Device and method for measuring heat exchange characteristics of high-temperature molten salt in micro-channel

A high-temperature molten salt and micro-channel technology, which is used in the measurement of heat transfer characteristics of high-temperature molten salt in micro-channels, and the field of measuring devices for heat-transfer characteristics of high-temperature molten salt in micro-channels, which can solve the problem of high cost and large molten salt test platform system. , low operation reliability and other problems, to achieve the effect of low cost, easy operation and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

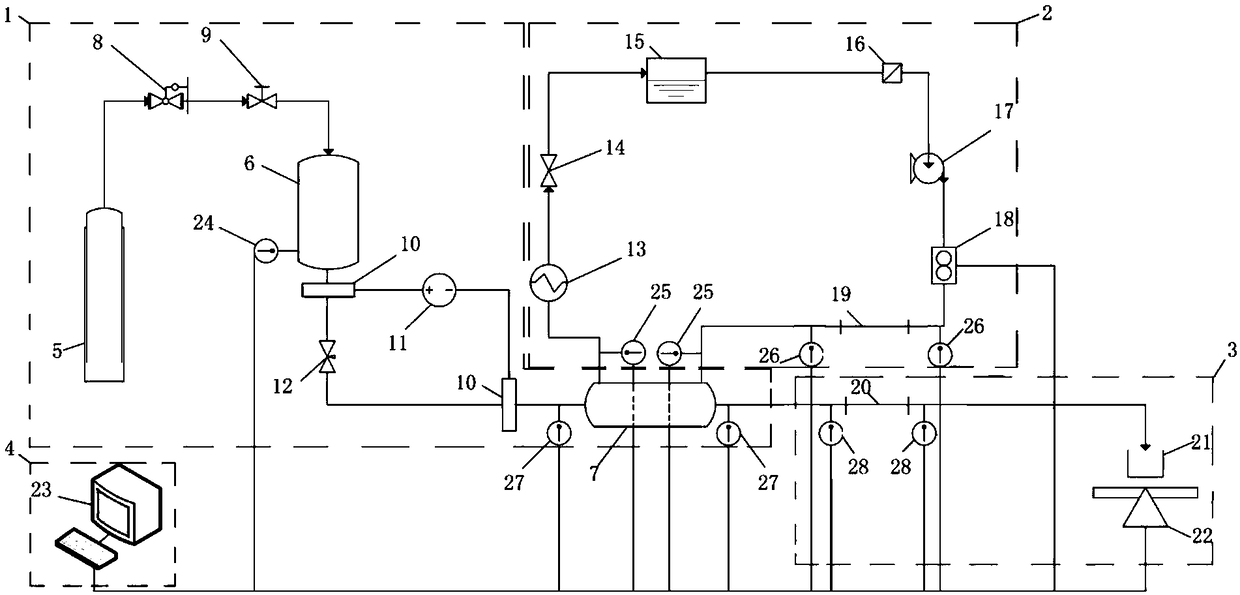

[0025] The present invention is a measuring device for the heat transfer characteristics of high-temperature molten salt in a tiny channel, such as figure 1 As shown, it includes high-temperature molten salt heating pipe section 1, water circulation pipe section 2, and test and product collection pipe section 3, which are connected in sequence through pipelines. Insulation cotton, high-temperature molten salt heating pipe section 1, water circulation pipe section 2, and test and product collection pipe section 3 are connected to the data acquisition and display module 4 through wires.

[0026] Such as figure 1 As shown, the high-temperature molten salt heating pipe section 1 includes a nitrogen tank 5, and the nitrogen tank 5 is sequentially connected to the molten salt tank 6 and the brine heat exchanger 7 through pipelines, and the pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com