A terminal with an operating handle

A terminal block and operating handle technology, which is applied in the field of wiring clips, can solve problems such as short service life, high production cost, and poor clamping stability, so as to improve stability and service life, facilitate wiring and pulling out, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

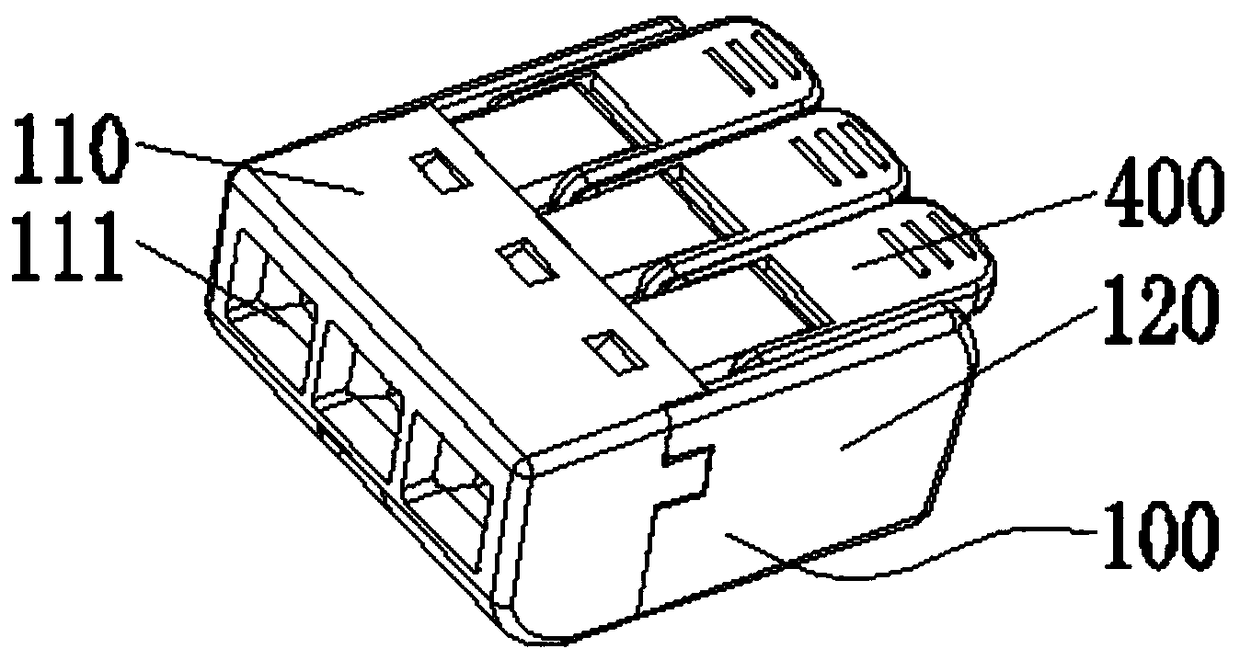

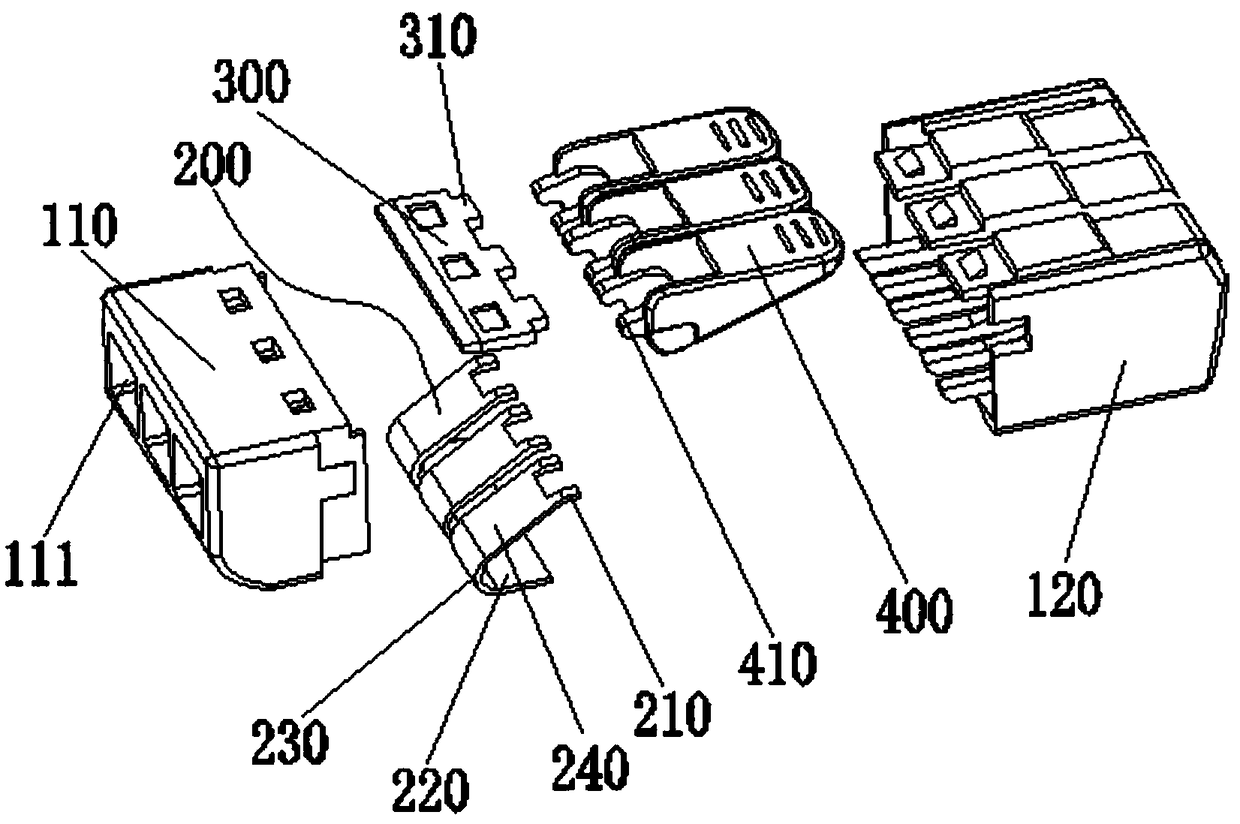

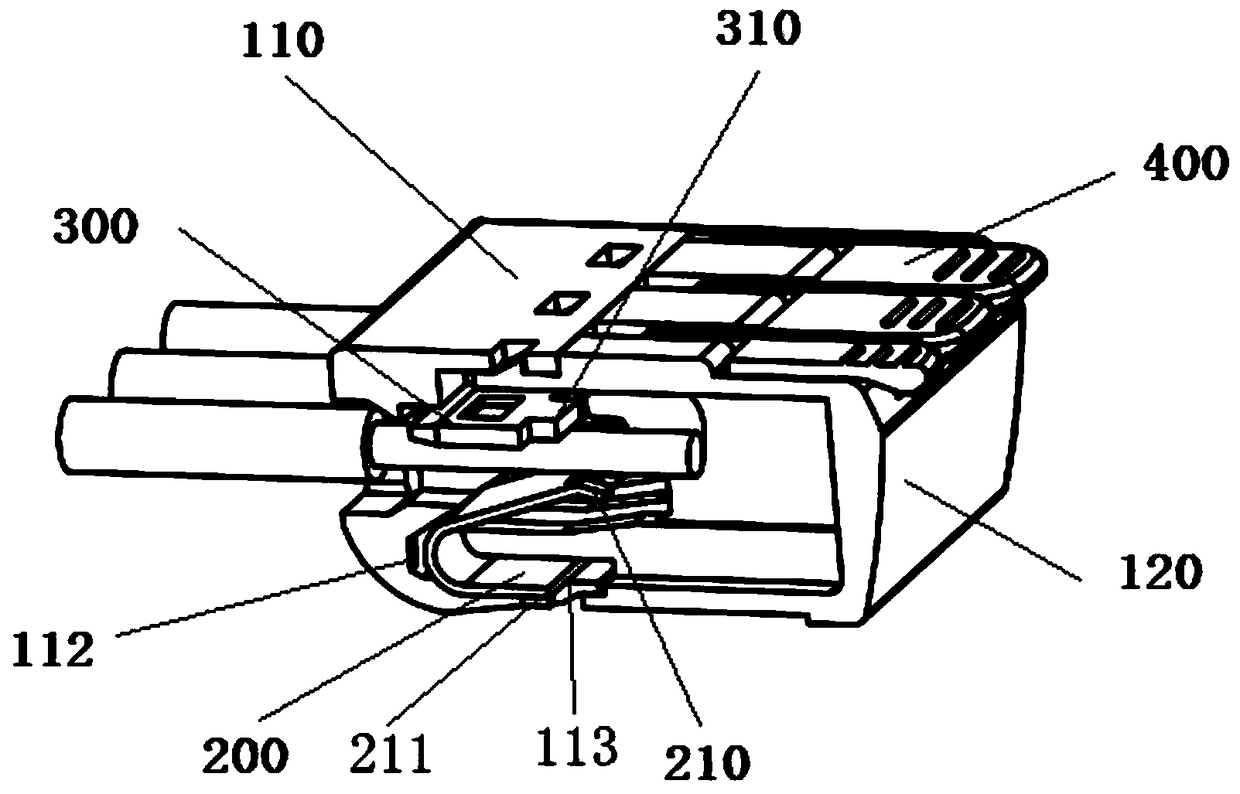

[0015] Such as Figure 1-Figure 4 As shown, a terminal with an operating handle includes a housing 100. The housing 100 is provided with at least two independent chambers, and the chambers are equipped with elastic pieces 200 and conductive pieces 300. The above-mentioned conductive sheet 300 runs through all the chambers and cooperates with the shrapnel 200 to clamp the wires. The upper end of the housing 100 corresponding to the chamber is equipped with a handle 400. The handle 400 has a normal state and a working state. When the handle When the 400 is in the working state, the handle 400 presses the elastic piece 200 to cause elastic deformation of the elastic piece 200 , the elastic piece 200 is provided with a barb 210 , and the elastic piece 200 is limitedly assembled with the housing 100 . The normal state of the handle means that there is no contact between the handle and the shrapnel. In this state, the shrapnel and the conductive sheet can block the wire. The working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com