Production method for aluminum killed molten steel containing sulfur

A production method and technology of molten steel, applied in the direction of improvement of process efficiency, manufacture of converters, etc., can solve the problems of not being able to meet the normal casting of slab continuous casting machines, difficulty in inclusion control, etc., to achieve easy removal by floating and avoid CaS inclusions , The effect of product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

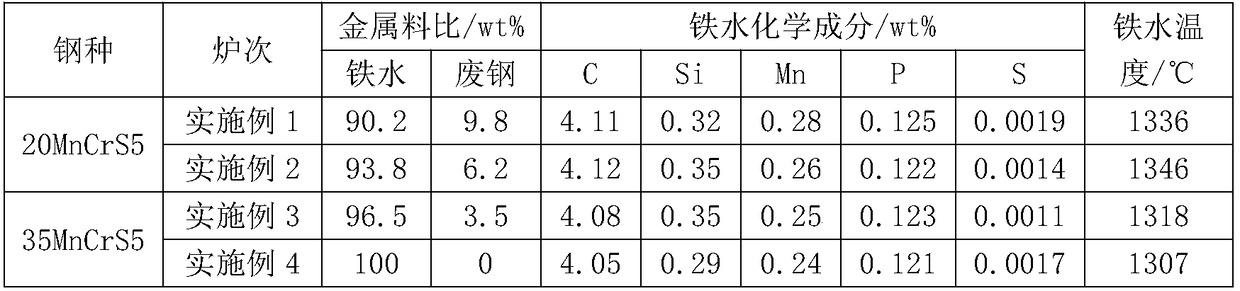

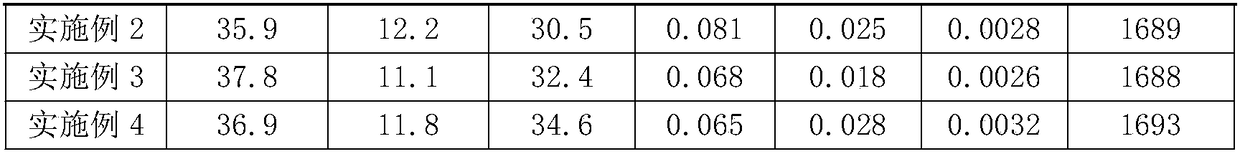

[0020] In the embodiment of the present invention, a 150-ton top-bottom double-blown converter is used to smelt sulfur-containing aluminum-killed molten steel, wherein, the smelted steel grades in Examples 1 and 2 are both 20MnCrS5, and the smelted steel grades in Embodiment 3 and 4 are both 35MnCrS5. The converter smelting process The bottom blowing gas is argon; the production methods include: converter smelting, LF furnace refining and RH furnace refining. The control parameters of the molten steel production in the embodiment of the present invention are shown in Table 1 to Table 5.

[0021] Table 1 Parameters of converter smelting metal material in the embodiment of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com