Power source heat dissipation and waste heat utilization system of hybrid electric vehicle and control method

A technology of hybrid electric vehicles and control methods, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve problems such as excessive temperature of power batteries and no use of waste heat, etc., to ensure normal working conditions and protect service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

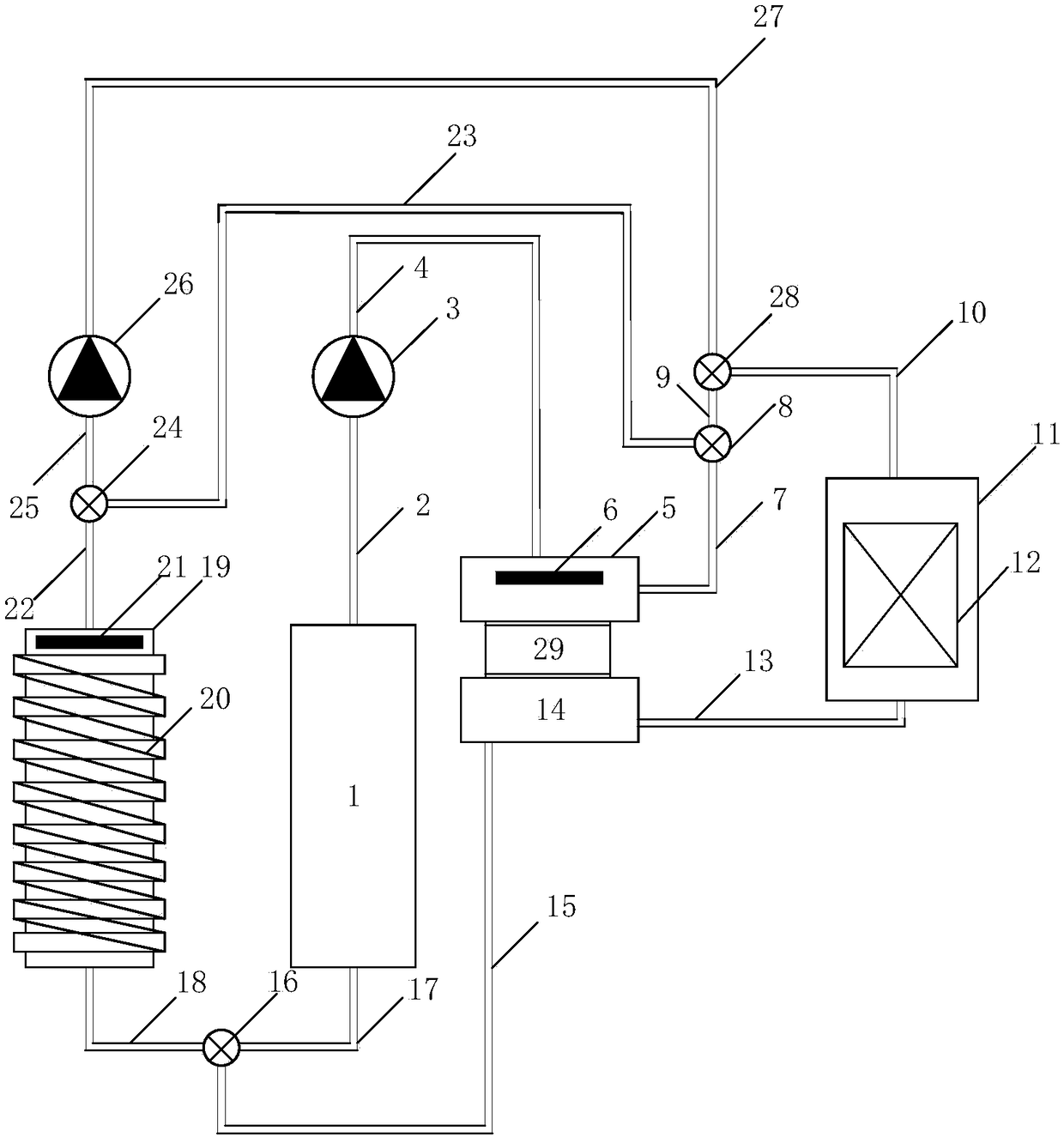

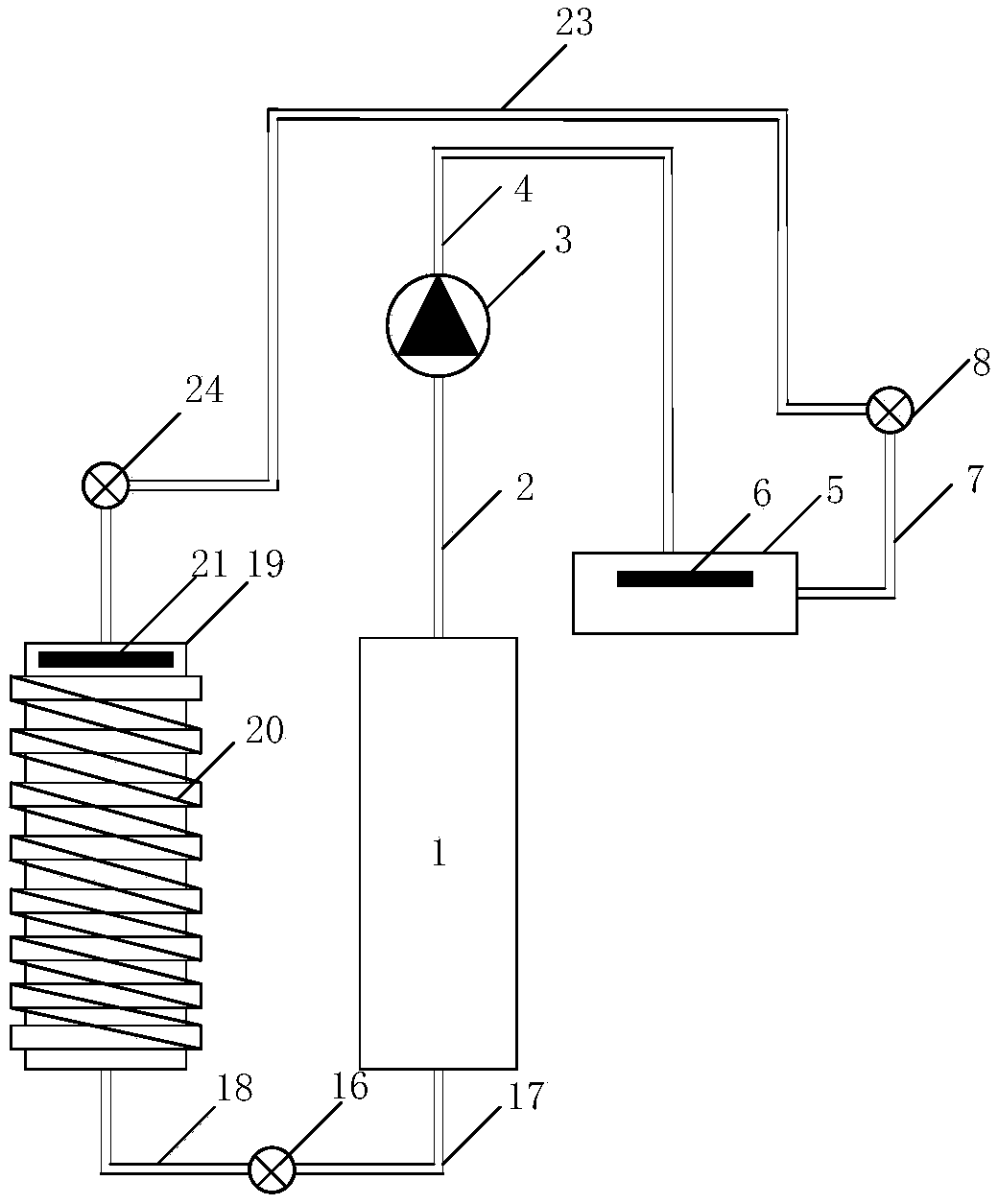

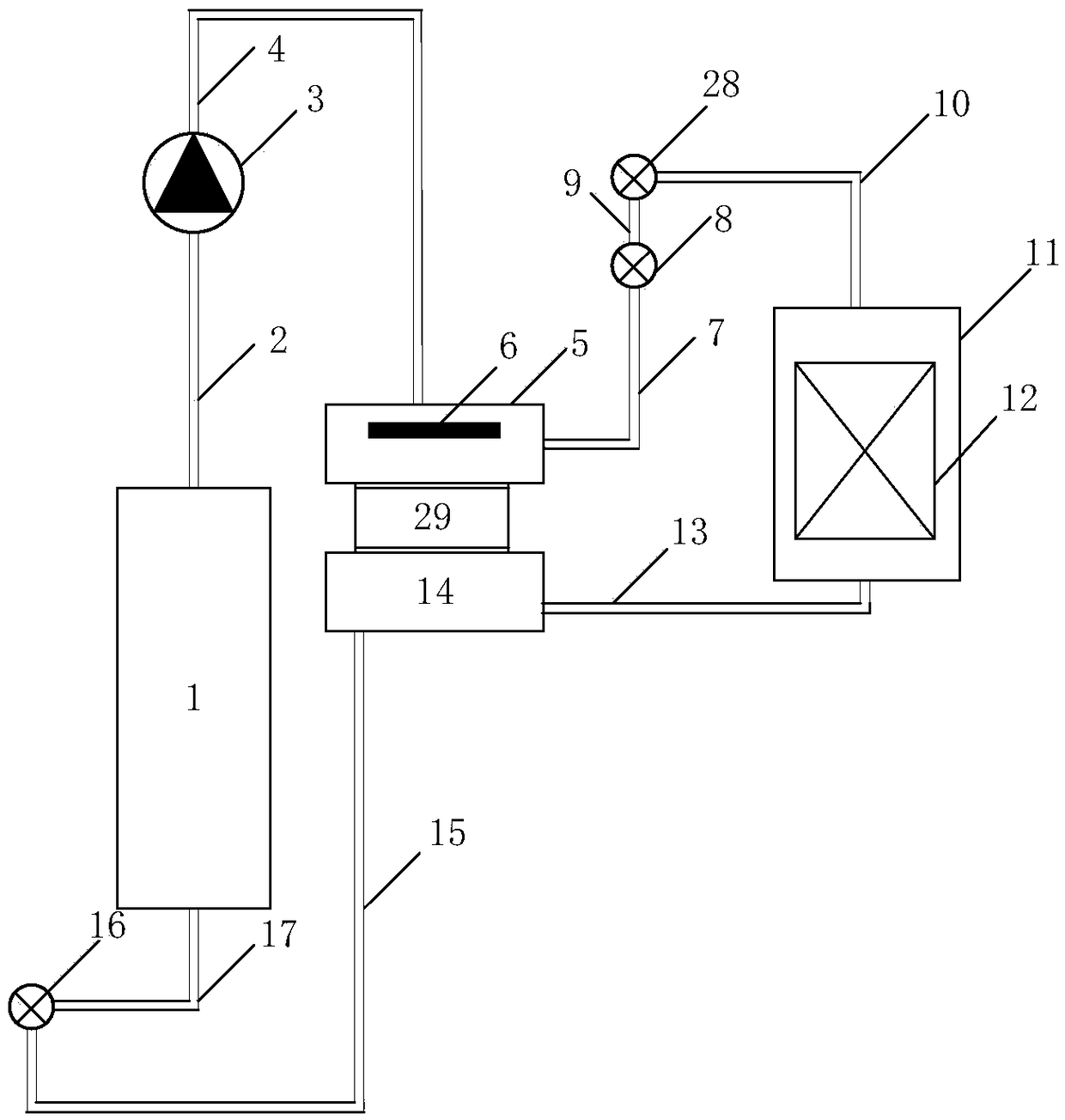

[0025] For further understanding of the present invention, now in conjunction with the attached Figure 1-4 The present invention is further described:

[0026] combined with figure 1, a waste heat utilization and cooling system for a hybrid vehicle, comprising an engine body 1 and a power battery 19, the engine body 1 is connected to the water inlet end of a first water pump 3 through a first connecting pipe 2; The water outlet is connected with one end of the second connecting pipe 4; the other end of the second connecting pipe 4 is connected with the water inlet of the first water tank 5, and the first water tank 5 is provided with a first temperature sensor 6, and the first water tank The water outlet of 5 is connected with one end of the third connecting pipe 7, the other end of the third connecting pipe 7 is connected with one end of the first electromagnetic valve 8, and the other two ends of the first electromagnetic valve 8 are connected with the fourth connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com