Glass toughening liquid and glass toughening treatment method

A glass tempering and treatment method technology, applied in the field of glass tempering, can solve the problems of affecting the tensile strength of glass, unstable performance, glass microcracks, etc., and achieve the effect of improving glass strengthening effect, good heat resistance, and improving surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

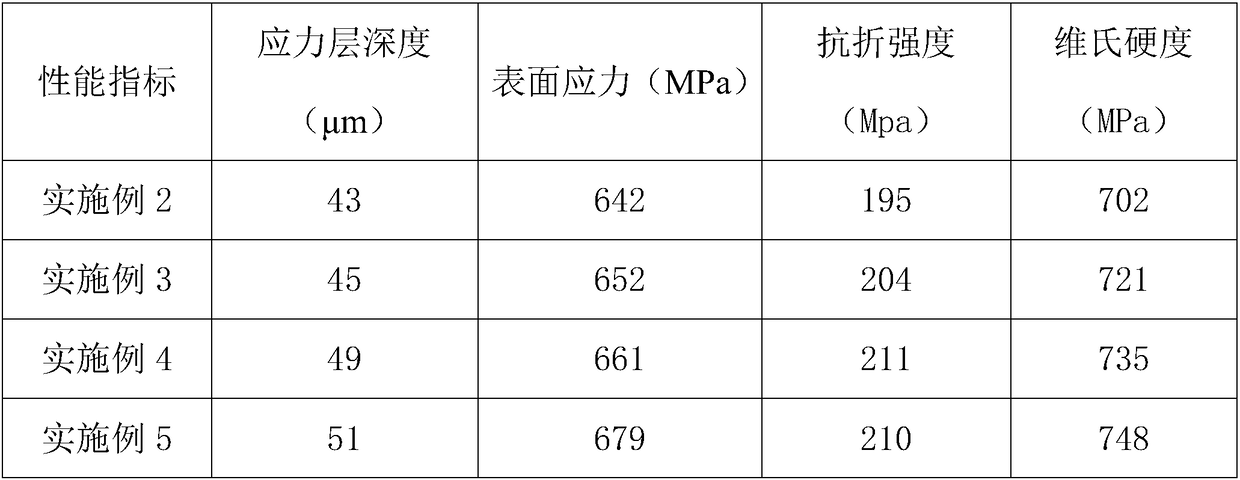

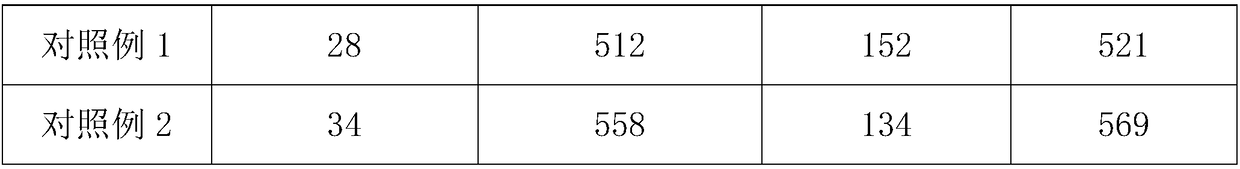

Examples

Embodiment 1

[0021] A method for tempering glass, comprising the steps of:

[0022] S1, preheating the glass at 630°C;

[0023] S2. Soak the preheated glass obtained in step S1 in the glass stiffening solution, the strengthening temperature is 380°C, and heat preservation reaction;

[0024] S3, performing annealing treatment on the tempered glass obtained in step S2, and air cooling to obtain tempered glass;

[0025] Among them, the glass tempering liquid is composed of 65 parts of potassium nitrate, 15 parts of diethanolamine borate, 5 parts of N-methyldiethanolamine, 8 parts of cerous nitrate, and 3 parts of magnesium oxide.

Embodiment 2

[0027] A method for tempering glass, comprising the steps of:

[0028] S1. Preheating the glass at 680°C;

[0029] S2. Soak the preheated glass obtained in step S1 in the glass stiffening solution, the strengthening temperature is 420°C, and the heat preservation reaction is 2 hours;

[0030] S3, performing annealing treatment on the tempered glass obtained in step S2 at 200° C., and the annealing time is 60 minutes and air cooling to obtain tempered glass;

[0031] Among them, the glass tempering liquid is composed of 80 parts of potassium nitrate, 5 parts of diethanolamine borate, 8 parts of N-methyldiethanolamine, 2 parts of cerous nitrate, and 5 parts of magnesium oxide.

Embodiment 3

[0033] A method for tempering glass, comprising the steps of:

[0034] S1, preheating the glass at 650°C;

[0035] S2. Soak the preheated glass obtained in step S1 in the glass stiffening solution, the strengthening temperature is 400°C, and the heat preservation reaction is 5 hours;

[0036] S3, performing annealing treatment on the strengthened glass obtained in step S2 at 290° C., and the annealing time is 180 minutes in air cooling to obtain tempered glass;

[0037] Among them, the glass tempering liquid is composed of potassium nitrate, diethanolamine borate, N-methyldiethanolamine, cerous nitrate, magnesium oxide, Al 2 o 3 and Sb 2 o 3 Composition, the weight ratio of potassium nitrate, diethanolamine borate, N-methyldiethanolamine, cerous nitrate, magnesium oxide is 70:13:6:6:4, potassium nitrate, diethanolamine borate, N-methyldiethanolamine The weight percentage of the total amount of base diethanolamine, cerous nitrate, and magnesium oxide in glass tempering liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com