A three-phase asynchronous motor controller and a control method based on slip automatic optimization

A motor controller, three-phase asynchronous technology, applied in motor generator control, motor control, AC motor control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

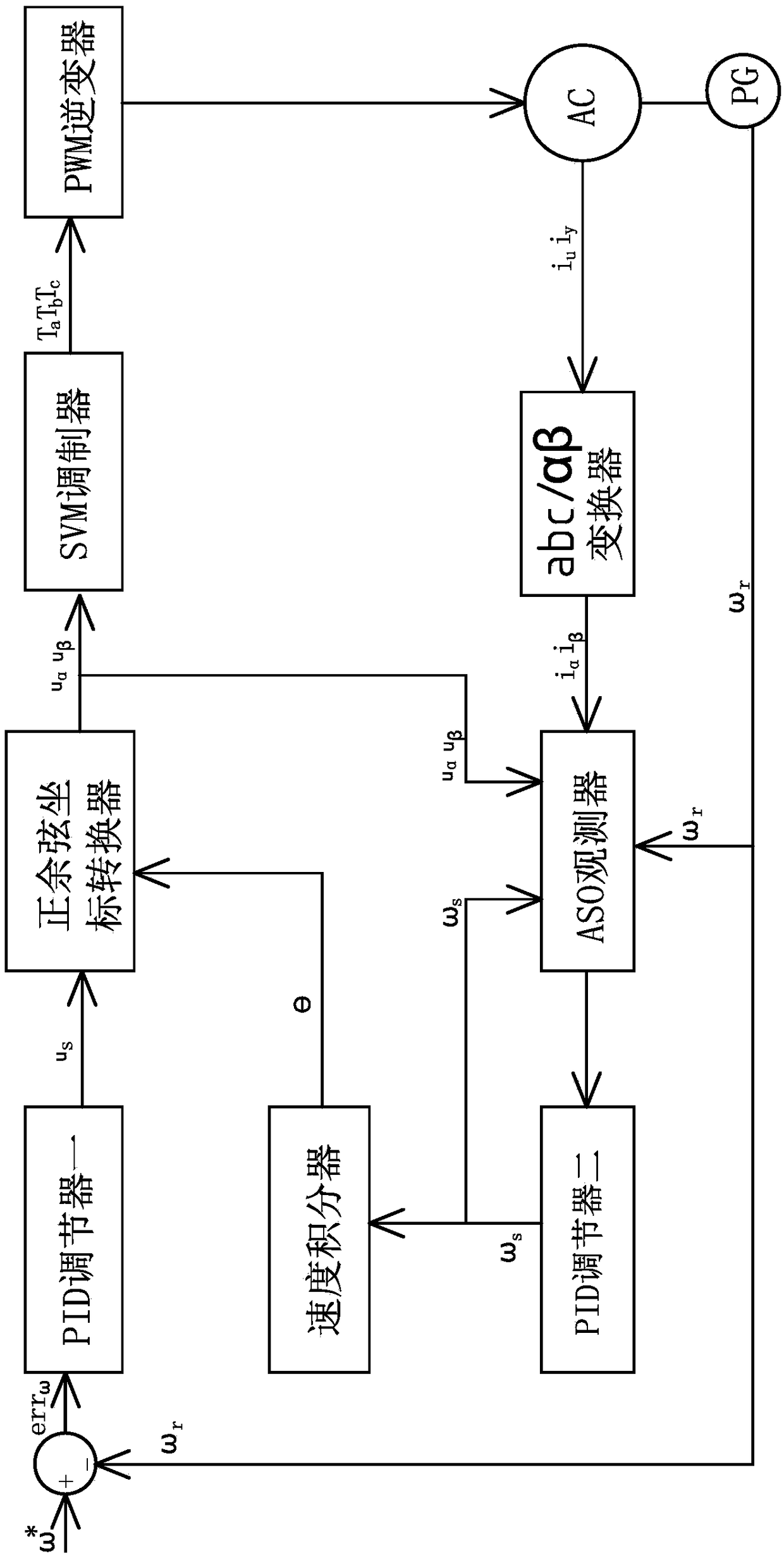

[0040] Such as Figure 1-2 As shown, this three-phase asynchronous motor controller based on slip automatic optimization includes

[0041] PID regulator 2: used to obtain the angular frequency command ω * and rotor rotation angular frequency ω r The difference err ω And generate the corresponding stator reference voltage u after adjustment s ;

[0042] Velocity Integrator: Used to rotate the angular frequency ω according to the stator voltage vector s After integration, the corresponding control angle θ is obtained;

[0043] Sin-cosine coordinate converter: connected to the output terminal of PID regulator 2 and speed integrator, used for reference voltage u according to the stator s and the stator control angle θ to gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com