Grouting and water blocking method for large inclined angle vertical fracture formation

A technology of large inclination and grouting, which is used in vertical shaft equipment, earth-moving drilling, mining equipment, etc., can solve the problems of grouting final pressure reaching 12Mpa, failing to achieve the expected effect and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

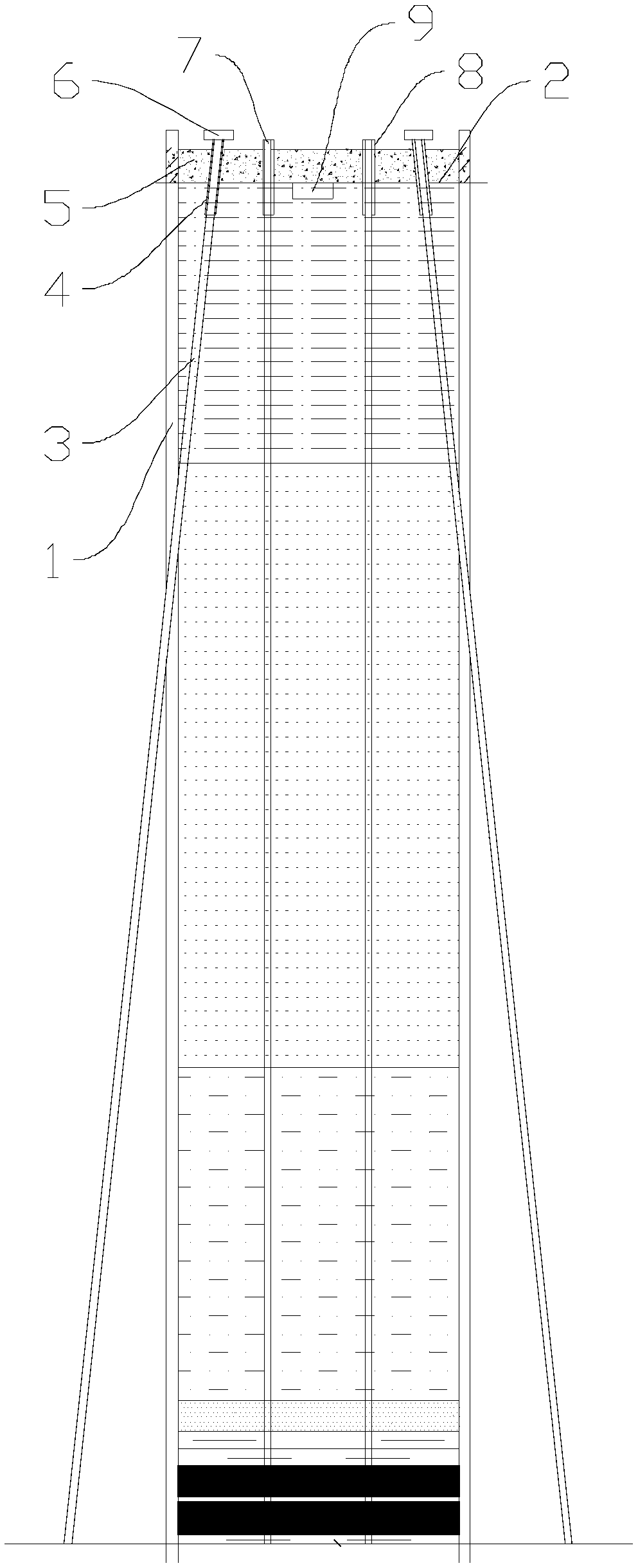

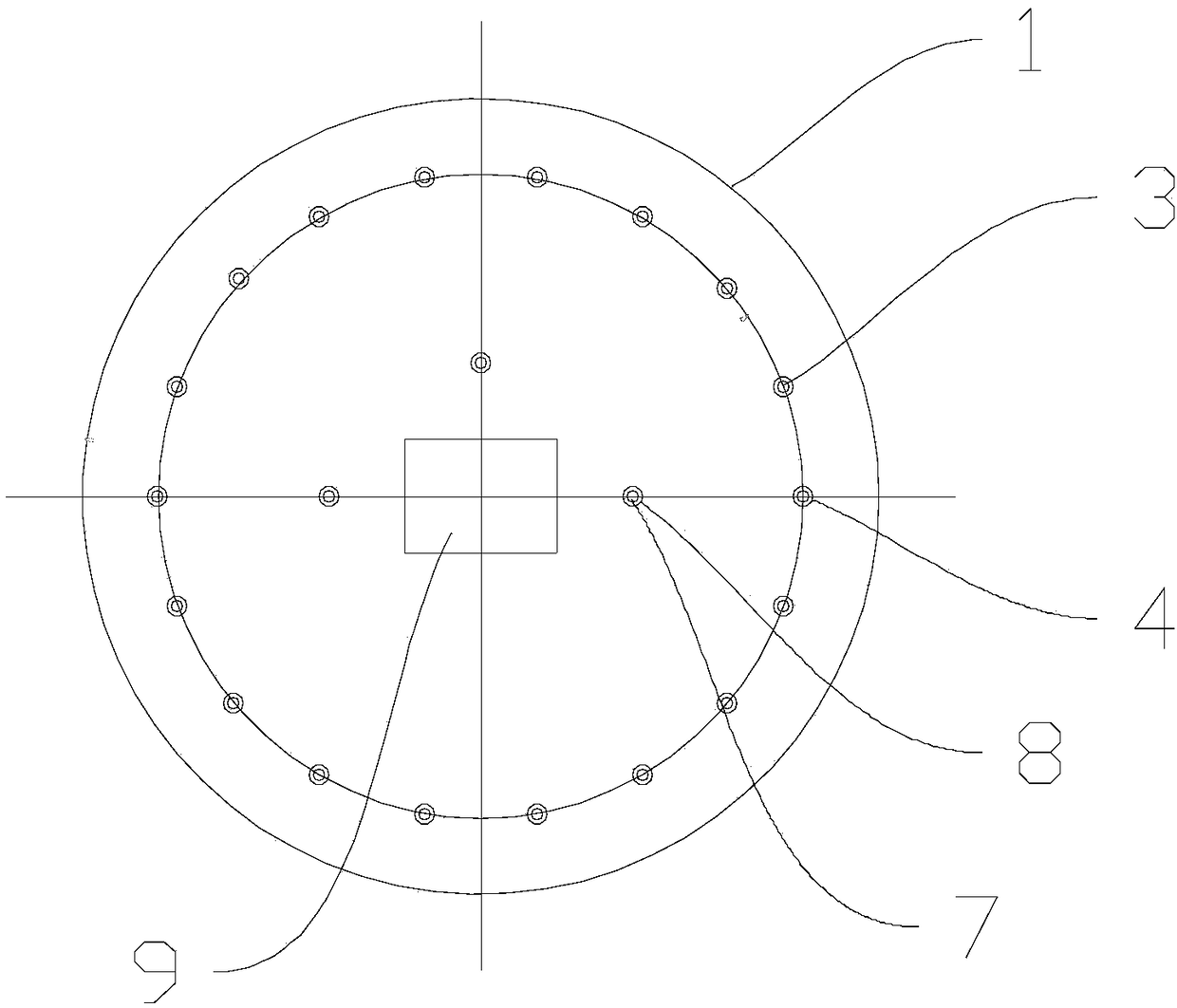

[0110] The designed depth of the auxiliary vertical shaft of Tangjiahui Coal Mine is 544.8m, the net diameter of the shaft is 10.5m, and the section is circular.

[0111] 1. Definition of the working face: adopt comprehensive mechanized supporting excavation and masonry construction, expose vertical cracks with a large dip angle near the depth of 440m, the inclination angle is 60°, the shaft is excavated to 447.0m, 1.5m down and brush the sides, 448.5m The position is defined as working surface 2.

[0112] 2. Construction grout stop pad:

[0113] 2.1. Lifting the formwork: Lower the formwork to the working surface 2 and remove the bottom edge of the formwork, and then lift the formwork to a position 3.5m away from the working surface 2.

[0114] 2.2. Cleaning of the working face: clean the working face 2 until the hard bottom and level it.

[0115] 2.3. Digging and setting up a sump pit: Dig down a sump pit 9 in the middle of the working face 2. The dimension of the sump pit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com