Method for extracting livetin and oil from larimichthys crocea eggs at the same time

A technology of yolk protein and large yellow croaker, which is applied in the field of simultaneous extraction of yolk protein and oil from large yellow croaker eggs, and the preparation of large yellow croaker egg yolk protein and oil, can solve the unsolved problems of preparing large yellow croaker egg yolk protein and oil, waste of resources, environment, Waste of resources and other issues, to achieve the effects of preservation, reduce pollution, improve utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

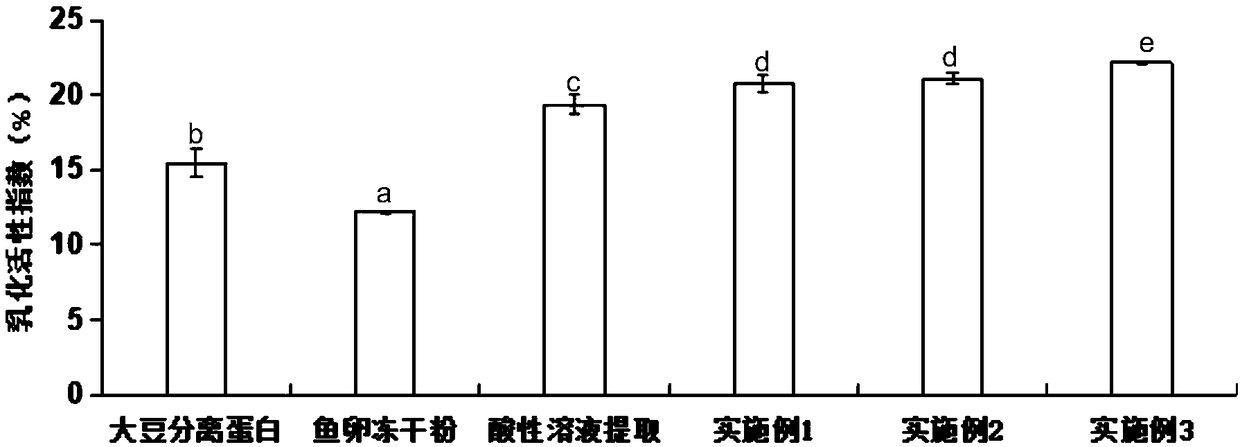

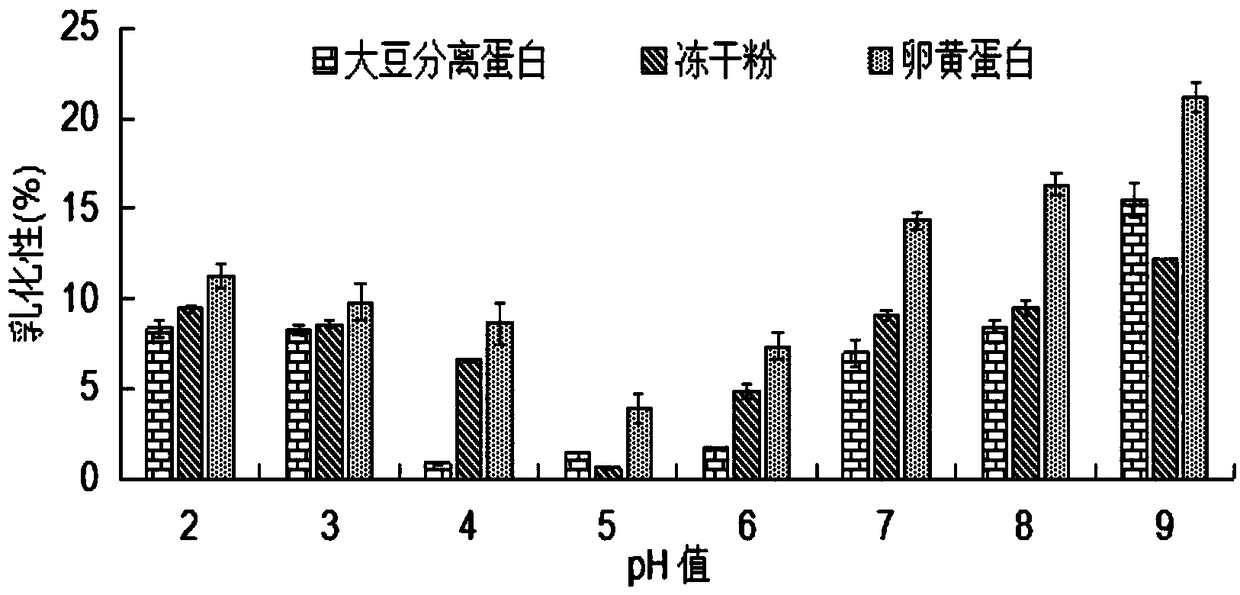

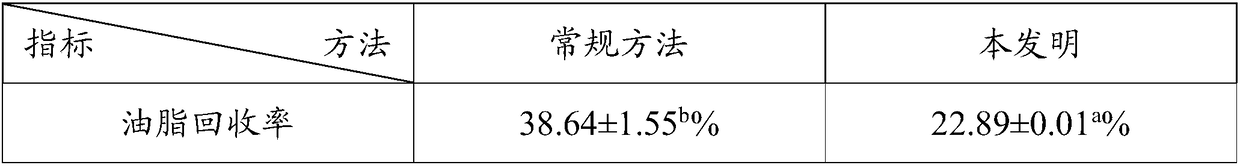

Examples

Embodiment 1

[0044] S1. Preparation of large yellow croaker roe freeze-dried powder: Homogenize large yellow croaker roe at 1000rpm for 5 minutes, vacuum freeze-dry the homogenate at 1Pa and -25°C for 72 hours to obtain large yellow croaker roe freeze-dried powder;

[0045] S2. Dissolving the freeze-dried powder: the freeze-dried powder obtained in step S1 was dissolved in a sodium chloride solution with a concentration of 0.6M at a weight ratio of 1:10, and the pH was adjusted to 7 using a sodium hydroxide solution;

[0046] S3, primary extraction: Stir the solution obtained in step S2 at 300rpm for 2h, centrifuge at 8000g for 20min, and collect the upper layer oil, the middle layer liquid and the sediment respectively; the upper layer oil is grease, and the middle layer liquid is egg yolk protein salt solution.

[0047] S4. Dissolving the precipitate: the precipitate obtained in step S3 is dissolved in a sodium chloride solution with a concentration of 0.6M at a weight ratio of 1:10, and...

Embodiment 2

[0054] S1. Preparation of large yellow croaker roe freeze-dried powder: Homogenize large yellow croaker roe for 4 minutes at 1500 rpm, vacuum freeze-dry the homogenate at 2.5 Pa and -30°C for 66 hours, and obtain large yellow croaker roe freeze-dried powder;

[0055] S2. Dissolving the freeze-dried powder: the freeze-dried powder obtained in step S1 was dissolved in a sodium chloride solution with a concentration of 0.8M at a weight ratio of 1:15, and the pH was adjusted to 8 using a sodium hydroxide solution;

[0056] S3, primary extraction: Stir the solution obtained in step S2 at 400rpm for 1.5h, centrifuge at 9000g for 15min, collect the upper layer oil, the middle layer liquid and the precipitation respectively; the upper layer oily matter is grease, and the middle layer liquid is egg yolk protein saline solution.

[0057] S4. Dissolving the precipitate: the precipitate obtained in step S3 is dissolved in a sodium chloride solution with a concentration of 0.8M at a weight...

Embodiment 3

[0064] S1. Preparation of large yellow croaker roe freeze-dried powder: Homogenize the large yellow croaker roe for 3 minutes at 2000 rpm, vacuum freeze-dry the homogenate at 5 Pa and -50°C for 60 hours, and obtain the large yellow croaker roe freeze-dried powder;

[0065] S2, dissolving the freeze-dried powder: dissolving the freeze-dried powder obtained in step S1 in a sodium chloride solution with a concentration of 1.0M at a weight ratio of 1:20, and adjusting the pH to 9 with a sodium hydroxide solution;

[0066] S3, primary extraction: Stir the solution obtained in step S2 at 500rpm for 1h, centrifuge at 10000g for 15min, collect the upper layer oil, the middle layer liquid and the precipitation respectively; the upper layer oil is grease, and the middle layer liquid is egg yolk protein salt solution.

[0067] S4. Dissolving the precipitate: the precipitate obtained in step S3 is dissolved in a sodium chloride solution with a concentration of 1M at a weight ratio of 1:20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com