A kind of xylenesulfonic acid catalyst grinding device

A xylene sulfonic acid and grinding device technology, which is applied in grain processing and other directions, can solve problems such as poor effect, inability to meet mass production and processing, and low efficiency, so as to prevent sieve hole clogging, increase extrusion force, full grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

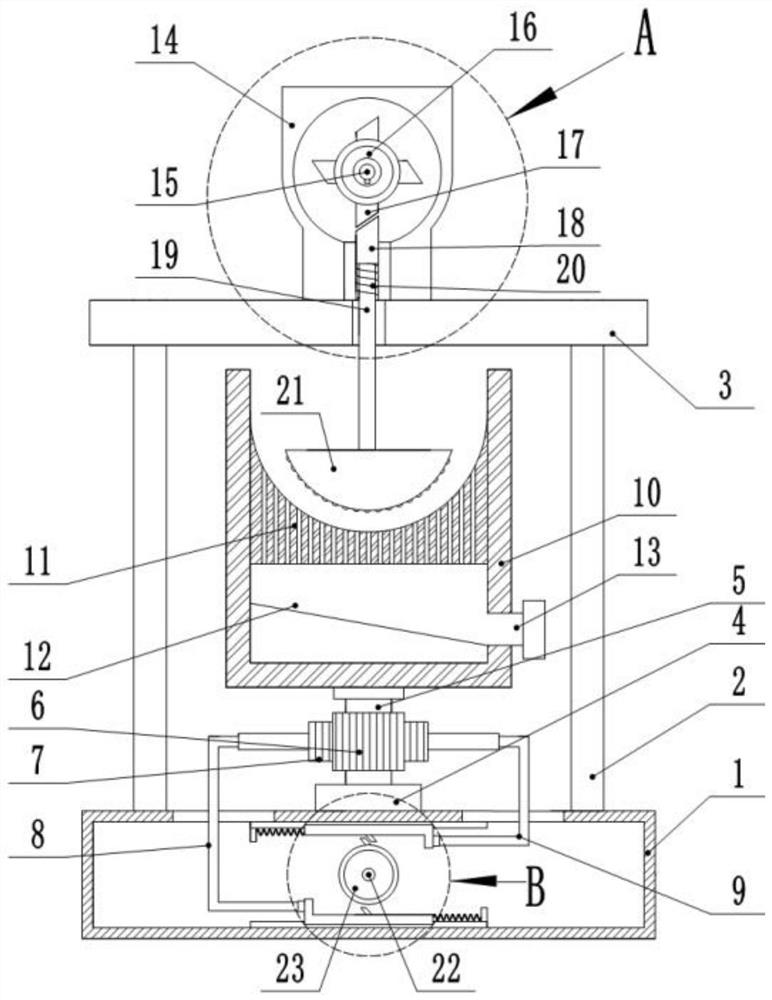

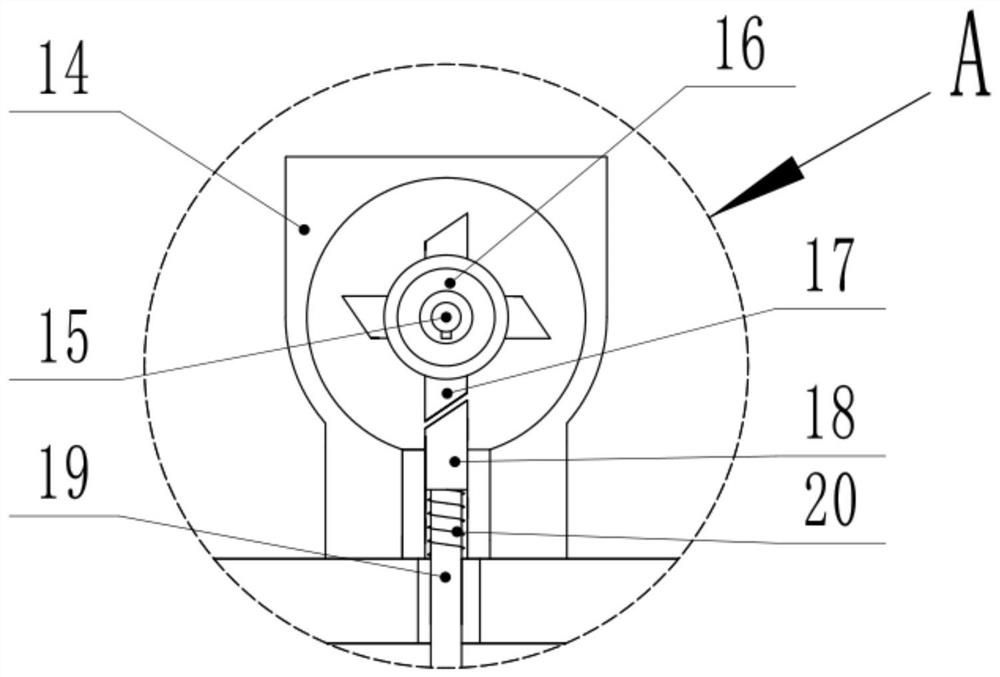

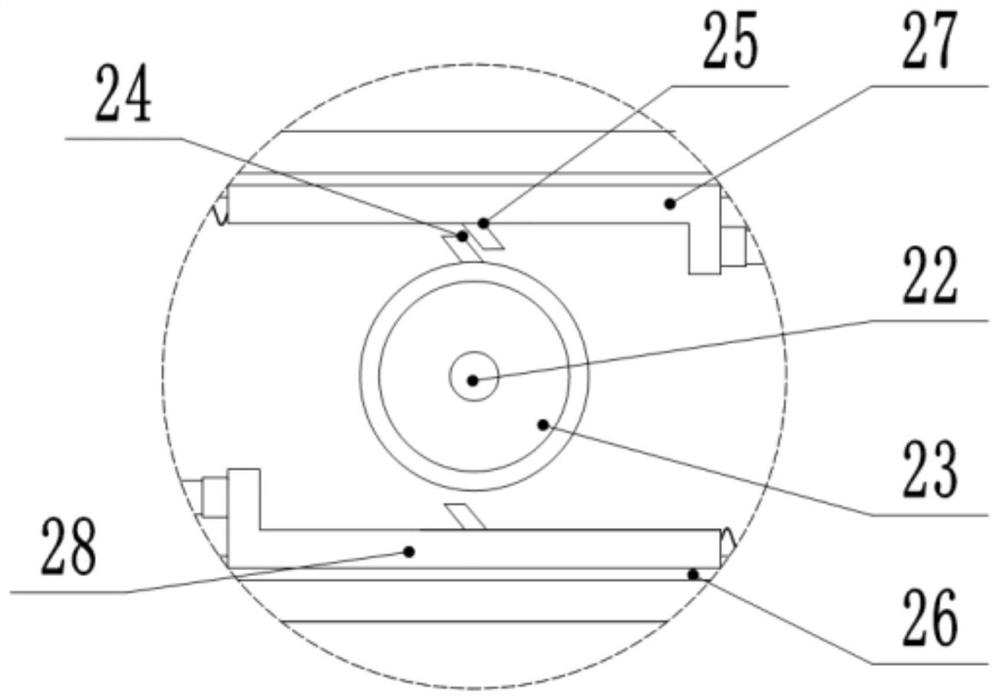

[0017] see figure 1 with image 3 , a xylene sulfonic acid catalyst grinding device, comprising a base 1, a grinding bucket 10, a grinding plate 11, an extrusion device 14 and a grinding head 21, the left and right sides of the upper surface of the base 1 are fixed with support columns 2 by bolts, The support column 2 is perpendicular to the surface of the base 1 and the upper end of the support column 2 is welded to the connecting plate 3. The center position of the base 1 is fixed with a bearing seat 4 by screws, and a rolling bearing is installed inside the bearing seat 4 for rotation, and the bearing seat 4 A rotating shaft 5 is installed on the rolling bearing with an interference fit, and a gear 6 is installed on the rotating shaft 5 with an interference fit. The upper end of the rotating shaft 5 is fixedly connected with a grinding barrel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com