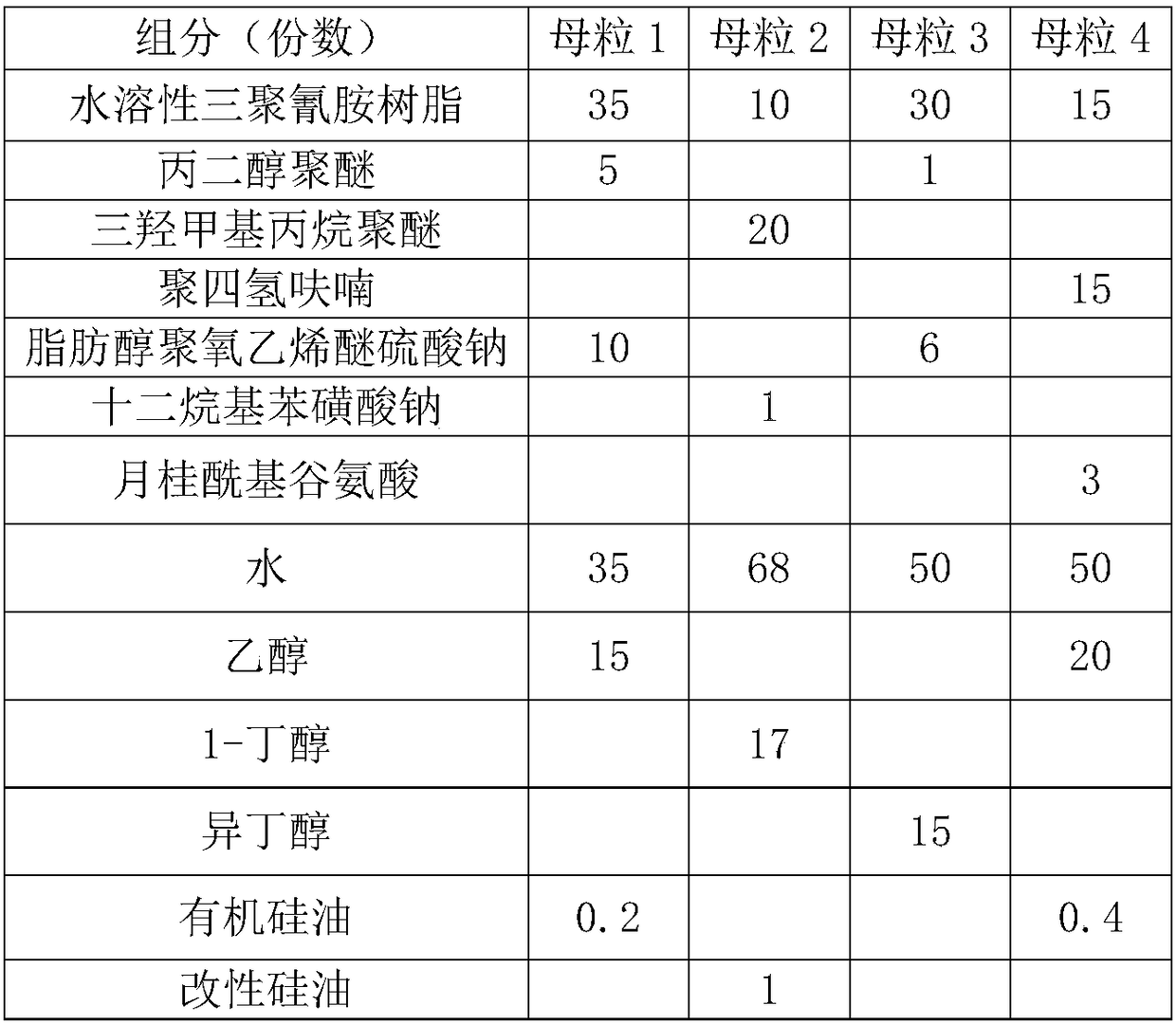

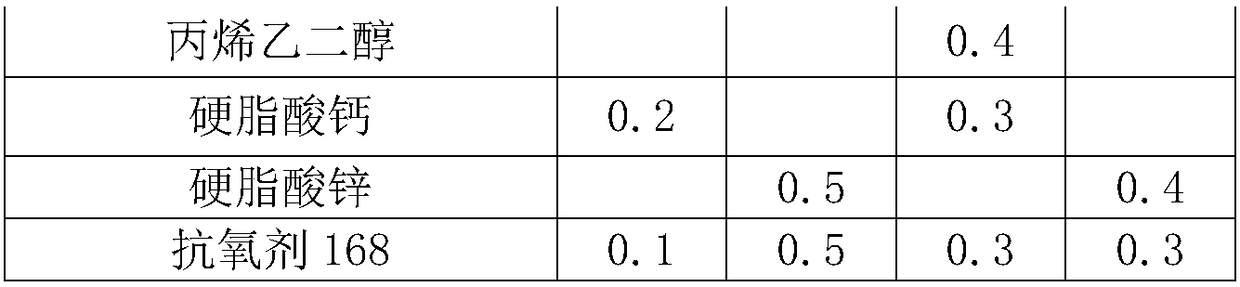

[0034] Step 1: Prepare raw materials: 10-35 parts of melamine resin, 1-20 parts of polyether polyol, 1-10 parts of interface treatment agent, 50-85 parts of odor remover, 0.5-2.0 parts of auxiliary agent;

[0035] Step 2: Fully mix melamine resin, polyether polyol, interface modifier, and additives to form a mixture, and then pass air into the mixture while continuously stirring rapidly to obtain a density of 1-20kg / m 3 foam carrier, preferably with a density of 2kg / m 3 , and crush it into 5-100 mesh particles, the preferred particle size is 10 mesh;

[0036] Step 3: Mix the granules in step 2 with the odor remover in a kettle-type container, fully absorb them, and prepare the odor remover masterbatch.

[0037] The melamine resin is water-soluble melamine resin.

[0038] The polyether polyols are oligomers containing ether bonds in the main chain and more th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com