A kind of petroleum liquid product-based graphene quantum dot and its preparation method and application

A technology of graphene quantum dots and liquid products, applied in the field of nanomaterials, can solve the problems of low yield and high preparation cost of graphene quantum dots, and achieve the effects of excellent performance, reduction of cumbersome and redundant steps, and reduction of processing steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

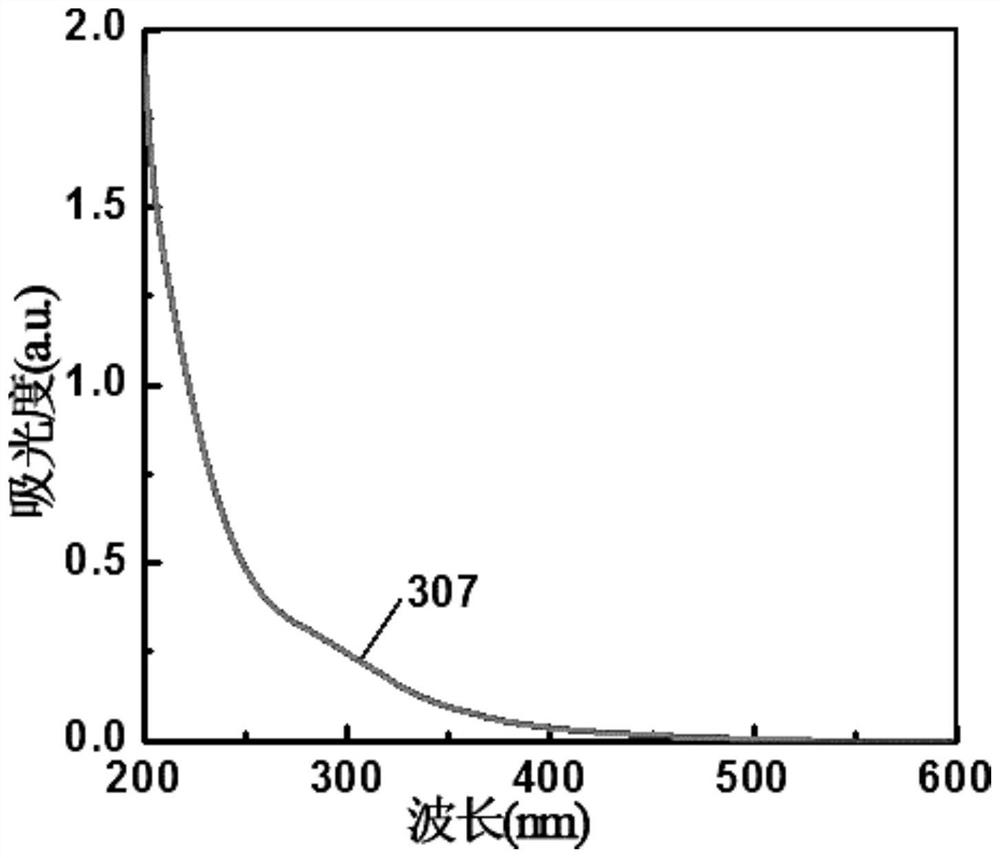

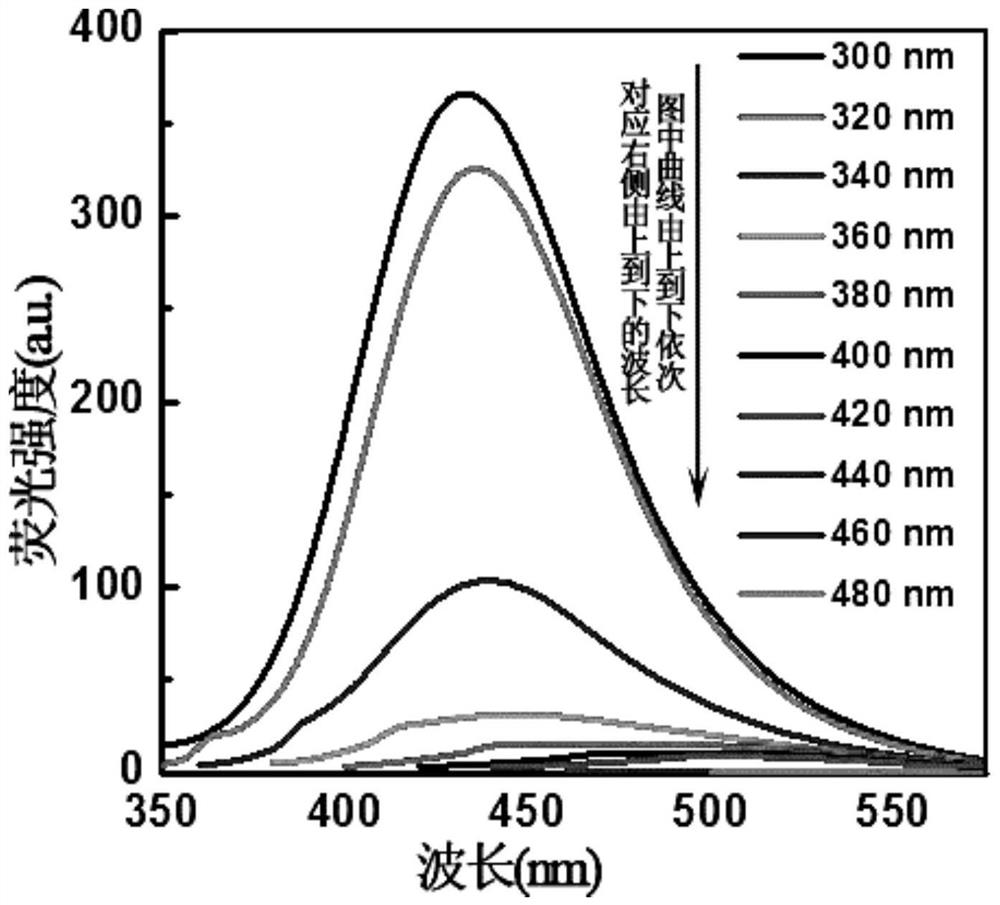

[0055] The present embodiment provides a preparation method of diesel-based graphene quantum dots and catalytically cracked gasoline-based graphene quantum dots, comprising the following steps:

[0056] Step 1: Measure 3mL of concentrated sulfuric acid and 1mL of concentrated nitric acid at room temperature and place them in a 10mL glass test tube added to the rotor, cool to room temperature, and slowly add 1mL (about 0.7-0.8g) of light diesel oil or FCC gasoline to 3mL of concentrated sulfuric acid. mixed with 1 mL of concentrated nitric acid, and then put a 10 mL glass test tube into a 400W ultrasonic cleaner for 2 hours to obtain a diesel-based dispersion or a catalytically cracked gasoline-based dispersion;

[0057] In step 2, the above-mentioned dispersion is oxidized in an oil bath at 120° C. for 24 hours, cooled to room temperature, and adjusted to neutrality with a sodium hydroxide solution to obtain a crude product of graphene quantum dots;

[0058] Step 3, the crude ...

Embodiment 2

[0065] The present embodiment provides a preparation method of diesel-based graphene quantum dots and catalytically cracked gasoline-based graphene quantum dots, comprising the following steps:

[0066] In step 1, 1.5mL of concentrated sulfuric acid and 0.5mL of concentrated nitric acid were placed in a 5mL microreactor with a magnetic stirrer and mixed, cooled to room temperature, and 0.5mL of diesel or catalytically cracked gasoline was added respectively, and then the microreactor was put into 400W Ultrasonic in the ultrasonic cleaner for 2h to obtain diesel-based dispersion or catalytically cracked gasoline-based dispersion;

[0067] Step 2, the above dispersion is stirred and oxidized in a microreactor at 120 ° C for 24 h, cooled to room temperature, and adjusted to neutrality with sodium hydroxide;

[0068] Step 3, adding 100mg of sodium borohydride (under ice bath conditions) to react for 4h to obtain diesel-based graphene quantum dots crude product or catalytic crackin...

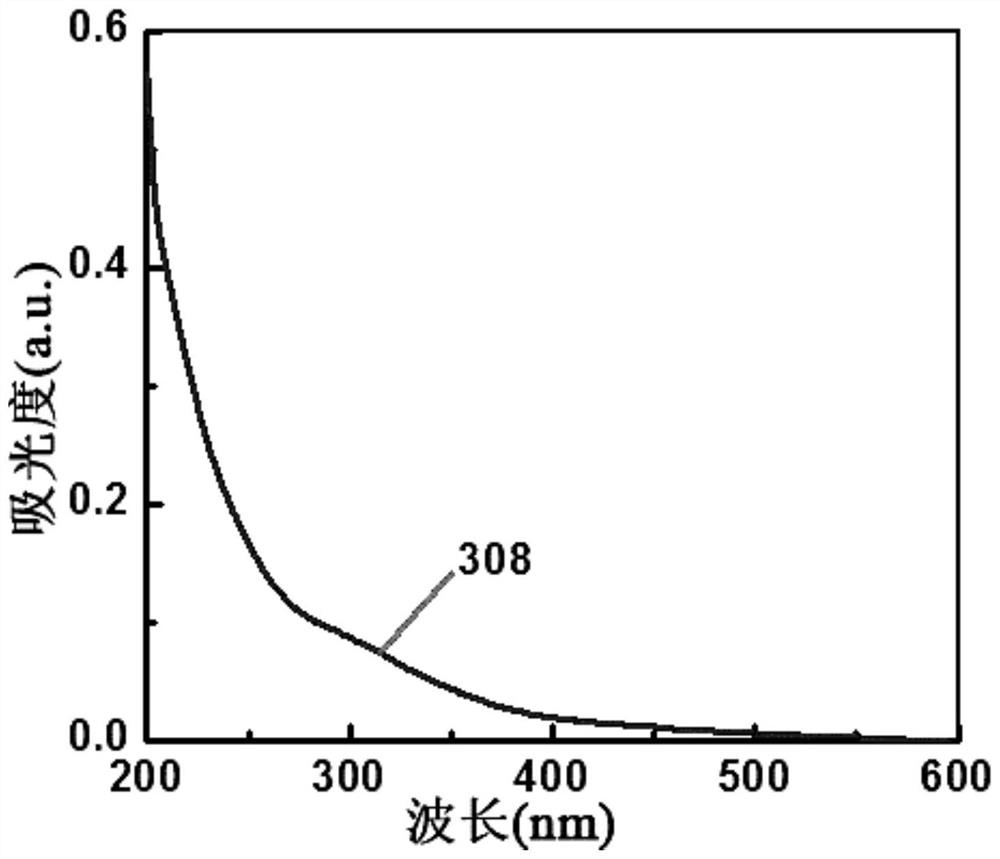

Embodiment 3

[0071] The operating conditions and operating steps were the same as in Example 2, except that the dialysis time was extended to 120h, and the dialysis water was changed every 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com