Ag nanowire/polyurethane flexible transparent conductive composite film and preparation method thereof

A technology of transparent conduction and polyurethane, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of nano-silver wire compounding, etc., and achieve broad application prospects and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of Ag nanowire / polyurethane flexible transparent conductive composite film, comprising the following steps:

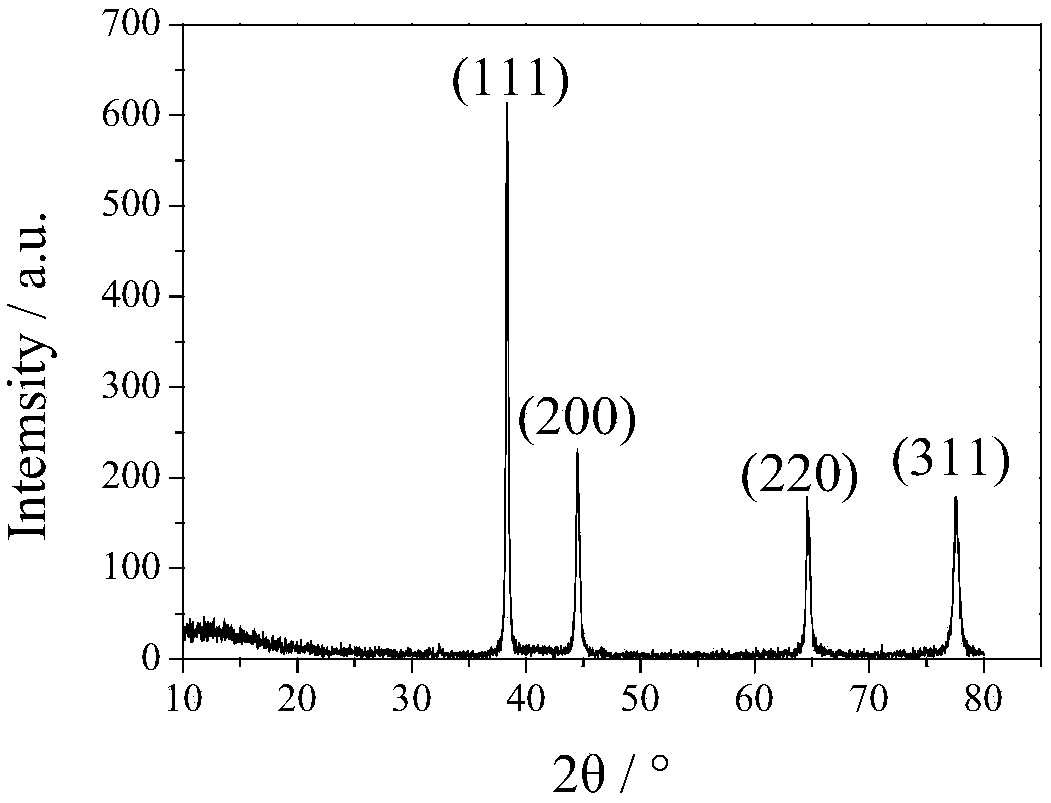

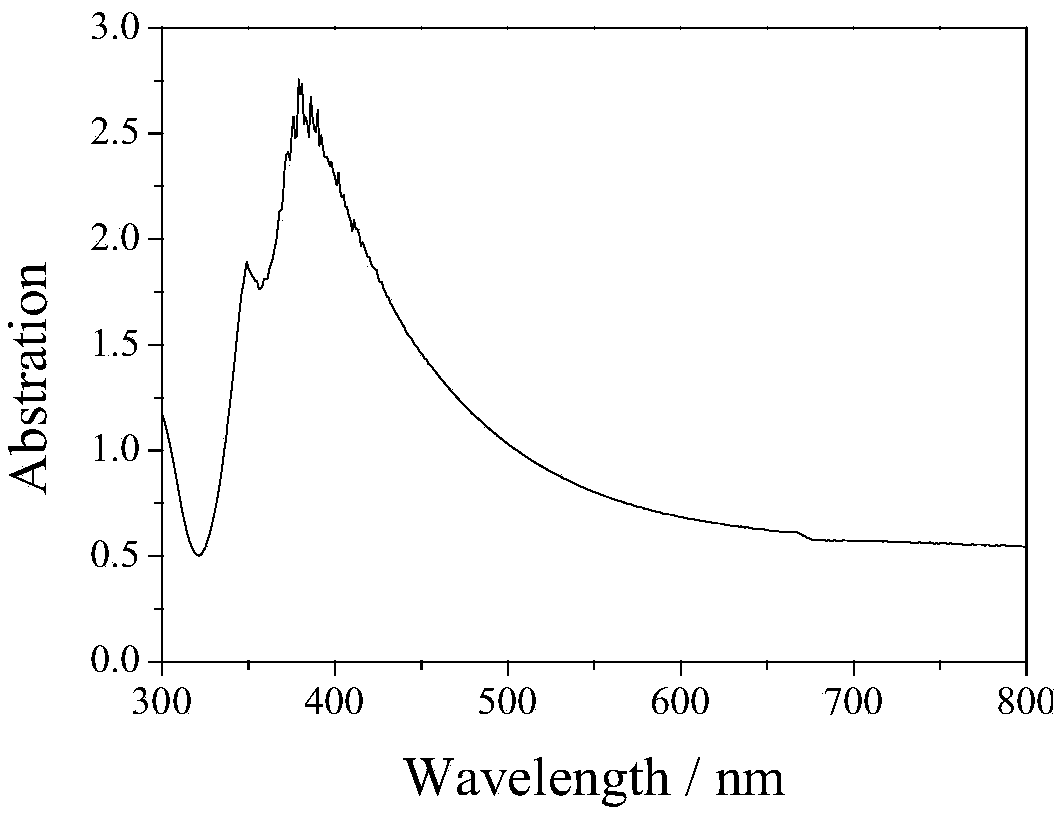

[0045] Step 1: Dissolve 0.54g of polyvinylpyrrolidone (PVP) and 1.1mg of sodium chloride in an oil bath at 120°C until completely dissolved in 25mL of ethylene glycol (EG) to form a solution A. 0.27g silver nitrate (AgNO 3 ) was stirred at room temperature until completely dissolved in 15 mL of ethylene glycol (EG) to form a B solution. Add solution A drop by drop into solution B, and keep stirring solution B during this period to obtain solution C. Then pour solution C into a 50mL autoclave, put it in a constant temperature blast drying oven at 140°C for 3 hours, take out the solution, add an appropriate amount of ethanol and centrifuge two to three times.

[0046] Step 2: Weigh 0.938g MDI and 3g PEG-2000, and measure 10mL DMF. Pass N 2 Remove the air in the flask and set the temperature of the water bath to 70°C, take out PEG-2000 from...

Embodiment 2

[0050] A preparation method of Ag nanowire / polyurethane flexible transparent conductive composite film, comprising the following steps:

[0051] Step 1: Dissolve 0.8g of polyvinylpyrrolidone (PVP) and 2.2mg of sodium chloride in an oil bath at 120°C until completely dissolved in 25mL of ethylene glycol (EG) to form a solution A. 0.27g silver nitrate (AgNO 3 ) was stirred at room temperature until completely dissolved in 15 mL of ethylene glycol (EG) to form a B solution. Add solution A drop by drop into solution B, and keep stirring solution B during this period to obtain solution C. Then pour the C solution into a 50mL autoclave, put it in a constant temperature blast drying oven at 160°C for 4 hours, take out the solution, add an appropriate amount of ethanol and centrifuge for two to three times.

[0052] Step 2: Weigh 1.126g MDI and 3g PEG-2000, and measure 15mL DMF. Pass N 2 Remove the air in the flask and set the temperature of the water bath to 75°C, take out PEG-20...

Embodiment 3

[0056] A preparation method of Ag nanowire / polyurethane flexible transparent conductive composite film, comprising the following steps:

[0057] Step 1: Dissolve 1.08g of polyvinylpyrrolidone (PVP) and 4.4mg of sodium chloride in an oil bath at 120°C until completely dissolved in 25mL of ethylene glycol (EG) to form a solution A. 0.27g silver nitrate (AgNO 3 ) was stirred at room temperature until completely dissolved in 15 mL of ethylene glycol (EG) to form a B solution. Add solution A drop by drop into solution B, and keep stirring solution B during this period to obtain solution C. Then pour the C solution into a 50ml high-pressure reaction kettle, put it in a constant temperature blast drying oven at 180°C for 5 hours, take out the solution, add an appropriate amount of ethanol and centrifuge it for two to three times.

[0058] Step 2: Weigh 1.3138g MDI and 3g PEG-2000, and measure 20mL DMF. Pass N 2 Remove the air in the flask and set the temperature of the water bath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com