Waste gas treatment device of coating mechanical equipment

A technology of waste gas treatment device and mechanical equipment, which is applied in the direction of dispersed particle separation, chemical instruments and methods, and dispersed particle filtration, etc. It can solve the problems of inability to absorb dust particles in waste gas, insufficient dust removal effect of waste gas, inconvenience of sprinkler swing, etc. problems, to achieve the effect of convenient dust removal, simple structure and high practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

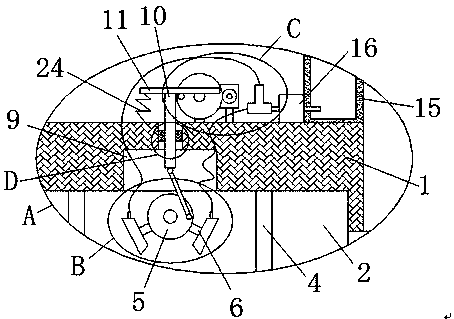

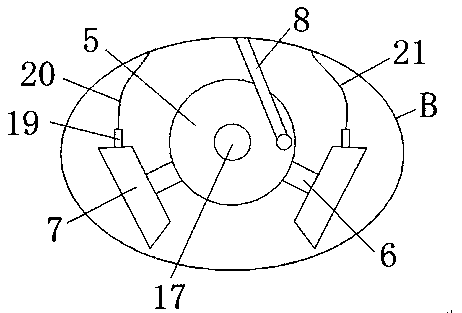

[0025] refer to Figure 1-5 In this embodiment, a waste gas treatment device for coating mechanical equipment is proposed, which includes a treatment box 1, a chamber 2 is arranged on the treatment box 1, and a horizontally arranged filter plate 3 is fixedly installed on the side wall of the chamber 2. A turntable 5 is rotatably installed in the chamber 2, and both sides of the turntable 5 are provided with a filter screen 4 fixedly installed on the side wall of the chamber 2, the bottom of the filter screen 4 is fixedly connected with the top of the filter plate 3, and the outside of the turntable 5 Two symmetrical installation rods 6 are fixedly installed, and the end of the installation rod 6 away from the turntable 5 is fixedly installed with a water mist nozzle 7, and one side of the turntable 5 is rotated with an obliquely arranged drawbar 8, and the top inner wall of the chamber 2 is provided with a There is a groove 9, the end of the drawbar 8 away from the turntable 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com