Method for tracking constant force surface of robot based on fuzzy iterative algorithm

An iterative algorithm and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as stagnation in simulation, large fluctuations, unstable contact force between robots and surfaces, and achieve simple results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

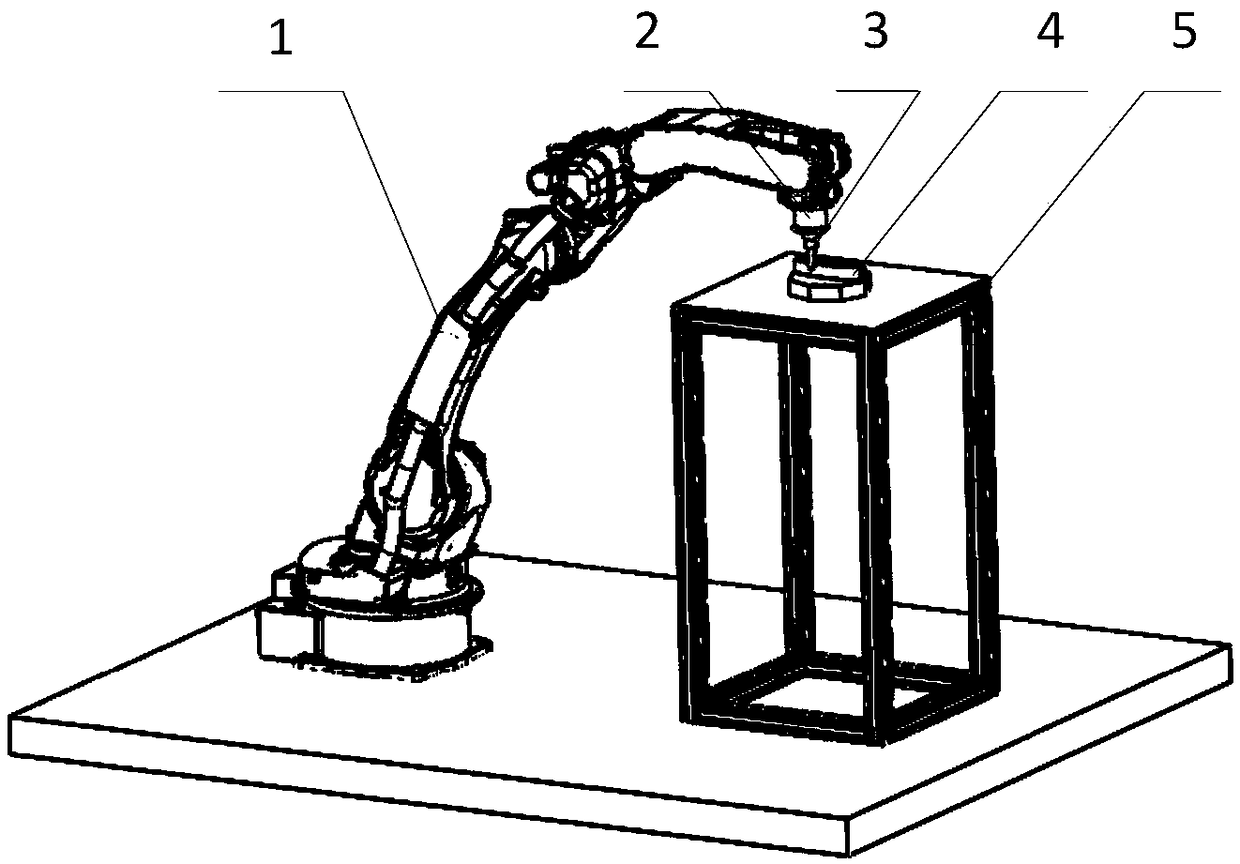

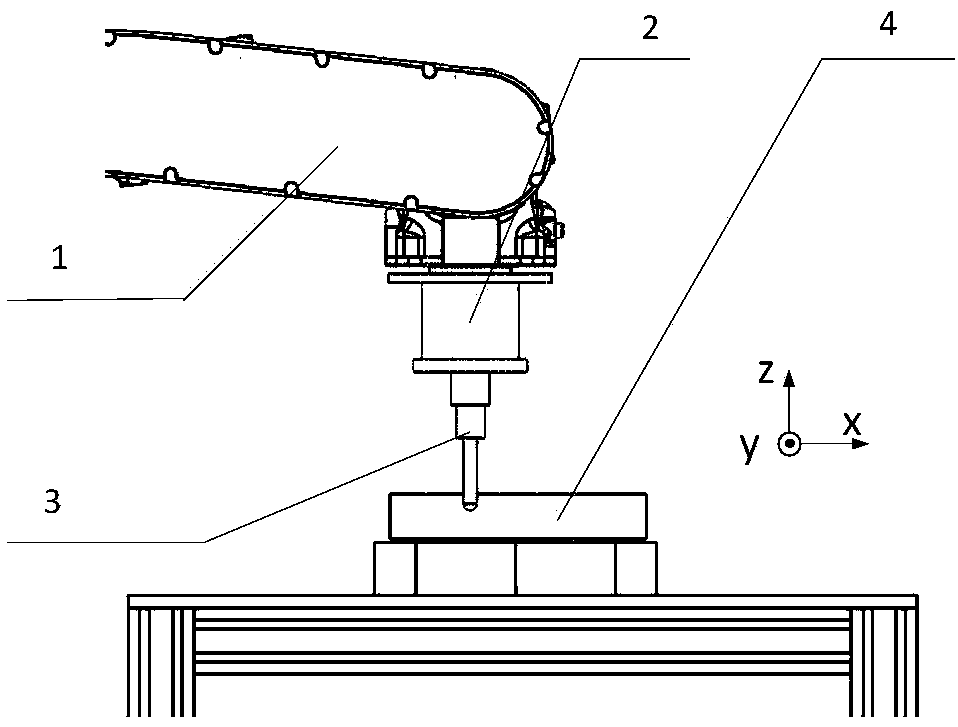

[0040] A robot constant force surface tracking method based on fuzzy iterative algorithm. The method is based on a robot constant force tracking platform, including a six-axis industrial robot, a workbench, a curved surface workpiece, a six-dimensional force sensor, a host computer, and a data acquisition module. The robot always moves along the x direction at a constant speed. When the robot is in contact with the workpiece, it shifts along the y direction according to the magnitude of the force, and tracks along the unknown surface to ensure that the end of the robot does not leave the curved workpiece.

[0041] Specifically include the following steps:

[0042] (1) Establish the mapping relationship between the surface normal force and the known sensor coordinate system;

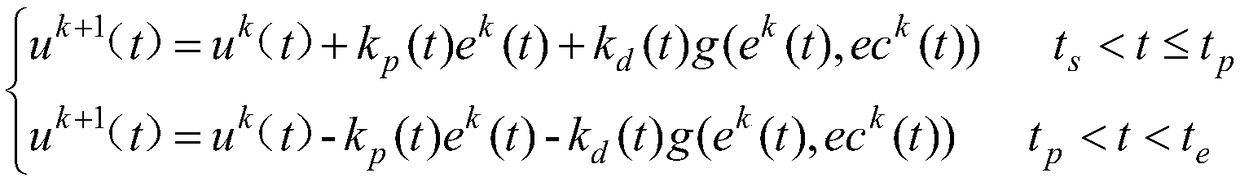

[0043] (2) Tracking along the unknown surface, the initial control algorithm is the PD algorithm, and the initial trajectory and force parameters are obtained;

[0044] (3) Obtain the trajectory and forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com