A gelable system for lithium-air batteries and its preparation method and application

A lithium-air battery and gelation technology, which is applied to fuel cell-type half-cells and secondary battery-type half-cells, etc., can solve the problems of liquid electrolyte leakage, non-reuse, and easily damaged gel state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

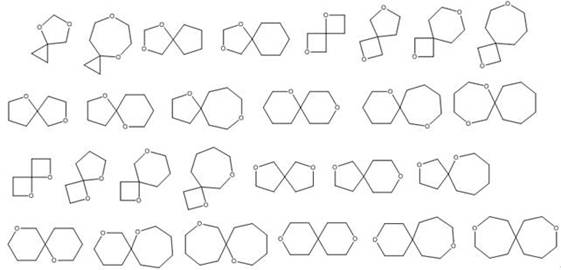

Method used

Image

Examples

preparation example Construction

[0148] Preparation of graphene air electrode: Weigh mass ratio of 9: graphene and polyvinylidene fluoride (PVDF). 1, the amount of added dropwise N- methylpyrrolidone (NMP) to PVDF, the ultrasonic oscillation for 1 hour, to this solution was poured into a mortar, adding the graphene about milled for 1 hour, and then the mixed slurry was coated on a certain area of the carbon paper, and dried in vacuo at 100 deg.] C after 48 hours, cut with a microtome the desired size;

[0149] The negative electrode is a lithium sheet;

[0150] Electrolyte: a solid electrolyte or a gel electrolyte prepared in the respective embodiments;

[0151] Diaphragm: Whatman membrane.

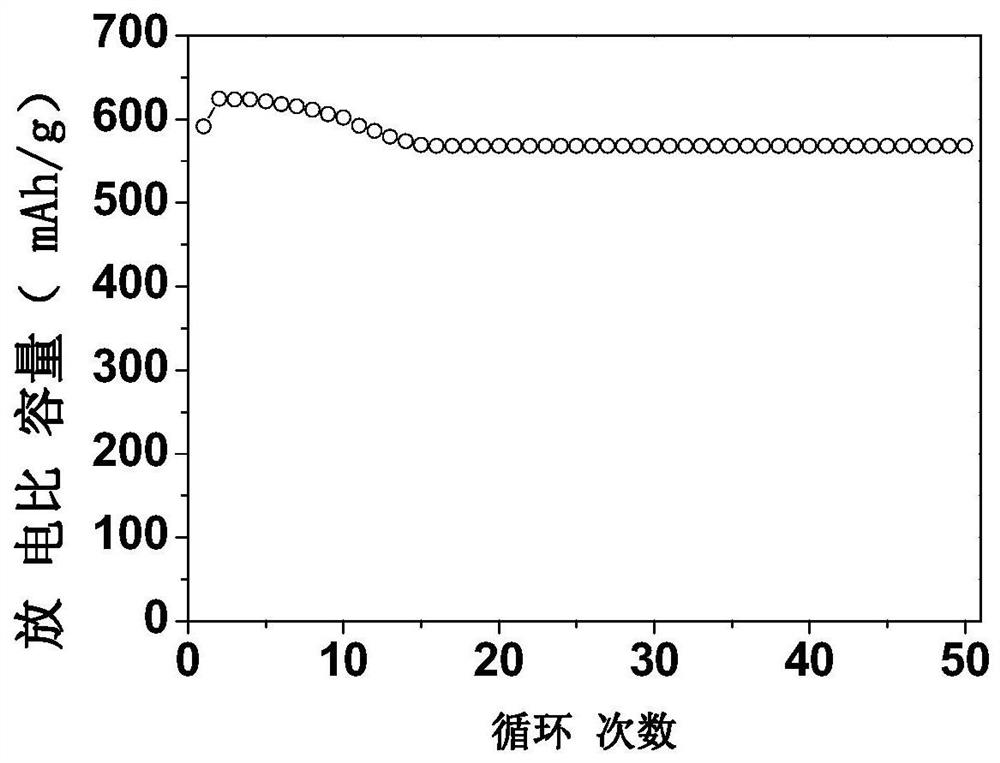

Embodiment 1

[0153] Preparation of (1) gelling system and a gel (a gel electrolyte cell may be used) of

[0154] Weigh 0.8g of lithium hexafluorophosphate in the reagent bottle, a mixture of 2.0mL of dimethyl carbonate and ethylene carbonate was added thereto (wherein dimethyl carbonate: ethylene carbonate = 1: 1 (v / v)), so that the stirring lithium salt is completely dissolved, 2.0mL1,4- 2mL1,3- dioxane and dioxolane the mixture was added the lithium salt solution, and after stirring sufficiently mixed to obtain gelable system; a period of inactivity, forming condensate glue.

[0155] The gel system, the mass percentage of lithium salt is 12wt%; mass percentage of an ether compound is 58wt%; mass percentage of the electrolyte solution for a lithium-air battery or a solvent is 30wt%.

[0156] After testing, the performance parameters of the gel are shown in Table 1.

[0157] When the prepared gel is heated above the transition temperature of the gel, the gel starts to become tacky, the gel w...

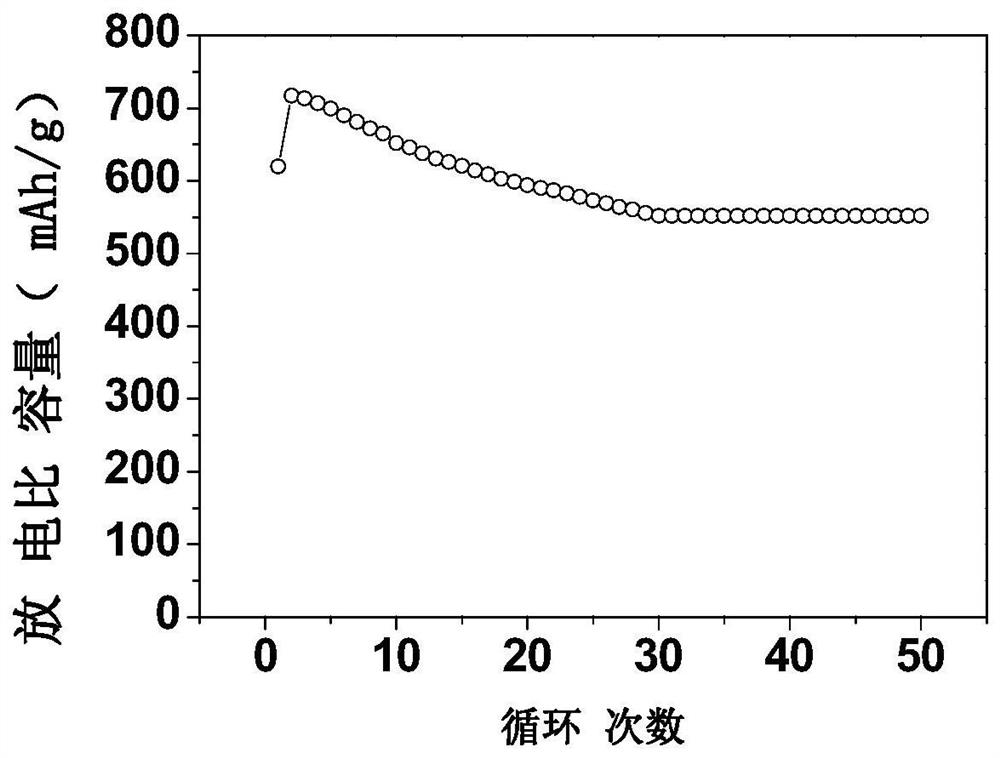

Embodiment 2

[0161] (1) Preparation of a gelatable system and solid electrolyte

[0162] Weigh 0.5g of lithium perchlorate, lithium hexafluorophosphate and 1.0 g of bis 0.2g of lithium trifluoromethane sulfonimide in the reagent bottle, to which was added 3.0mL of tetraglyme, under magnetic stirring, lithium salt is completely dissolved, 8.0mL tetrahydropyranyl, mixed well, to give gelable system; standing for some time, to form a solid electrolyte.

[0163] The solid electrolyte system, the mass percentage of lithium salt is 15wt%; mass percentage of an ether compound is 68wt%; mass percentage of the electrolyte solution for a lithium-air battery or a solvent is 17wt%.

[0164] After testing, the performance parameters of the solid electrolyte is shown in Table 1.

[0165] When the prepared solid electrolyte is heated above the transition temperature of the solid electrolyte, the solid electrolyte begins to stick, the solid electrolyte may be observed to flow downward reagent bottle upside do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com