A mobile bypass cable laying and conveying equipment

A bypass cable, mobile technology, used in overhead line/cable equipment, transportation and packaging, transportation of filamentous materials, etc., can solve problems such as damage to bypass cables, safety accidents, and heavy workloads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

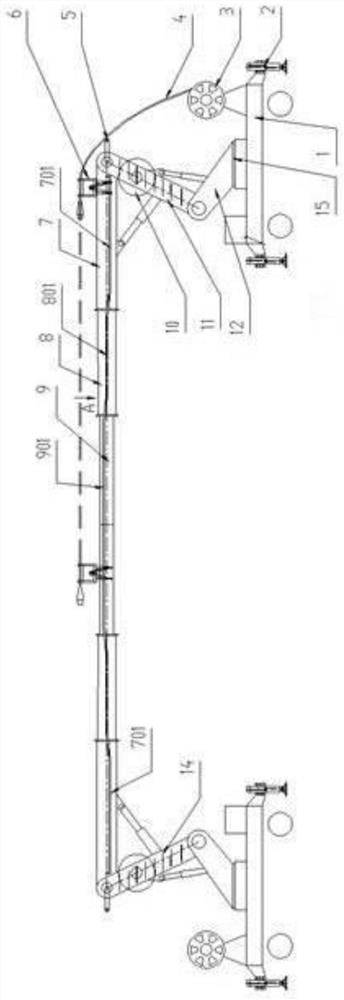

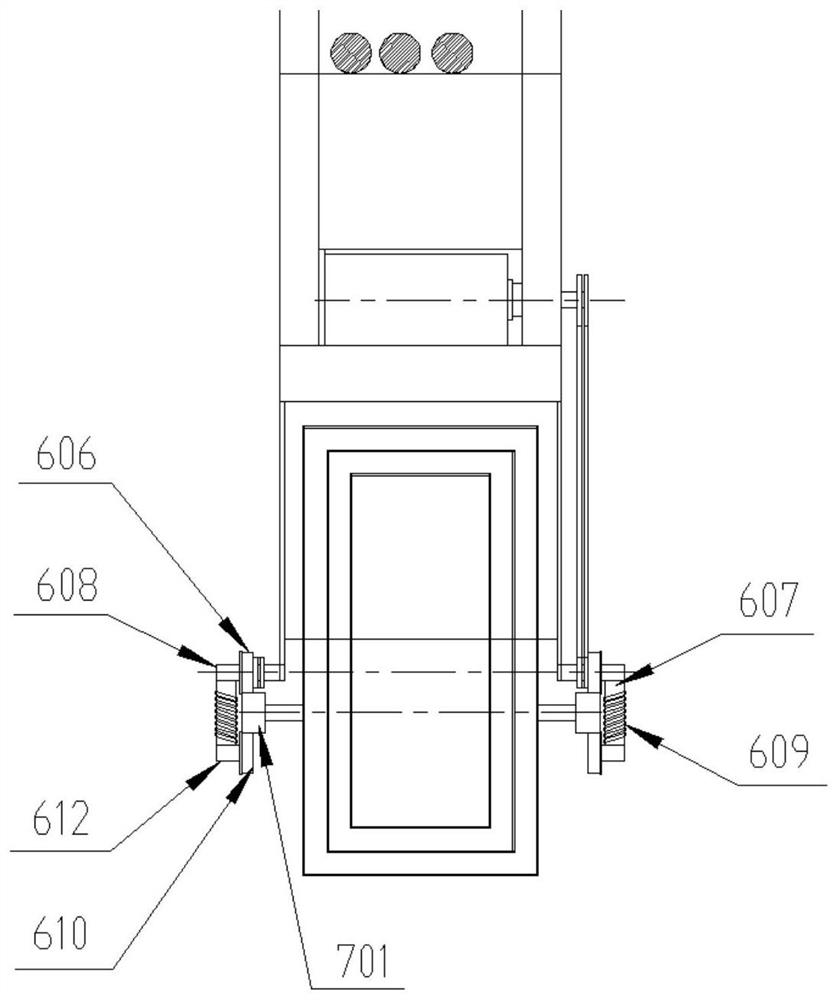

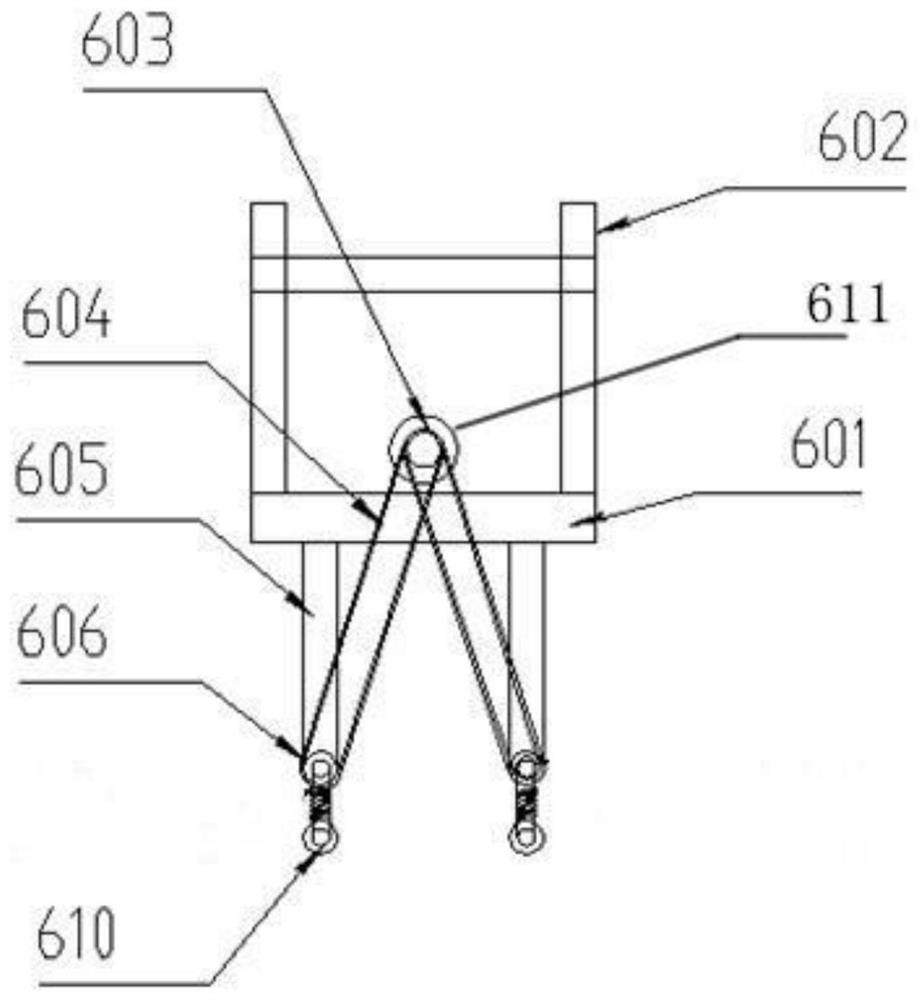

[0027] Embodiment one, as Figure 1 to Figure 5 As shown, a mobile bypass cable laying and conveying equipment includes two car bodies 1 symmetrically arranged on both sides of the road. The luffing mechanism is movably connected with a telescopic arm 7, and the telescopic arm 7 is provided with two telescopic joints, that is, a two-section telescopic joint 8 and a three-section telescopic joint 9, and the two sides of the telescopic arm 7 are fixed with a delivery track 701 by brackets, and two joints The two sides of the expansion joint 8 are fixed with a two-section conveying track 801 through brackets, and the two sides of the three-section expansion joint 9 are fixed with a three-section transmission track 901 through a bracket. Each bracket is fixed at the front end of each expansion joint. The distance between the conveying tracks on both sides of the telescopic joint is the same, and the one-section conveying track 701, the second-section conveying track 801 and the th...

Embodiment 2

[0035] Embodiment two, when the road is narrow, use a car body 1 to be located on the side of the road, all the other are the same as embodiment one, directly make the telescoping arm on the top of the car body 1 cross the road when in use, and put the bypass cable in the air Erection past opposite.

Embodiment 3

[0036] Embodiment 3, in order to facilitate the operation, a power system is separately provided on the car body 1 as required, and the power system provides kinetic energy for the car body 1, the jib luffing mechanism, the telescopic arm 7, the slewing mechanism 15 and the traction structure 6, and others are the same as those in the embodiment One is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com