A processing technology of high crimp silky cut stems

A technology of processing technology and curling degree, which is applied in the field of processing technology of high-curling shredded stems, can solve the problems of poor adaptability of conventional tobacco stems, high cost and difficulty of technical transformation, cumbersome production process, etc., to ensure integrity and Uniformity, low cost of technological transformation, and the effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

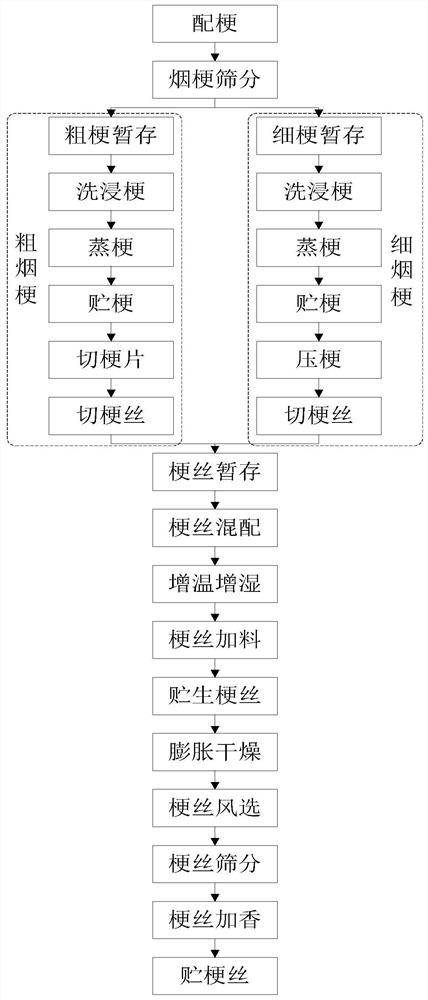

[0025] Example 1: Preparation of high-crimp filamentous cut stems

[0026] Blending stems: the Sichuan flue-cured tobacco stems and Henan flue-cured tobacco stems produced in 2017 were evenly blended at a mass ratio of 60%:40%;

[0027] Tobacco stem screening: Screen the mixed tobacco stem raw materials, using a long-hole drum tobacco stem screening machine with a pore size of 4.5mm, and divide the tobacco stems into thin tobacco stems with a diameter of <4.5mm and thick tobacco stems with a diameter of ≥4.5mm. Tobacco stems.

[0028] Temporary storage of tobacco stems: the sieved thin tobacco stems and thick tobacco stems are stored in different temporary storage cabinets.

[0029] Thin tobacco stem processing: the temporarily stored thin tobacco stems are washed and soaked, steamed, stored, pressed, shredded, and temporarily stored. The purpose of washing and soaking stems is to increase the moisture content of the tobacco stems and remove dust on the surface of the tobacc...

Embodiment 2

[0033] Example 2: Preparation of high-crimp shredded stems

[0034] Blending stems: The Sichuan flue-cured tobacco stems and Yunnan flue-cured tobacco stems produced in 2017 were evenly blended at a mass ratio of 30%:70%.

[0035] Tobacco stem screening: Screen the mixed tobacco stem raw materials, using a long-hole drum tobacco stem screening machine with a pore size of 4.5mm, and divide the tobacco stems into thin tobacco stems with a diameter of <4.5mm and thick tobacco stems with a diameter of ≥4.5mm. Tobacco stems.

[0036] Temporary storage of tobacco stems: the sieved thin tobacco stems and thick tobacco stems are stored in different temporary storage cabinets.

[0037] Thin tobacco stem processing: the temporarily stored thin tobacco stems are washed and soaked, steamed, stored, pressed, shredded, and temporarily stored. The purpose of washing and soaking stems is to increase the moisture content of the tobacco stems and remove dust on the surface of the tobacco stem...

Embodiment 3

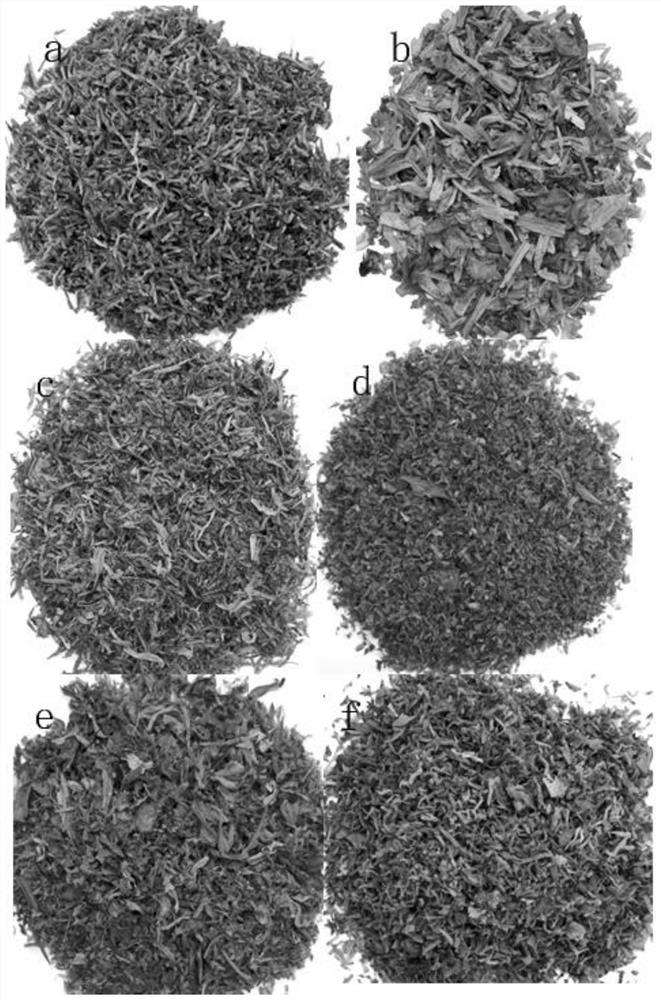

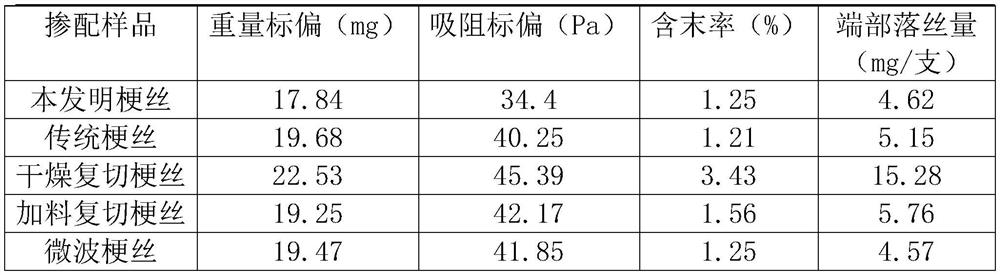

[0041] Embodiment 3 The comparative analysis of cut stem physical index

[0042] Materials: shredded leaves of a certain brand, shredded stems obtained by 5 kinds of processing methods.

[0043] Instruments: CWT200 leaf shape measuring instrument (Zhengzhou Tobacco Research Institute), YGD450 filling value measuring instrument (Zhengzhou Jiade Electromechanical Technology Co., Ltd.), YQ-2 leaf silk vibrating sorting screen (Zhengzhou Tobacco Research Institute).

[0044] Sample Preparation:

[0045] Under the existing technological conditions, the samples were prepared as many times as possible through the reduction of different shredded stems.

[0046] Method 1, using the process of the present invention to prepare shredded stems, see Example 1 for details.

[0047] Method 2, traditional shredded stem preparation steps: blending stems, sieving tobacco stems (removing stems and thin stems <2.5mm), washing and soaking stems, steaming stems once, storing stems, steaming stems tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com