A kind of production method of salt-free soy sauce

A production method and technology of soy sauce, applied in the field of salt-free brewing and fermentation microorganisms, can solve the problems of high salt content, unfavorable wide application of soybean fermented food, and restriction of attention and correct understanding of the health function of soybean fermented food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

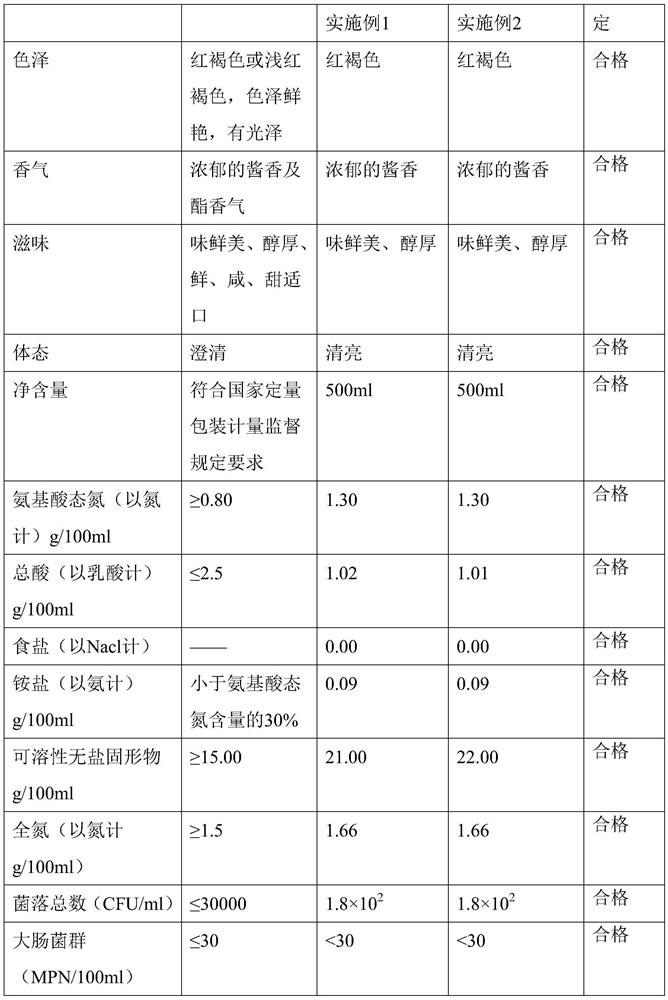

Examples

Embodiment 1

[0043] The present embodiment provides a kind of production method of salt-free soy sauce, comprises the following steps:

[0044] Step 1, koji making: From January to March of the lunar calendar, mix 5 parts by weight of natural Chinese herbal medicine powder with 14 parts by weight of dry malt powder, add water accounting for 55% of the total weight and mix evenly, then add 72 parts by weight Part steamed fried soybeans, 5 parts by weight of coarse wheat bran and stir to obtain the pre-inoculation material, then add 5% seed koji accounting for its total weight in the pre-inoculation material under the condition of 34 ° C and stir evenly to complete the inoculation , finally under the condition that the temperature is 21~23°C and the humidity is 80%, it is cultivated to obtain koji material. During this period, the temperature of the koji material before cultivation is 28~30°C, and the temperature of the koji material during the cultivation period is 31~34℃;

[0045] Wherein...

Embodiment 2

[0060] Step 1 and Step 2 in Example 2 are the same as in Example 1, the difference is that Step 3 is specifically: at the end of October in the lunar calendar, use the mature unsalted soy sauce fermented grains obtained in Step 2 to make salt-free soy sauce, according to Add 85kg of mature unsalted soy sauce grains to the ratio of 100kg of water to 6kg of sucrose, mix and boil, then fully stir and soak for 20 hours after cooling, then wrap it with filter cloth and press to obtain 80-110kg of unsalted raw soy sauce, and then make the unsalted raw juice The soy sauce is transferred into a shallow tank with a depth of 80 cm, and fully fermented in a closed sun shed to obtain a salt-free original flavor soy sauce.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com