A support method for the roof of goaf in underground coal mine

A technology for roof support and goaf, which is applied in shaft equipment, shaft lining, mining equipment, etc., can solve the problems of difficulty in controlling the contact density between filling body and roof, ground building damage, roof damage and collapse, etc. Achieve light weight, reduce coal mining cost, and small subsidence deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

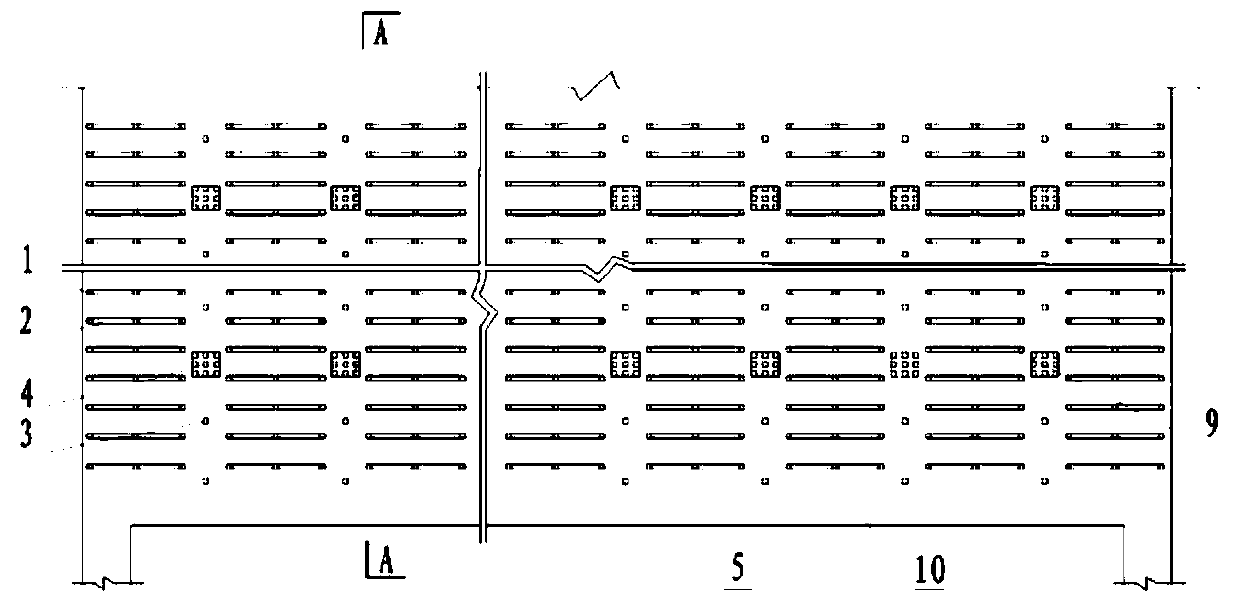

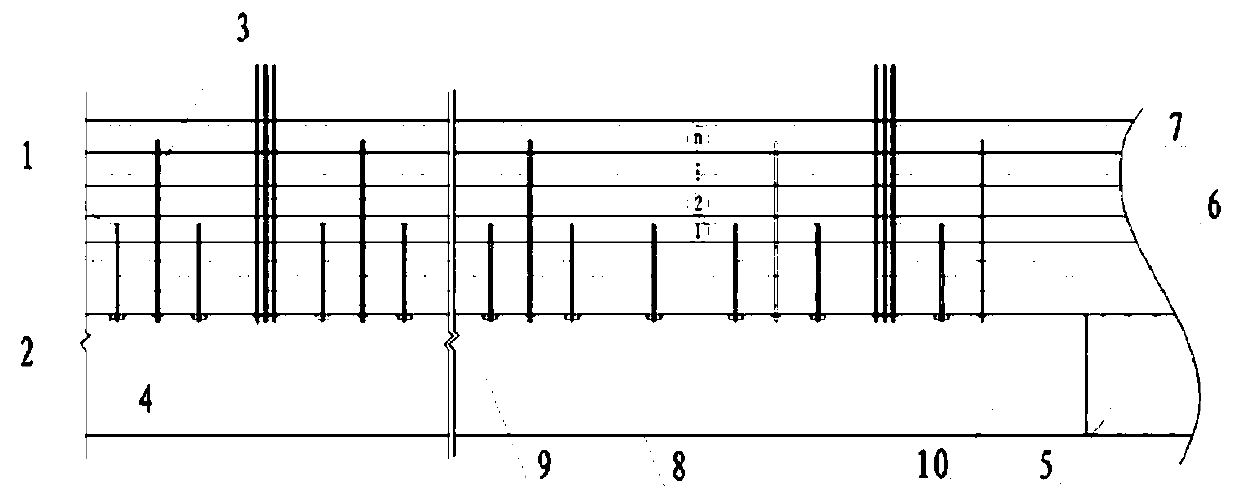

[0048] The method for supporting the roof of the coal mine goaf under the coal mine proposed by the present invention comprises the following steps:

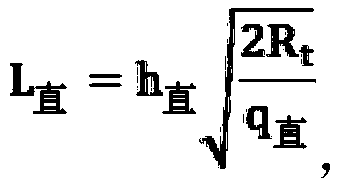

[0049] (1) Calculating the initial caving step distance L of the direct top 6 of the underground coal mining face by using the mine pressure theory 直 :

[0050]

[0051] Among them, h 直 is the thickness of the immediate top rock, R t is the tensile strength of the directly topped rock, q 直 is the direct top 6 load, q 直 = r 直 h 直 , r 直 is the body force directly against the rock, R t and r 直 Obtained from relevant manuals according to the type of direct top rock;

[0052] Using mine pressure theory to calculate the initial fracture step distance L of Laoding 7 in underground coal mining face 老1 :

[0053]

[0054] Among them, h 老1 is the rock thickness of the first layer of Laoding 7, R t1 is the tensile strength of Laoding 7 rock, obtained from relevant manuals according to the rock type of the first layer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com