Preparation method of superhydrophobic cotton and linen textile fabric

A technology for textile fabrics and water cotton is applied in the field of preparation of super-hydrophobic cotton and linen textile fabrics, which can solve the problems of easy water absorption of cotton and linen fabrics, and achieve the effects of increasing microscopic morphology, increasing roughness and improving hydrophobicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

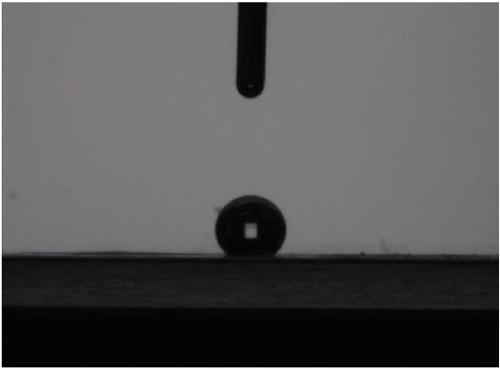

Image

Examples

Embodiment 1

[0024] A kind of preparation method of superhydrophobic cotton linen textile fabric, comprises the following steps:

[0025] 1) Soak the cotton and linen textile fabric in water for 4 hours, take it out and put it in a steam tank for steam treatment for 20 minutes, the steam temperature is 90°C;

[0026] 2) Add 3 g of carboxymethyl chitosan into 100 mL of deionized water, stir to dissolve, then add 0.2 g of sodium periodate, heat up to 50 ° C, and stir for 1 hour to obtain a reaction solution;

[0027] 3) Immerse the cotton and hemp textile fabric in the reaction solution of step 2), then add 0.01mol hydrochloric acid catalyst, heat to 70°C, and react for 3 hours;

[0028] 4) After the reaction in step 3), add 2gSiO 2 Micron particles and 1g ZnO micron particles, where SiO 2 The particle size of the micron particles is 10 μm, and the particle size of the zinc oxide micron particles is 60 μm. Stir ultrasonically for 10 min at 30° C., raise the temperature to 40° C., add 1 g T...

Embodiment 2

[0033] A kind of preparation method of superhydrophobic cotton linen textile fabric, comprises the following steps:

[0034] 1) Soak the cotton and linen textile fabric in water for 5 hours, take it out, put it into a steam tank for steam treatment for 23 minutes, and the steam temperature is 90°C;

[0035] 2) Add 3.5g of carboxymethyl chitosan into 100mL of deionized water, stir to dissolve, then add 0.3g of sodium periodate, heat up to 52°C, stir for 1 hour to obtain a reaction solution;

[0036] 3) Immerse the cotton and hemp textile fabric in the reaction solution of step 2), then add 0.01mol hydrochloric acid catalyst, heat to 75°C, and react for 3.5h;

[0037] 4) After the reaction in step 3), add 2.2gSiO 2 micron particles and 1.5g ZnO micron particles, where SiO 2The particle size of the micron particles is 10 μm, the particle size of the zinc oxide micron particles is 60 μm, ultrasonically stir for 12 min at 32°C, raise the temperature to 45°C, add 1gTi(SO 4 ) 2 a...

Embodiment 3

[0042] A kind of preparation method of superhydrophobic cotton linen textile fabric, comprises the following steps:

[0043] 1) Soak the cotton and linen textile fabric in water for 6 hours, take it out and put it in a steam tank for steam treatment for 25 minutes, the steam temperature is 96°C;

[0044] 2) Add 4g of carboxymethyl chitosan into 120mL of deionized water, stir to dissolve, then add 0.35g of sodium periodate, heat up to 55°C, and stir for 1.5h to obtain a reaction solution;

[0045] 3) Immerse the cotton and hemp textile fabric in the reaction solution of step 2), then add 0.02mol hydrochloric acid catalyst, heat to 76°C, and react for 4 hours;

[0046] 4) After the reaction in step 3), add 2.3gSiO 2 micron particles and 1.6g ZnO micron particles, where SiO 2 The particle size of the micron particles is 15 μm, the particle size of the zinc oxide micron particles is 70 μm, ultrasonically stir for 16 min at 33°C, raise the temperature to 47°C, add 1.5g Ti(SO 4 )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com