Preparation method and application of copper-doped graphite phase carbon nitride composite material

A graphite phase carbon nitride, composite material technology, applied in chemical instruments and methods, chemical/physical processes, oxidized water/sewage treatment, etc., can solve the problems of low degradation performance of organic dyes, and achieve poor degradation efficiency and cost. Low cost, widely available raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

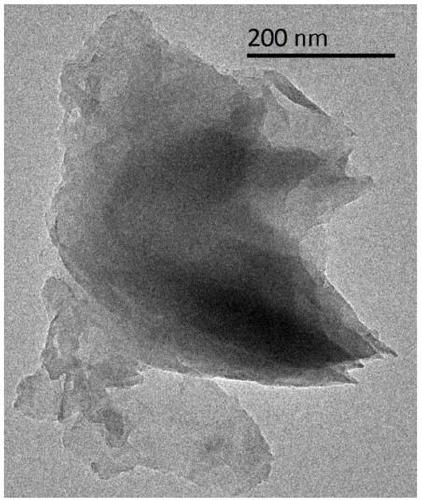

Image

Examples

Embodiment 1

[0042] At room temperature, pour 7g of copper chloride dihydrate into 300mL of 37% concentrated hydrochloric acid, seal and stir for 5-10min to dissolve. Slowly pour 10 g of melamine into the above solution, at this time a large amount of yellow solids are produced, place it in a constant temperature magnetic stirrer and stir for 1-3 hours. The yellow precursor was obtained by filtration, filled into an ark, put into a tube furnace and raised to 500°C at a rate of 10°C / min in an air atmosphere, kept at a constant temperature for 2 hours, and then naturally cooled to room temperature.

Embodiment 2

[0044] At room temperature, pour 7g of copper chloride dihydrate into 300mL of 37% concentrated hydrochloric acid, seal and stir for 5-10min to dissolve. Slowly pour 10 g of melamine into the above solution, at this time a large amount of yellow solids are produced, place it in a constant temperature magnetic stirrer and stir for 1-3 hours. The yellow precursor was obtained by filtration, filled into an ark, put into a tube furnace, raised to 550°C at a rate of 10°C / min in an air atmosphere, kept at a constant temperature for 2 hours, and then naturally cooled to room temperature.

Embodiment 3

[0046] At room temperature, pour 7g of copper chloride dihydrate into 300mL of 37% concentrated hydrochloric acid, seal and stir for 5-10min to dissolve. Slowly pour 10 g of melamine into the above solution, at this time a large amount of yellow solids are produced, place it in a constant temperature magnetic stirrer and stir for 1-3 hours. The yellow precursor was obtained by filtration, filled into an ark, put into a tube furnace, and raised to 580°C at a rate of 10°C / min in an air atmosphere, and kept at a constant temperature for 2 hours, then naturally cooled to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com