Preparation method of ZnO/GQD-PEI composite quantum dot antibacterial agent

An antibacterial agent and quantum dot technology, which is applied in the field of preparation of ZnO/GQD-PEI composite quantum dot antibacterial agent, can solve the problems of large structural difference, large size, and small number of adsorption active sites, and achieves strong drug resistance, Good biocompatibility and high antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

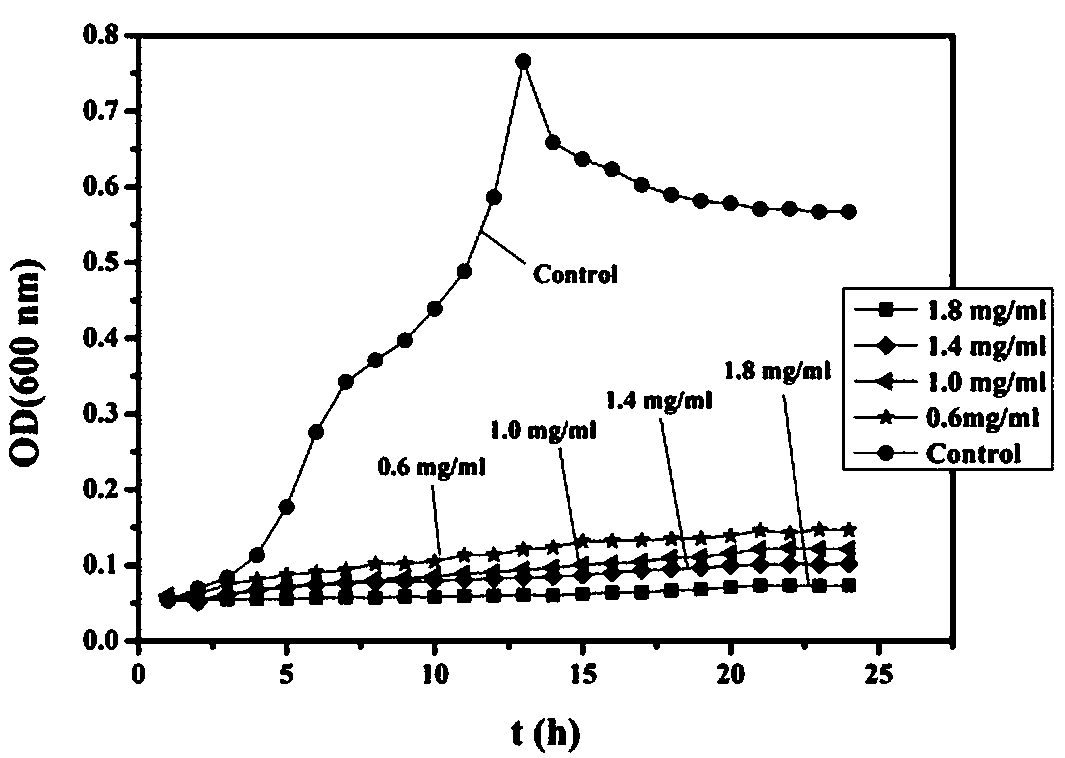

[0025] A preparation method of ZnO / GQD-PEI composite quantum dot antibacterial agent, comprising the following steps:

[0026] Step 1: Preparation of graphene quantum dots (GQDs) solution:

[0027] Put 1-10g of citric acid (CA) into a beaker and heat to obtain an orange liquid; then, add sodium hydroxide solution dropwise to adjust the pH=7.0, dialyze and rotary evaporate to obtain a graphene quantum dot (GQDs) solution ;

[0028] Step 2: Preparation of GQD-PEI:

[0029] Dilute the GQDs obtained in step 1 to 0.2-2mg / ml with deionized water, add a modifier to make the concentration 5-15mg / ml, and after ultrasonic treatment for 10min, add 0.05-0.2g 1-ethyl-(3- Dimethylaminopropyl) carbodiimide hydrochloride (EDC•HCl), ultrasonic treatment for 20min, then add 0.2-0.5g EDC•HCl, ultrasonic treatment for 20min, magnetic stirring at room temperature for 24h, to obtain GQD-PEI;

[0030] Step 3: Preparation of modified ZnO / GQD-PEI composite quantum dot antibacterial agent:

[0031]...

Embodiment 1

[0039] Step 1: Put 2g of citric acid (CA) into a 50ml beaker, heat to 200°C and react for 30 minutes to obtain an orange liquid; then, adjust the pH to 7.0 with aqueous sodium hydroxide solution, dialyze for 24 hours, and rotate to evaporate to obtain the GQDs solution;

[0040] Step 2: Dilute the GQDs obtained in step 1 to 0.5 mg / ml with deionized water, add polyethyleneimine (PEI) to make the concentration 8 mg / ml, and after ultrasonic treatment for 10 min, add 0.1 g 1-ethyl-( 3-Dimethylaminopropyl) carbodiimide hydrochloride (EDC•HCl), ultrasonic treatment for 20min, then add 0.3g EDC•HCl, ultrasonic treatment for 20min, magnetic stirring at room temperature for 24h, to obtain GQD-PEI ;

[0041] Step 3: Add 0.3 g of potassium hydroxide to 50 ml of ethanol solution, and stir magnetically for 30 minutes to obtain solution A; add 0.587 g of zinc acetate dihydrate to 100 ml of ethanol solution, and stir magnetically for 30 minutes to obtain solution B; Add the GQD-PEI obtained...

Embodiment 2

[0043] Step 1: Put 4g of citric acid (CA) into a 50ml beaker, heat to 200°C and react for 30 minutes to obtain an orange liquid; then, adjust the pH to 7.0 with aqueous sodium hydroxide solution, dialyze for 24 hours, and rotate to evaporate to obtain the GQDs solution;

[0044] Step 2: Dilute the GQDs obtained in Step 1 to 1 mg / ml with deionized water, add polyethyleneimine (PEI) to make the concentration 10 mg / ml, and after ultrasonic treatment for 10 min, add 0.12 g of 1-ethyl-(3 - Dimethylaminopropyl) carbodiimide hydrochloride (EDC·HCl), after ultrasonic treatment for 20 minutes, then add 0.388g EDC·HCl, ultrasonic treatment for 20 minutes, magnetic stirring at room temperature for 24 hours, to obtain GQD-PEI;

[0045] Step 3: Add 0.42g of sodium hydroxide to 50ml of ethanol solution, and stir magnetically for 30min to obtain solution A; add 0.78g of zinc acetate dihydrate to 100ml of ethanol solution, and stir magnetically for 30min to obtain solution B; Add the GQD-PEI ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com