Processing method for improving quality of jute fibers

A technology of jute fiber and processing method, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc. It can solve the problems of not improving the quality of jute fiber, restricting the development and utilization of product performance, and vicious competition, so as to improve the market prospect and economic value, improved textile properties, and the effect of deepening performance characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

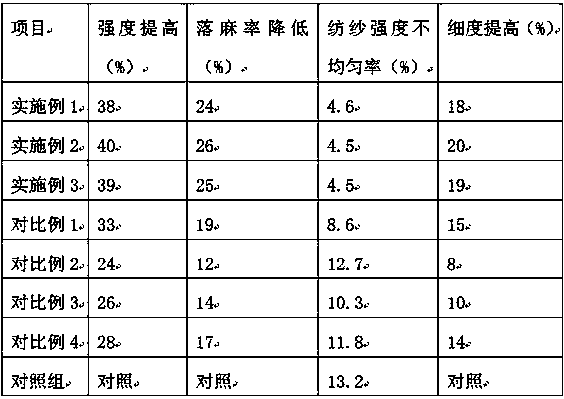

Examples

Embodiment 1

[0017] A processing method for improving jute fiber quality, comprising the following steps:

[0018] (1) Place the jute fiber after rinsing in the mixed solvent of potassium acetate-ethanol, stir and mix for 15 minutes at 300 rpm, add fiber modifier, the dosage is 5.0% of the mass of the mixed solvent, the fiber modified The agent is made of the following components in parts by weight: 13 parts of zinc acetate, 6.0 parts of borax, 5.0 parts of sulfamic acid, 4.0 parts of sodium abietate soap, 2.3 parts of cetyltrimethylammonium chloride, dimethylol Urea accounts for 1.4 parts, sodium hydroxide accounts for 1.0 parts, sodium tripolyphosphate accounts for 1.0 parts, and water 600 parts;

[0019] (2) Heat the mixed material in step (1) to 40°C, add turpentine-ethanol mixed defoamer dropwise, keep warm and stir at a low speed for 1 hour at a stirring speed of 80 rpm, then place it in a centrifuge at 1500 rpm Centrifuge for 10 minutes at 10 minutes, pour off the supernatant, cont...

Embodiment 2

[0026] A processing method for improving jute fiber quality, comprising the following steps:

[0027] (1) Place the jute fiber after rinsing in potassium acetate-ethanol mixed solvent, stir and mix for 18 minutes at 330 rpm, add fiber modifier, the amount is 5.3% of the mixed solvent quality, the fiber modified The agent is made of the following ingredients in parts by weight: 14 parts of zinc acetate, 6.5 parts of borax, 5.5 parts of sulfamic acid, 4.2 parts of sodium abietate soap, 2.4 parts of cetyltrimethylammonium chloride, dimethylol Urea accounts for 1.5 parts, sodium hydroxide accounts for 1.2 parts, sodium tripolyphosphate accounts for 1.1 parts, and water 650 parts;

[0028] (2) Heat the mixed material in step (1) to 42°C, add turpentine-ethanol mixed defoamer dropwise, keep warm and stir at a low speed for 1.5 hours at a stirring speed of 90 rpm, then place it in a centrifuge at 1600 rpm Centrifuge for 11 minutes at 10 minutes, pour off the supernatant, continue ce...

Embodiment 3

[0035] A processing method for improving jute fiber quality, comprising the following steps:

[0036] (1) Place the jute fiber after rinsing in potassium acetate-ethanol mixed solvent, stir and mix for 20 minutes at 350 rpm, add fiber modifier, the amount is 5.5% of the mixed solvent quality, the fiber modified The agent is made of the following ingredients in parts by weight: 16 parts of zinc acetate, 7.0 parts of borax, 6.0 parts of sulfamic acid, 4.5 parts of sodium abietate soap, 2.5 parts of cetyltrimethylammonium chloride, dimethylol Urea accounted for 1.6 parts, sodium hydroxide accounted for 1.4 parts, sodium tripolyphosphate accounted for 1.2 parts, and water 700 parts;

[0037] (2) Heat the mixed material in step (1) to 45°C, add turpentine-ethanol mixed defoamer dropwise, keep warm and stir at a low speed for 2 hours at a stirring speed of 100 rpm, then place it in a centrifuge at 1800 rpm Centrifuge for 12 minutes at 10 minutes, pour off the supernatant, continue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com