High-strength admixture for assembly-type prefabricated concrete

A technology for prefabricated components and concrete, applied in the field of building materials, can solve the problems of extensive management, high energy consumption, unfavorable sustainable development of the prefabricated industry, etc., to achieve the effect of ensuring durability, improving early strength, and reducing the risk of shrinkage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

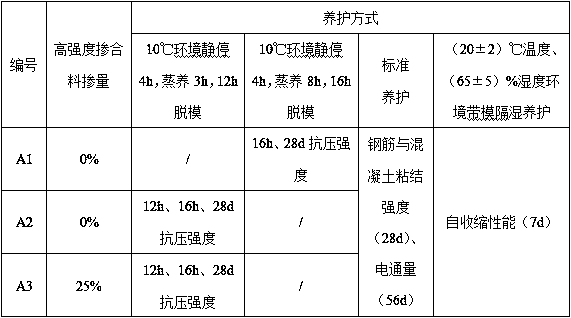

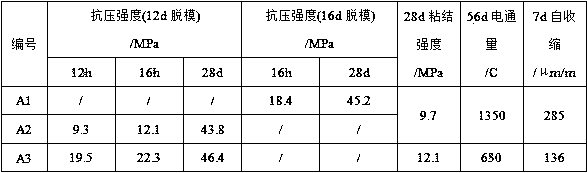

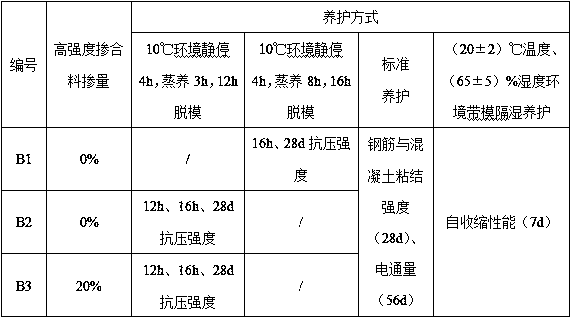

Image

Examples

Embodiment 1

[0031] A high-strength admixture for prefabricated concrete, consisting of the following components by weight percentage: 45% fine silica fume, 8% coke oven desulfurization by-product, 25% industrial desulfurization by-product gypsum, finely ground and oxidized Calcium powder 8%, finely ground magnesium oxide powder 6%, water-soluble siliceous active material 5.2%, cesium chloride 0.8%, triisopropanolamine 2%.

Embodiment 2

[0033] A high-strength admixture for prefabricated concrete, consisting of the following components by weight percentage: 30% fine silica fume, 14% coke oven desulfurization by-product, 36% industrial desulfurization by-product gypsum, finely ground and oxidized Calcium powder 10%, finely ground magnesium oxide powder 3%, water-soluble siliceous active material 3%, cesium chloride 1%, triisopropanolamine 3%.

Embodiment 3

[0035]A high-strength admixture for prefabricated concrete, consisting of the following components by weight percentage: 37% fine silica fume, 6% coke oven desulfurization by-product, 40% industrial desulfurization by-product gypsum, finely ground and oxidized Calcium powder 6%, finely ground magnesium oxide powder 7%, water-soluble siliceous active material 2%, cesium chloride 1%, triisopropanolamine 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com