Concentration management device of development liquid and development processing system of base plate

A technology of management device and processing system, applied in photography, photoengraving process of pattern surface, optics, etc., can solve problems such as difficulty in earning profits, and achieve the effect of high-precision concentration management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

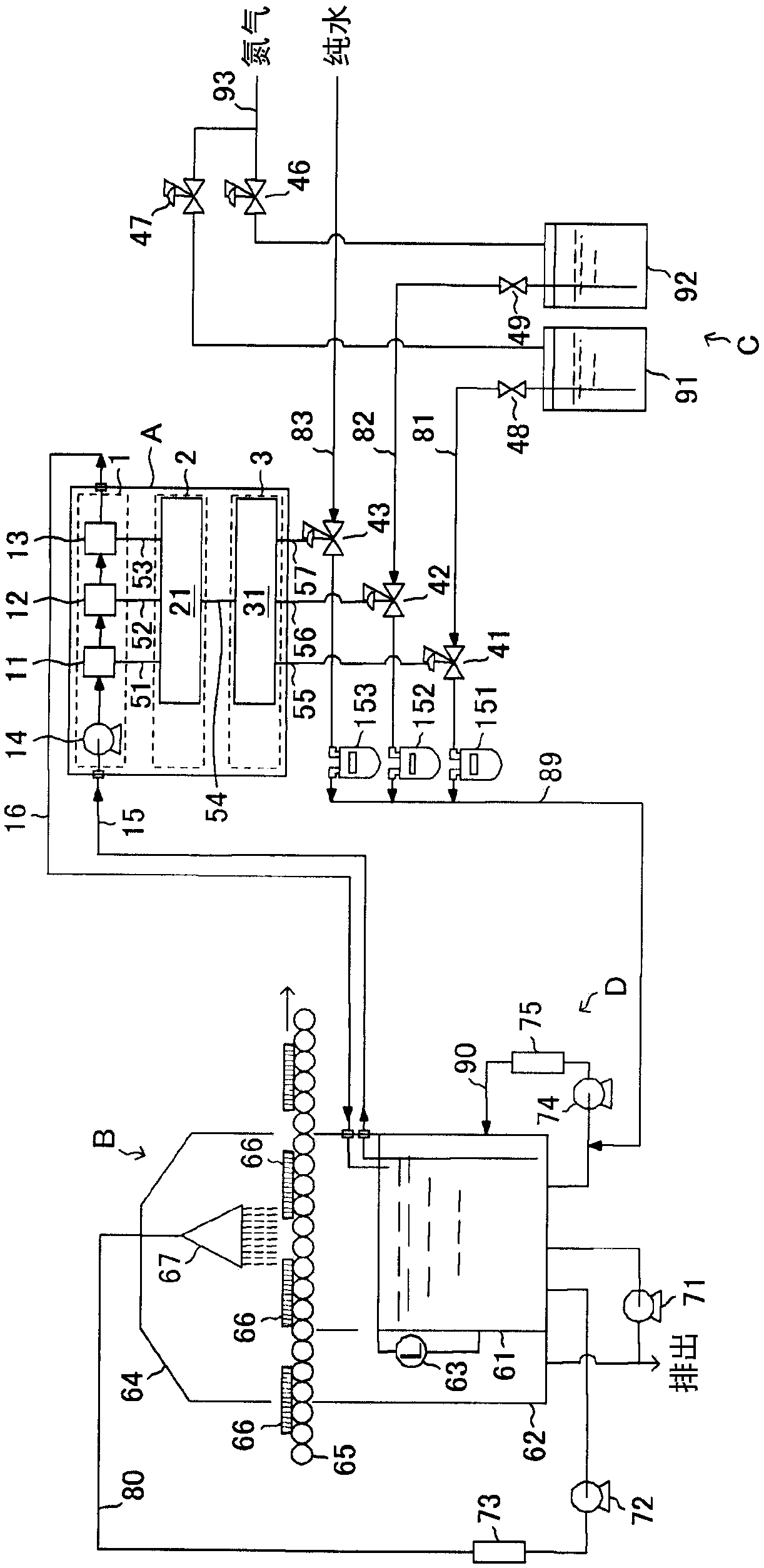

[0108] figure 1 It is a schematic diagram for demonstrating the development processing system of the board|substrate equipped with the concentration management apparatus A of the developer of this embodiment.

[0109] During the development process, the developing solution dissolves unnecessary portions of the photoresist film after the exposure treatment, thereby performing development. A photoresist salt is generated between the photoresist dissolved in the developer and the alkali component of the developer. Therefore, if the developing solution is not properly managed, as the development process progresses, the alkali component having development activity in the developing solution is consumed and deteriorates, and the developing performance deteriorates. At the same time, the photoresist dissolved in the developer reacts with the alkali component and accumulates in the form of photoresist salt.

[0110] The photoresist dissolved in the developer exhibits interfacial act...

no. 2 approach 〕

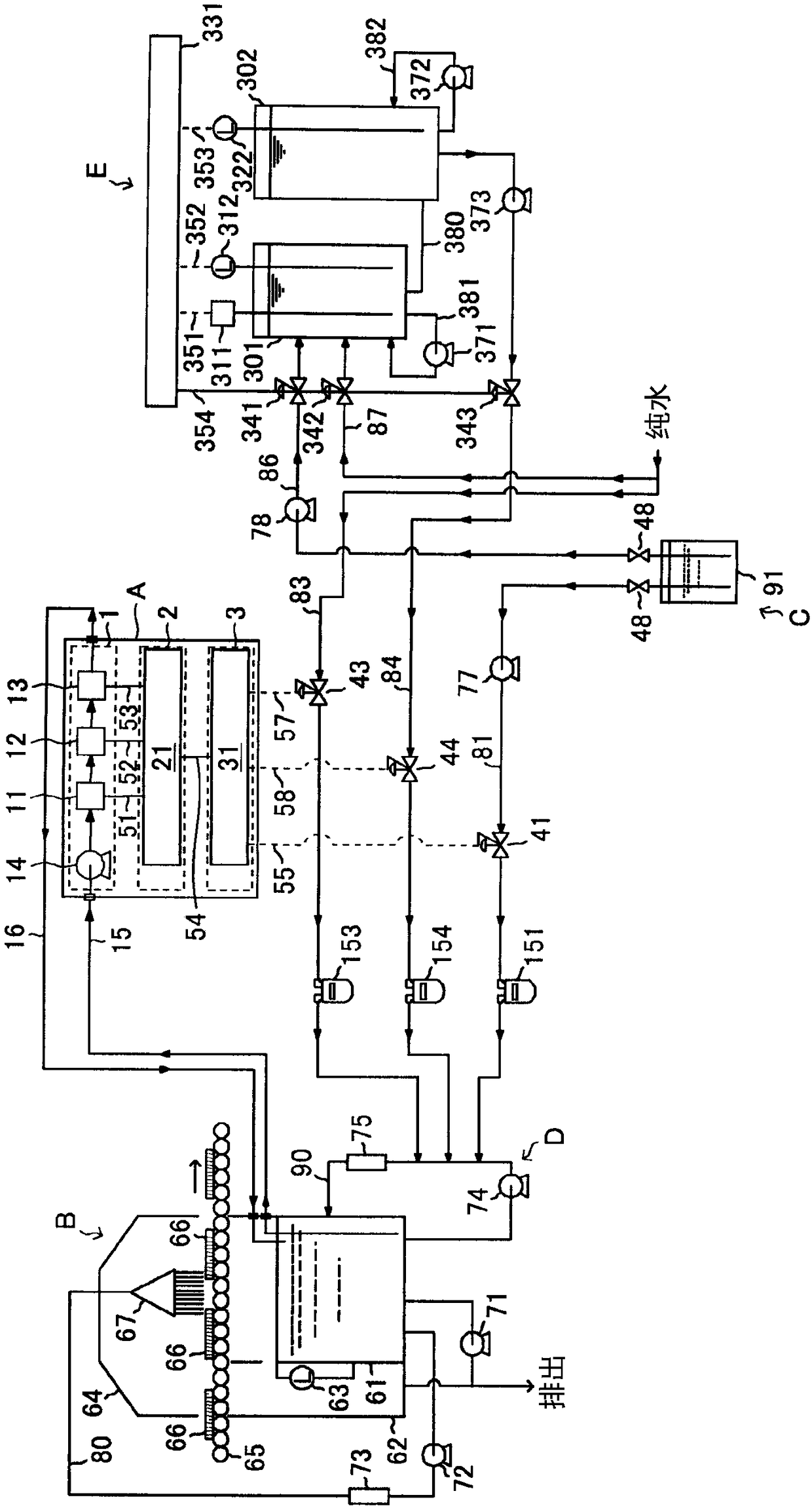

[0176] figure 2 It is a schematic diagram for explaining the development processing system of the board|substrate. The development processing system for this substrate includes: the developer concentration management device A, the development processing device B, and the preparation device E according to this embodiment; B: A pipe 83 for supplying pure water; a pipe 84 for new liquid that supplies a new liquid of the developer prepared by the preparation device E to the developing processing device B; and a control valve 41 arranged in these pipes and controlled by the concentration management device A , 43, 44 and cumulative flow meters 151, 153, 154.

[0177] exist figure 2 In the above, the new liquid of the developer supplied as the replenisher is automatically prepared and supplied by the preparation device E using the original liquid of the developer and pure water as its raw materials. The preparation device E is connected to the development processing device B via...

no. 3 approach 〕

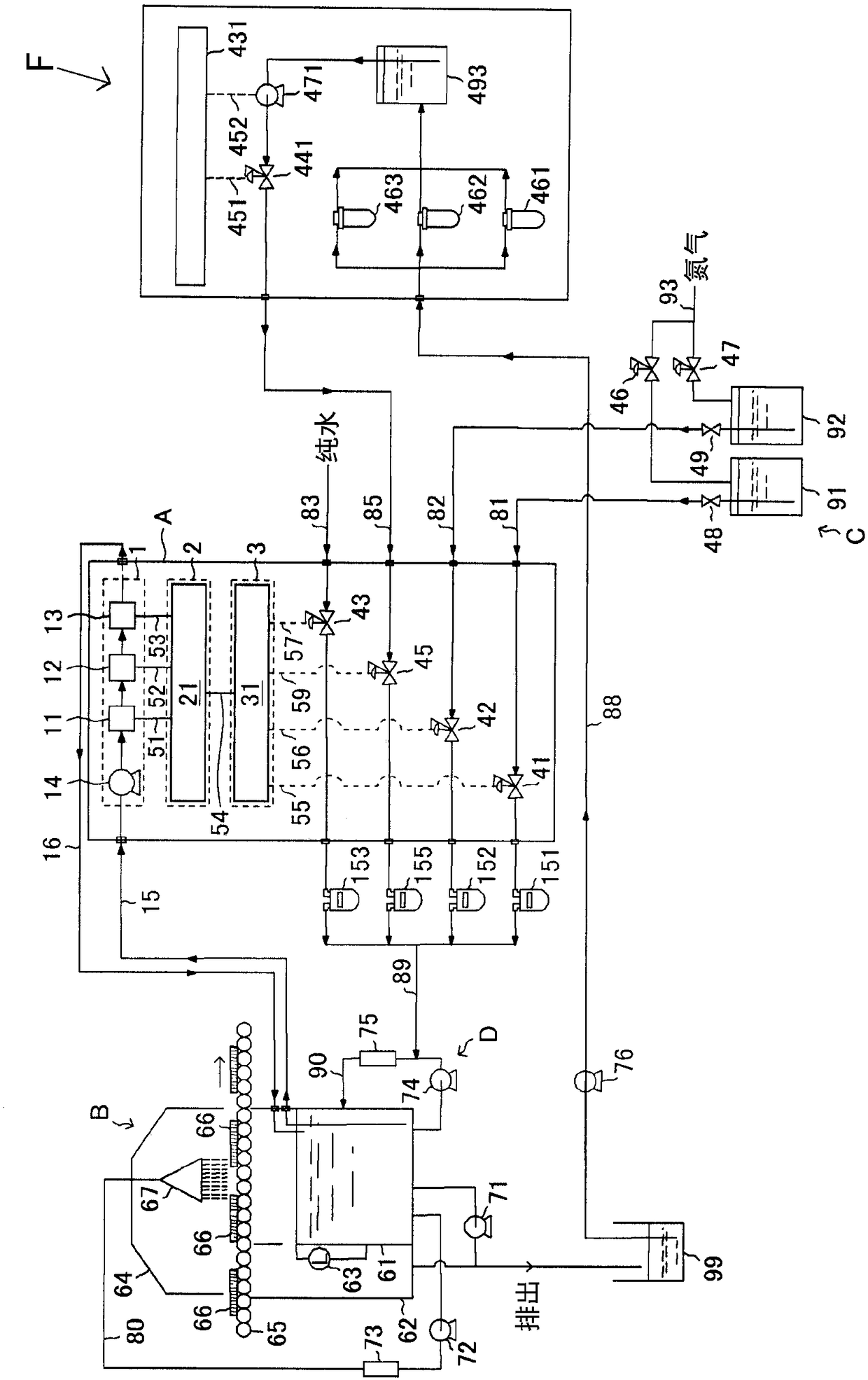

[0193] image 3 It is a schematic diagram for explaining the development processing system of the board|substrate provided with the density management apparatus A of a developer, the development processing apparatus B, the regeneration apparatus F, and the integrated flow meter 151, 152, 153, 155 of this embodiment.

[0194] exist image 3 In , the developer used in the development processing device B is regenerated by the regenerating device F so that it can be reused. The regenerating liquid regenerated by the regenerating device F is supplied to the developing processing device B as one of replenishing liquids. The regeneration device F is connected to the development processing device B through a regeneration liquid pipe 85 . The piping 85 for regeneration liquid is provided with the control valve 45 and the integrated flow meter 155 .

[0195] in addition, image 3 The developing solution concentration management device A is in a form including control valves 41 , 42 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com