Chemical liquid management system and expense computing method and system for substrate processing device

The technology of a substrate processing device and a management system is applied to the liquid medicine management system of the substrate processing device, the cost calculation and the system field, and can solve the problems of difficulty in earning profits and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

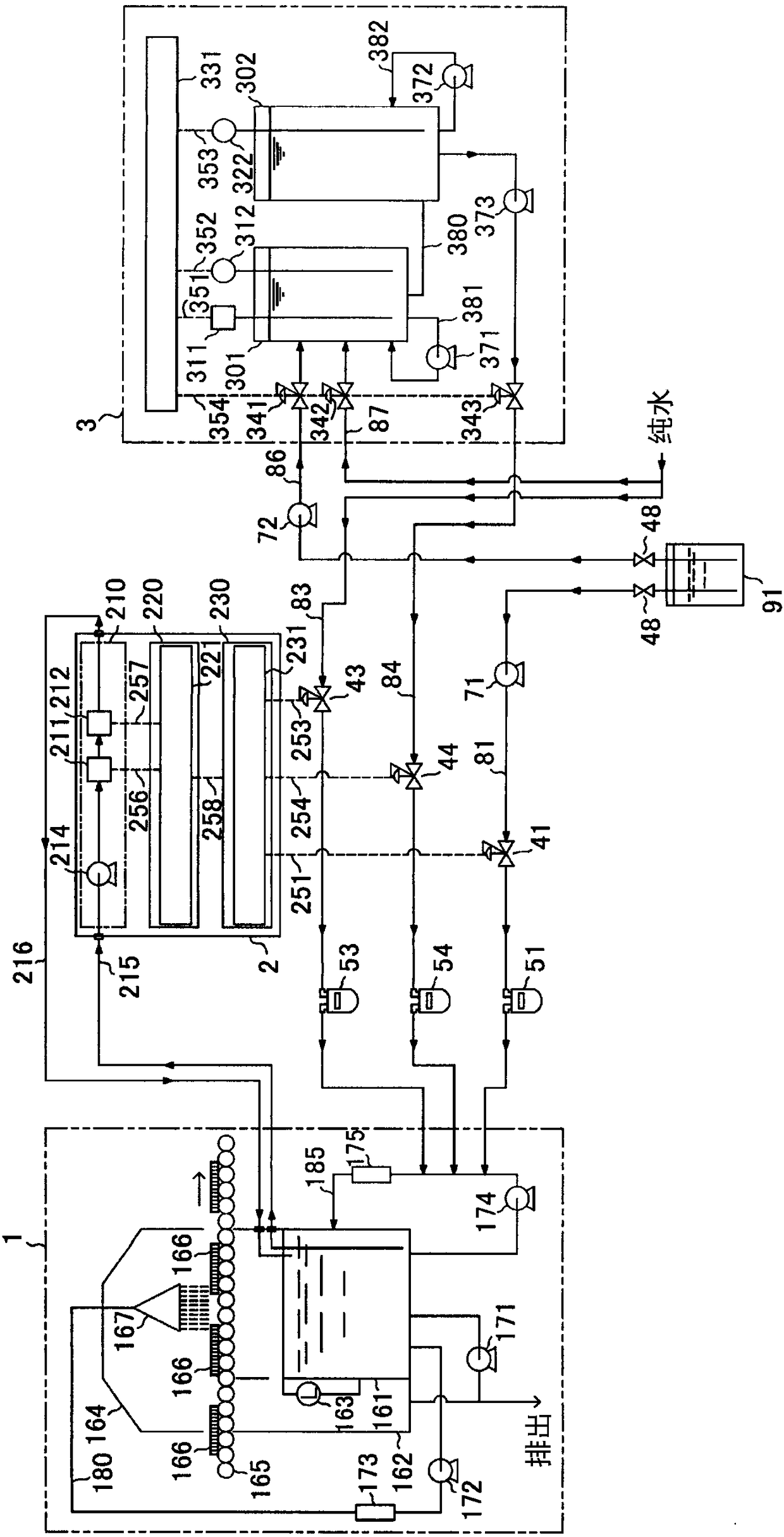

[0108] figure 1 It is a schematic diagram for explaining a chemical solution management system of a substrate processing apparatus including a chemical solution preparation device, a concentration management device, and an integrated flow meter according to the present embodiment. In the description of this embodiment, the following chemical solution management will be described: taking a 2.38% concentration of TMAH aqueous solution (developing solution) as an example as a chemical solution, and replenishing it with a 20% TMAH aqueous solution (developing solution) as a replenishing liquid. Stock solution), unused 2.38% TMAH aqueous solution (new solution of developer solution) and pure water for concentration management.

[0109] exist figure 1In this method, using the developer solution preparation device 3 as an example of the chemical solution preparation device, the new developer solution is automatically prepared and supplied from the stock solution of the chemical solu...

no. 2 approach 〕

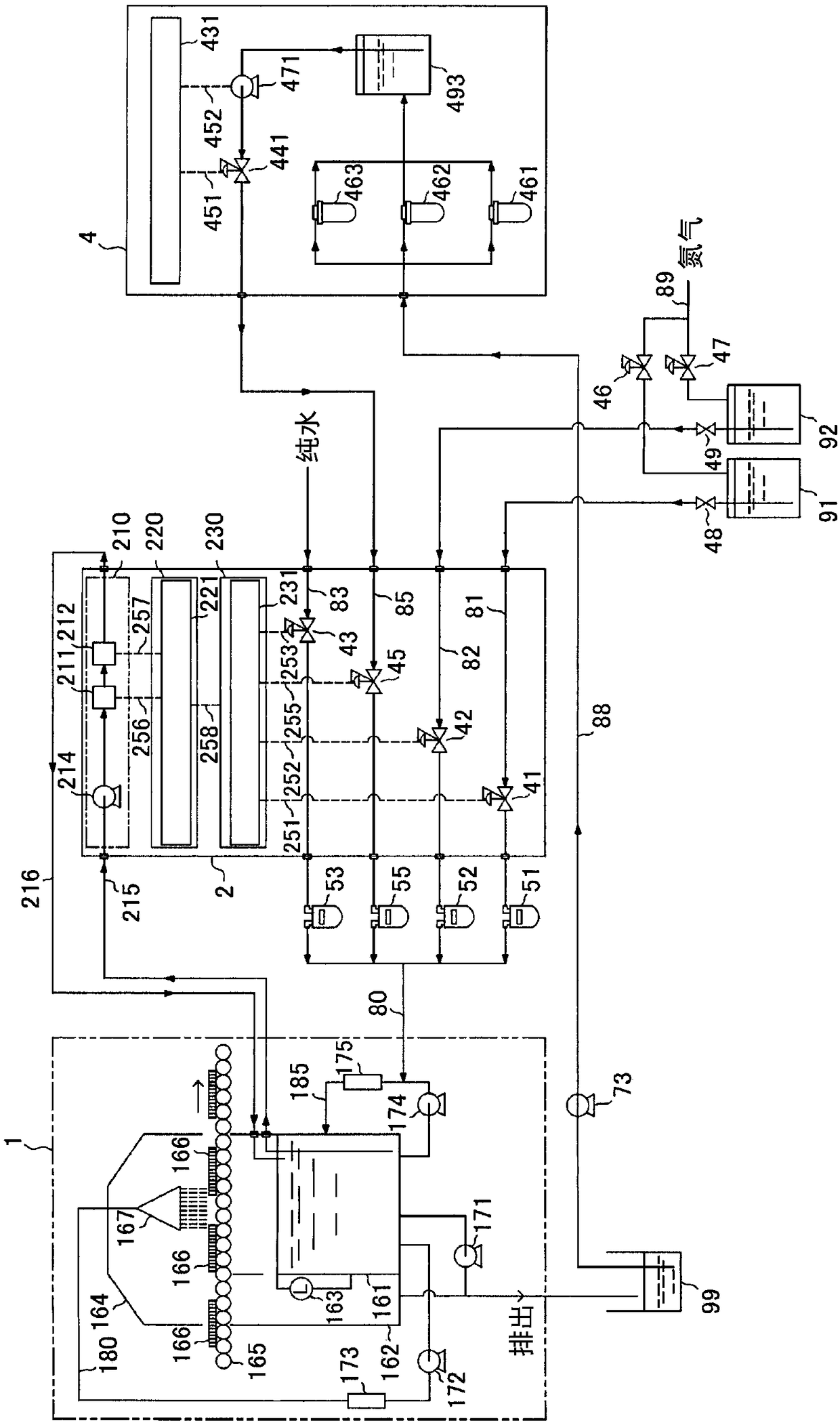

[0147] figure 2 It is a schematic diagram for explaining a chemical solution management system of a substrate processing apparatus including a chemical solution regeneration device, a concentration management device, and an integrated flow meter according to the present embodiment.

[0148] exist figure 2 In this process, the chemical solution used in the development process facility 1 which is an example of a substrate processing apparatus is regenerated so that it can be reused by the developer solution regeneration device 4 which is an example of a chemical solution regeneration device. The regenerated developer that is regenerated by the developer regenerating device 4 is supplied to the developing process equipment 1 as one of the replenishing liquids. The developing solution regenerating device 4 is connected to the developing process equipment 1 via a piping 85 as a piping for regenerating liquid.

[0149] In addition, as figure 2 In the developer solution managem...

no. 3 approach 〕

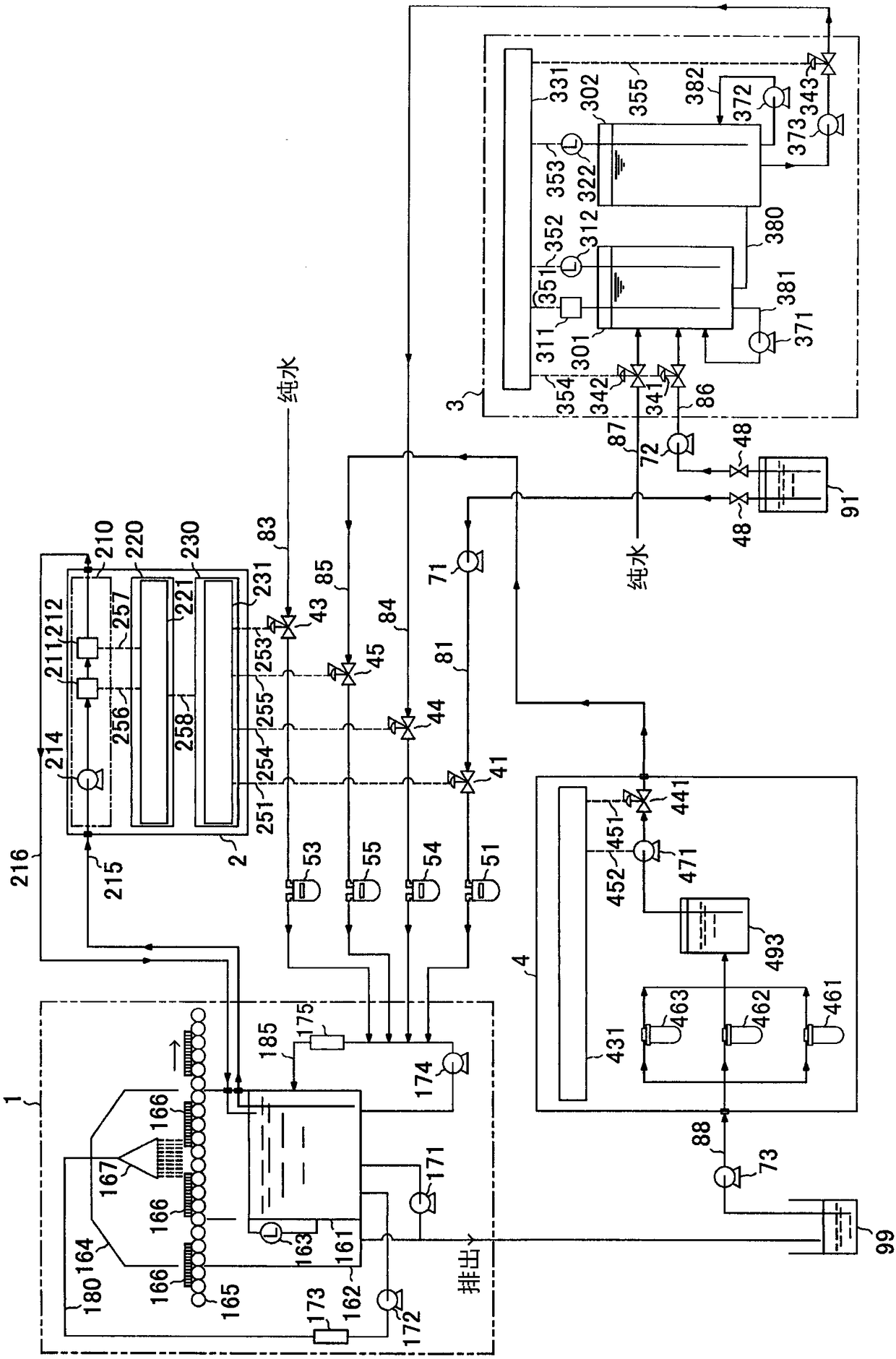

[0166] image 3 It is a schematic diagram for explaining a chemical solution management system of a substrate processing device including a concentration management device, a chemical solution preparation device, a chemical solution regeneration device, and an integrated flow meter according to the present embodiment.

[0167] In this embodiment is in figure 1 In the chemical solution management system of the substrate processing apparatus of the first embodiment shown, the figure 2 The developer solution regenerating device 4 as an example of the chemical solution regenerating device described in the second embodiment shown is formed. The development process equipment 1 , the developer solution management device 2 , the developer solution preparation device 3 , and other components of this embodiment are the same as those of the first and second embodiments, and thus redundant description thereof will be omitted.

[0168] image 3 The chemical solution management system o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com