Wet and cold steam turbine generator unit lubricating oil heat recovery and utilization method

A technology for steam turbine generator set and heat recovery, applied in the field of lubricating oil system, can solve the problems of increasing the maintenance workload of the unit, easy scaling of the oil cooler, and unrecovered heat of the lubricating oil return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

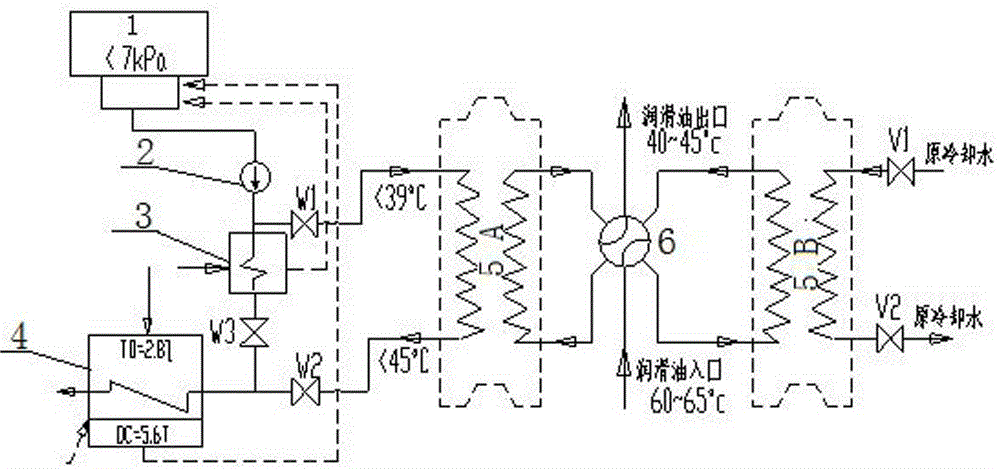

[0010] see figure 1 , The circulating lubricating oil system is usually equipped with two oil coolers 5 (5A, 5B), one for use and one for standby, switched by switching valve 6, and one of them is used.

[0011] The oil cooler 5B on the right is an unmodified cooling oil system. The oil return temperature of lubricating oil is usually 60-65°C, and it is cooled to 40-45°C by circulating cooling water. The conventional water demand is about 300~1000t / h.

[0012] The oil cooler 5A on the left is a modified cooling oil system, including a wet condenser 1, a condensate pump 2, a steam seal heater 3, and a low-pressure heater 4 at the end. The implementation is: a branch is drawn from the outlet of the condensate pump 2, and part or all of the condensate in the wet condenser 1 is introduced into the oil cooler 5A to replace the conventional circulating cooling water. The temperature of the condensate is usually controlled at 39°C Next, adjust the flow rate of the condensed water by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com