Device for connecting with threaded fastener

A technology for threaded fasteners and equipment, applied in the field of equipment for connecting threaded fasteners, can solve the problems of scrapping threaded fasteners, affecting the detection results of threaded fasteners, etc., and achieve the effect of a clean and tidy outer surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

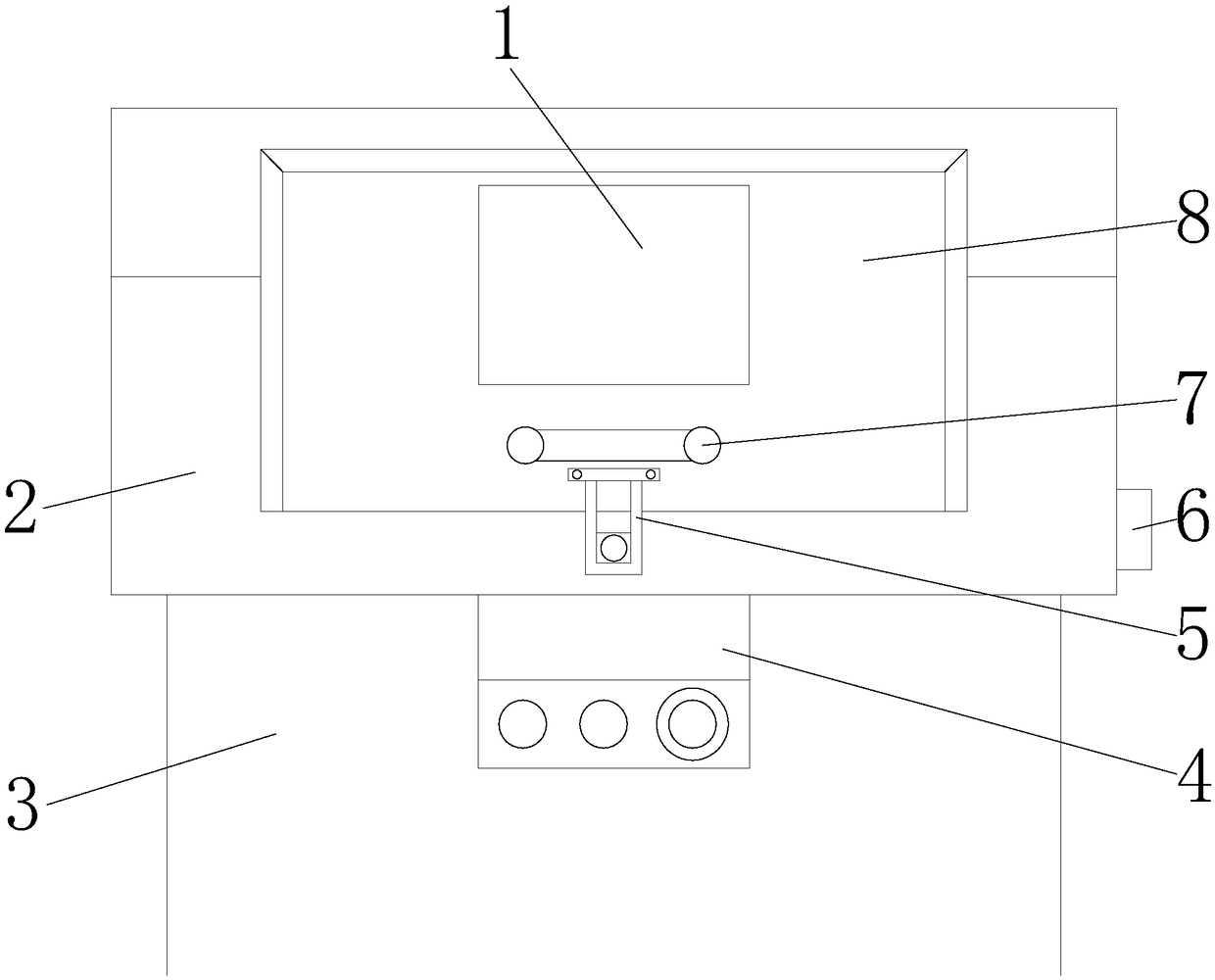

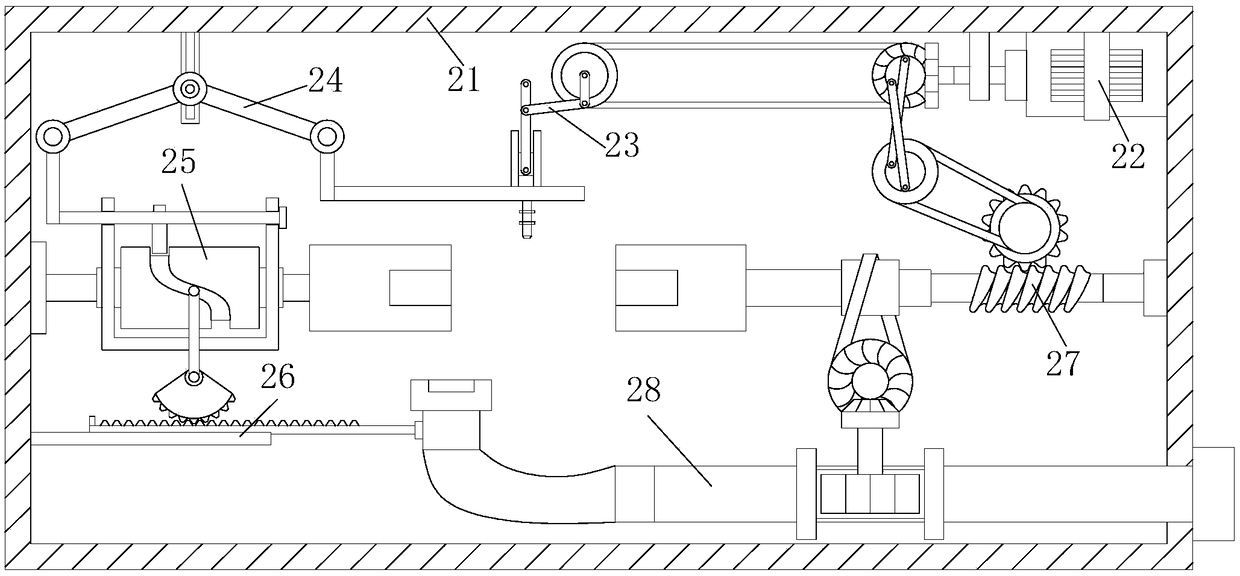

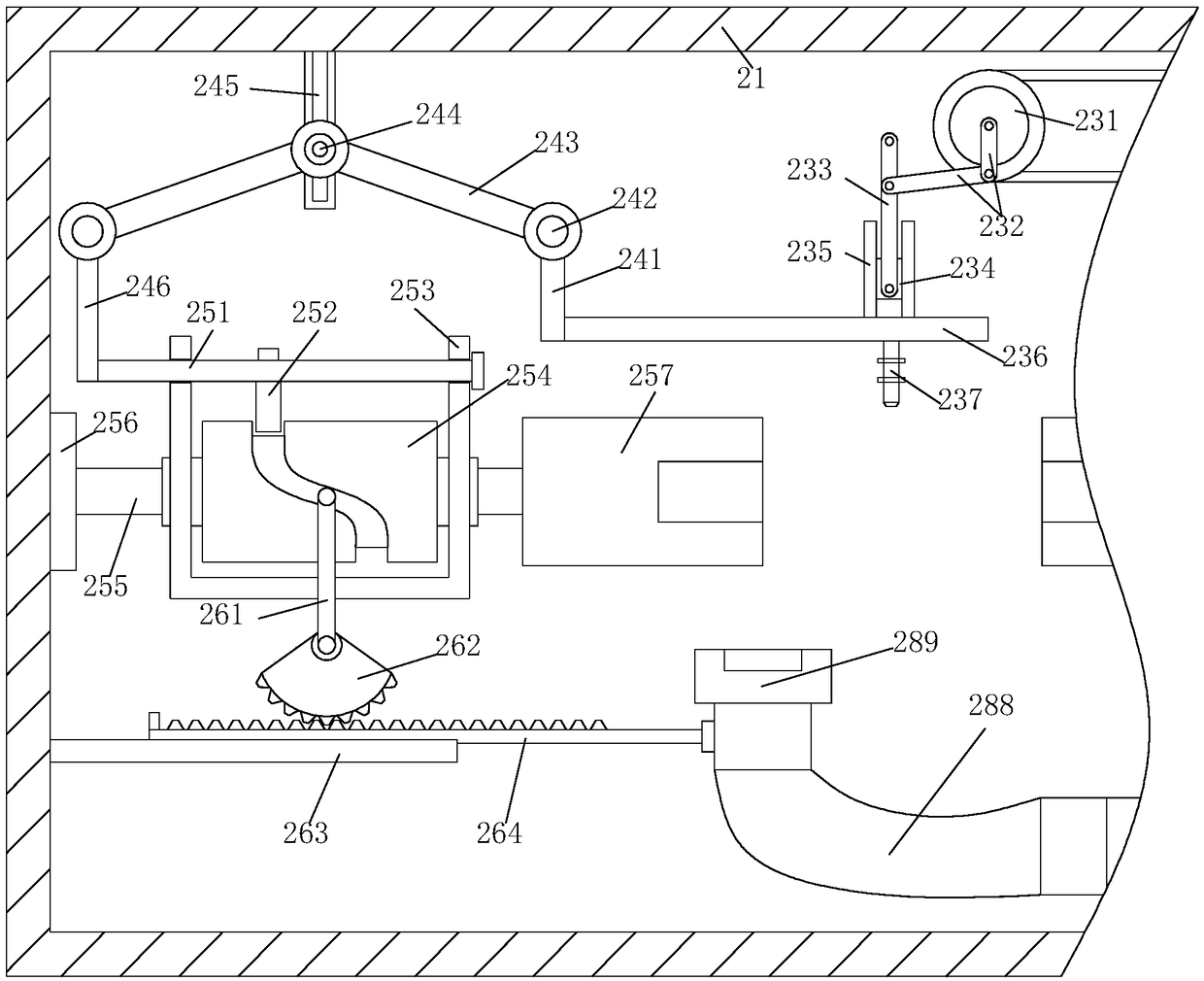

[0024] see Figure 1-Figure 4, the present invention provides equipment for connecting threaded fasteners, the structure of which includes a window 1, a detection host 2, a base 3, an operation panel 4, buckles 5, an air inlet 6, a handle 7, and a case cover 8. The window 1 Embedded in the front surface of the box cover 8, the box cover 8 is embedded in the front surface of the detection host 2, the lower surface of the detection host 2 is welded to the upper surface of the base 3, and the operation panel 4 is fixedly installed in the middle of the upper end of the front surface of the base 3 And it is electrically connected with the detection host 2 through wires, the upper end of the buckle 5 is hinged with the lower end of the front surface of the case cover 8, the lower end of the buckle 5 is connected with the middle part of the lower end of the front surface of the detection host 2, and the air inlet 6 is embedded Installed on the right side surface of the detection host...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com