An extrusion method for in-situ construction of geopolymer

A geopolymer, on-site construction technology, used in roads, road repair, roads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

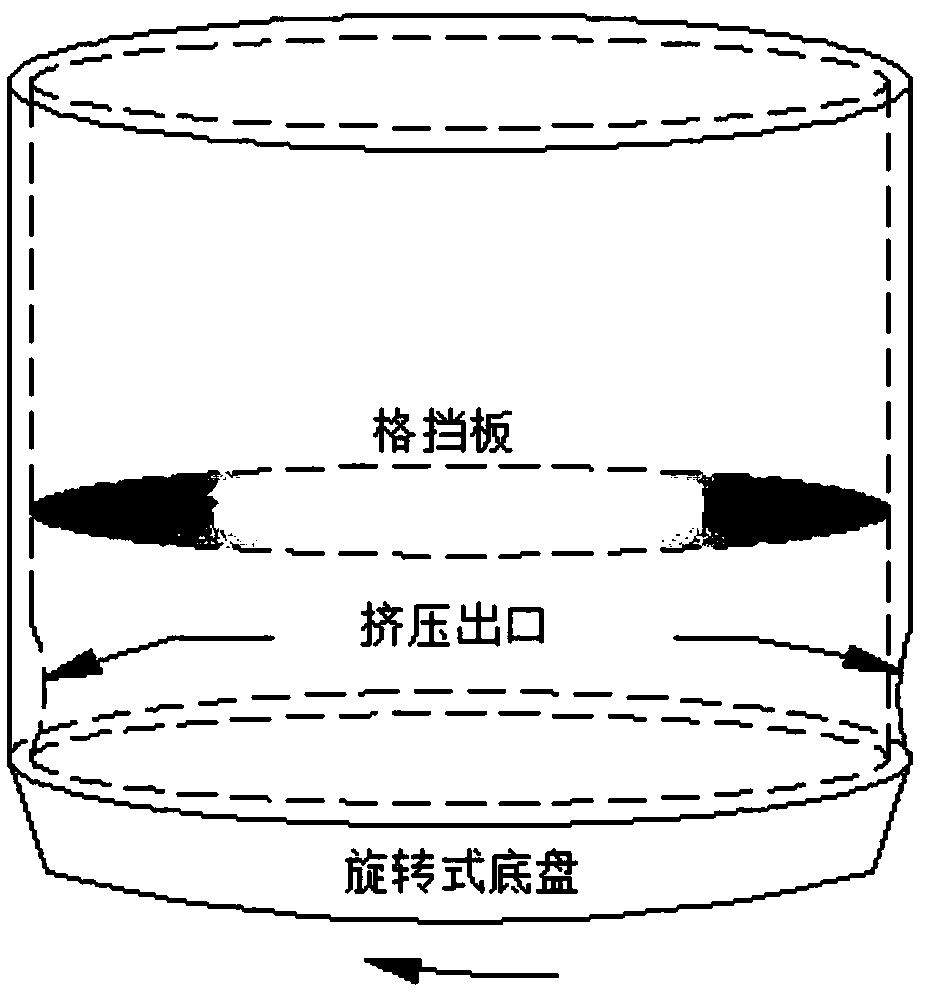

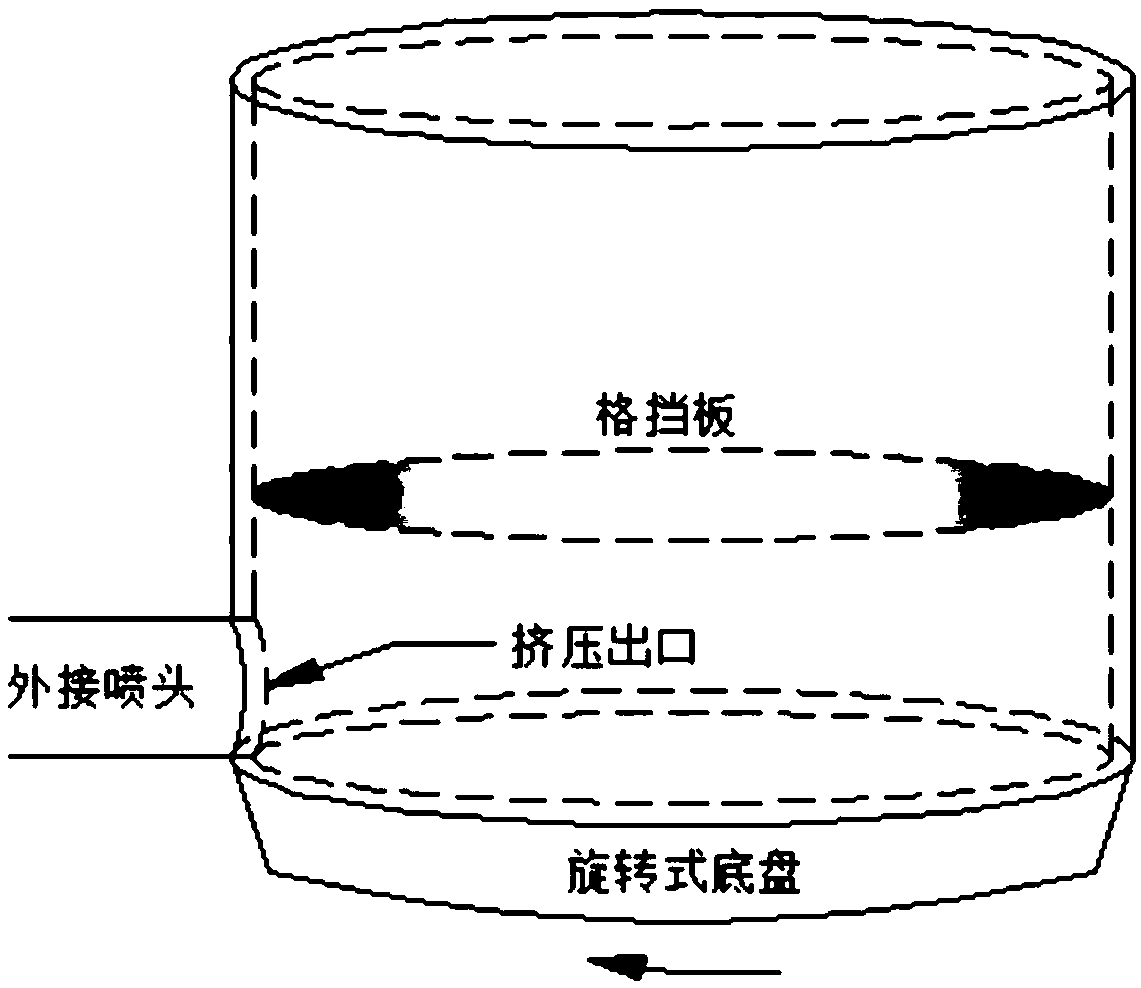

[0014] Such as figure 1 , figure 2 As shown, the grid baffle is connected with the lifting system to provide power for the whole extrusion process. In order to ensure the formation of a closed system between the double-layer stirring pot and the grid baffle, a rubber sleeve is set at the ring of the grid baffle. The double-layer stirring pot is composed of inner and outer layers, which can rotate with each other, and extrusion outlets are respectively set at the bottom. During the stirring process, the inner and outer extrusion outlets are misaligned with each other to ensure the sealing of the mixing pot, and the inner and outer extrusion outlets overlap each other during the extrusion process to realize the smooth extrusion of the geopolymer.

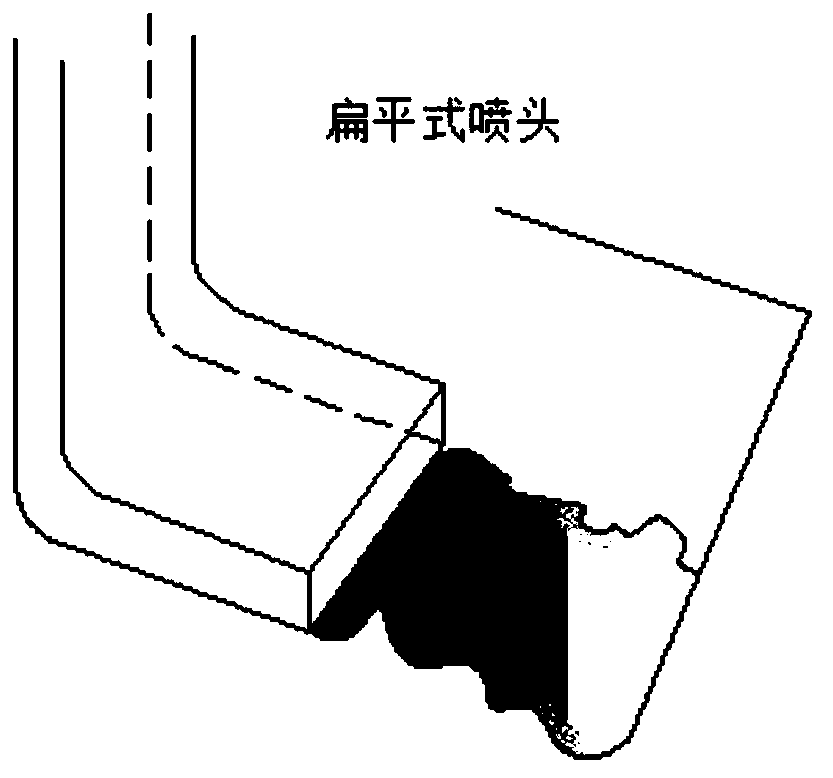

[0015] Such as image 3 As shown, when a large volume of paving is required, the flat nozzle can be used to lay geopolymer materials faster and more smoothly, and it is mostly used for paving roads or runways.

[0016] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com