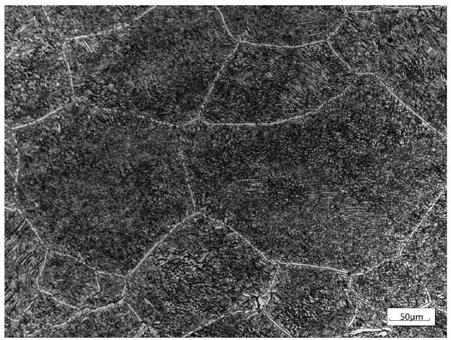

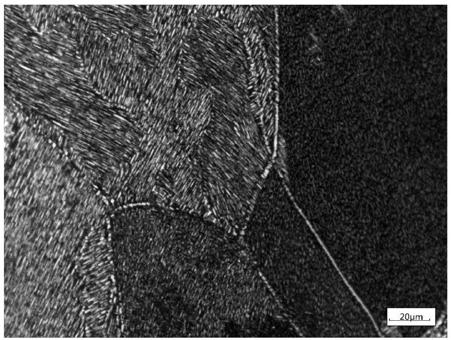

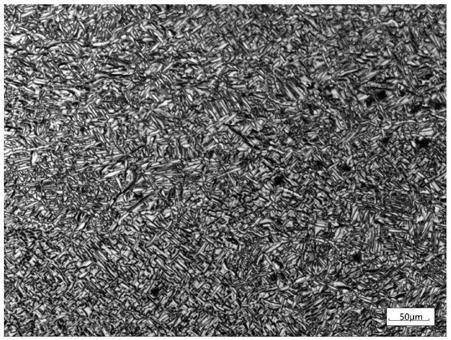

Prediction method for titanium alloy die forging part basket-weave microstructure distribution

A basket organization and prediction method technology, applied in the direction of instruments, electrical digital data processing, special data processing applications, etc., can solve the problems of lack of visual model, temperature, and deformation quantitative dependence are not clear, so as to reduce the number of non-network baskets The generation of organization, the improvement of material utilization and the effect of improving the performance of forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Exemplary embodiments, features, and aspects of the present invention will be described in detail below with reference to the accompanying drawings. The same reference numbers in the figures indicate functionally identical or similar elements. While various aspects of the embodiments are shown in drawings, the drawings are not necessarily drawn to scale unless specifically indicated.

[0057] Specifically, the present invention provides a method for predicting the distribution of basket structure of titanium alloy die forgings, the steps are as follows:

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com