A water-based high-efficiency heat dissipation coating based on graphene oxide and preparation method thereof

A heat-dissipating coating and graphene technology, applied in the coating and other directions, can solve the problems of poor heat-dissipating effect, weak adhesion, poor weather resistance, etc. The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

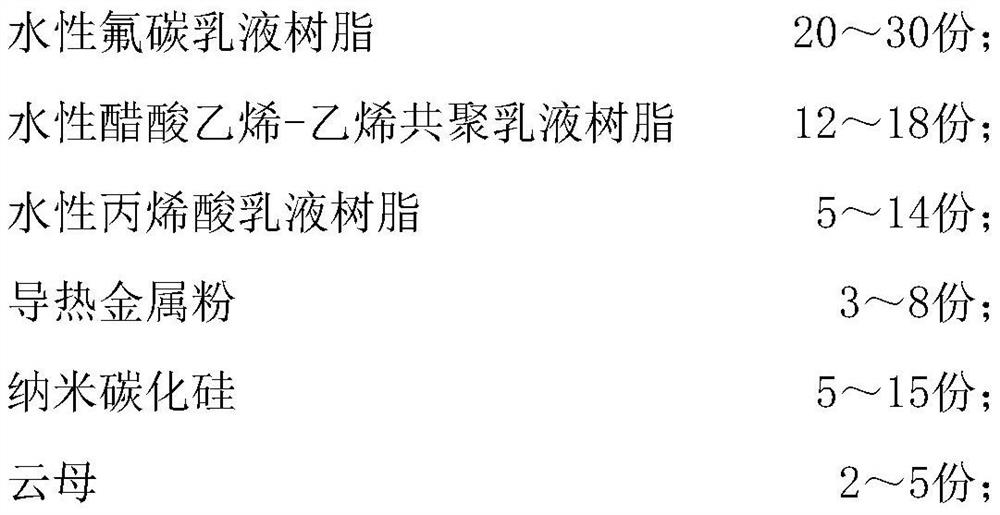

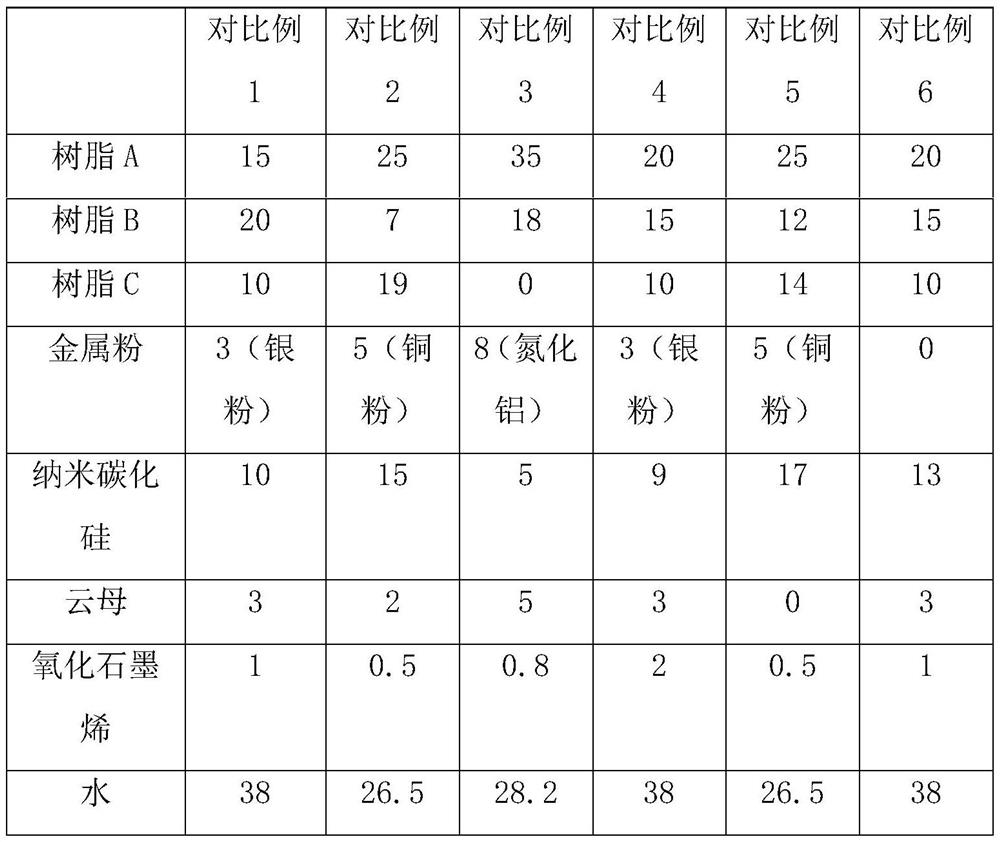

[0030] Examples 1-5 provide a graphene oxide-based water-based high-efficiency heat dissipation coating, and the components and parts by mass are shown in Table 1.

[0031] Wherein, resin A is water-based fluorocarbon emulsion resin, resin B is water-based vinyl acetate-ethylene copolymer emulsion resin, and resin C is water-based acrylic emulsion resin;

[0032] The heat-conducting metal powder is one or more combinations of silver powder, copper powder, aluminum powder, aluminum nitride and silicon nitride, and the particle size of the heat-conducting metal powder is 1-10 μm.

[0033] The heat-conducting metal powder is subjected to physical coating modification treatment; the method of physical coating modification treatment includes the following steps: adding heat-conducting metal powder to the SLG continuous powder surface modification machine, performing mechanical dispersion for 0.5-1h, and then Add a surface modifier for surface modification treatment, control the tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com