A kind of high toughness wear-resisting composite coating and the method for depositing it on the hot working convex mold

A technology of composite coating and composite layer, which is applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of matching and not reaching the production efficiency of the die, so as to improve the service life and eliminate fatigue failure , enhance the effect of wear resistance and thermal fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

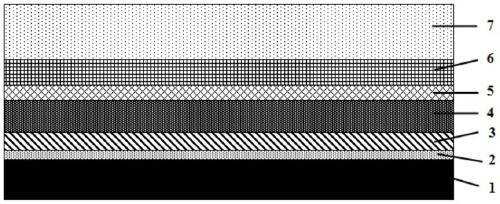

[0053] Such as figure 2 As shown, the present invention provides a high-toughness wear-resistant composite coating, including a Cr bonding layer 2, a CrN transition layer 3, a CrAlN gradient support layer 4, a Cr metal layer 5, a CrAlN / AlCrN composite layer 6 and CrAlVN / CrAlSiN functional layer 7 .

[0054] The specific functions and related characteristics of each layer are as follows:

[0055] Cr binding layer 2: the thickness is 80-160nm, which is used to improve the bonding force between the composite coating and the mold matrix;

[0056] CrN transition layer 3: the thickness is 150-300nm, and the Al atomic percentage is 10-35 at.% (atom percentage content), which is used to improve the bonding strength between the bonding layer and the supporting layer;

[0057] CrAlN gradient support layer 4: the thickness is 450-900nm, which is used to improve the structural hardness and reduce the internal stress caused by the lattice mismatch between the composite coating and the b...

Embodiment 2

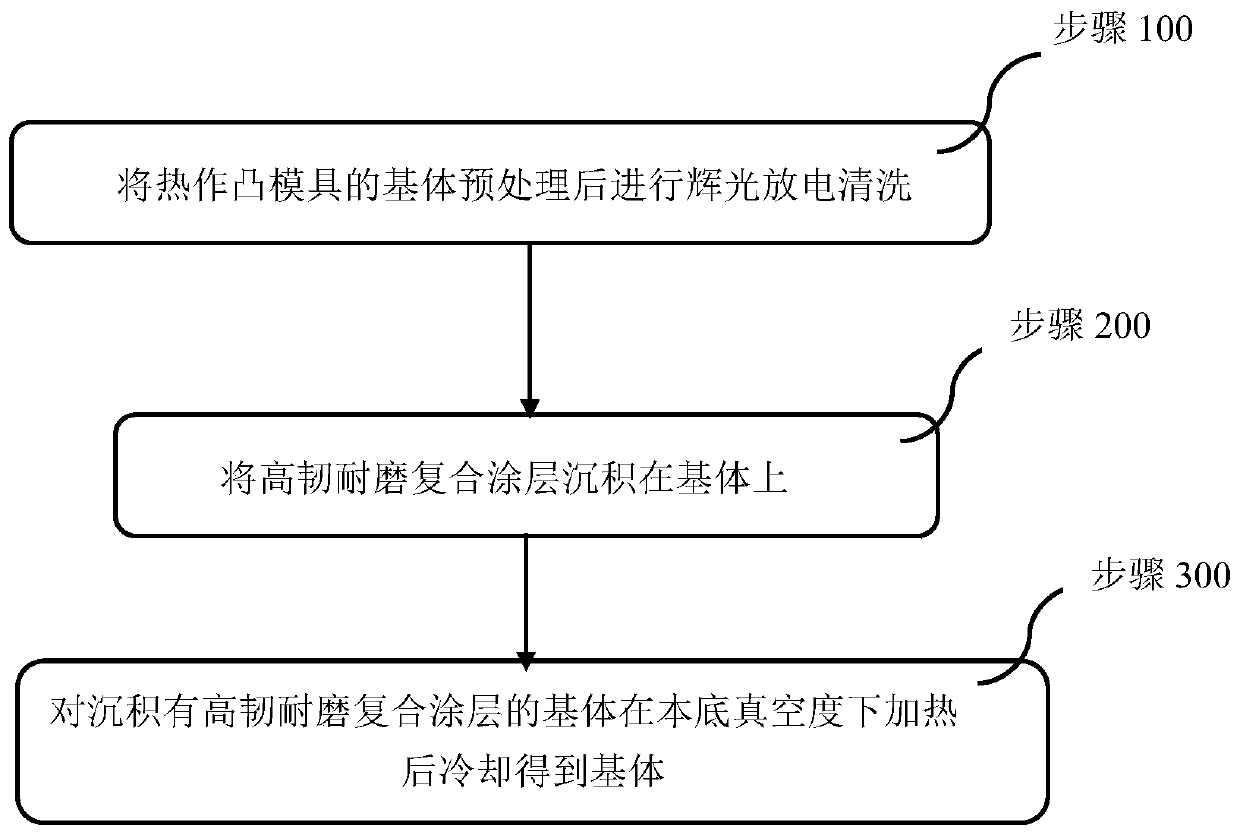

[0067] Such as Figure 1 to Figure 3 As shown, the present invention also provides a method for depositing a high-toughness wear-resistant composite coating on a hot work punch, including the following three steps:

[0068] Step 100, performing glow discharge cleaning after pretreating the substrate of the hot working convex mold;

[0069] Step 200, depositing a high-toughness wear-resistant composite coating on the substrate;

[0070] Step 300, heating the substrate deposited with the high-toughness wear-resistant composite coating under the background vacuum degree, and then cooling to obtain the substrate.

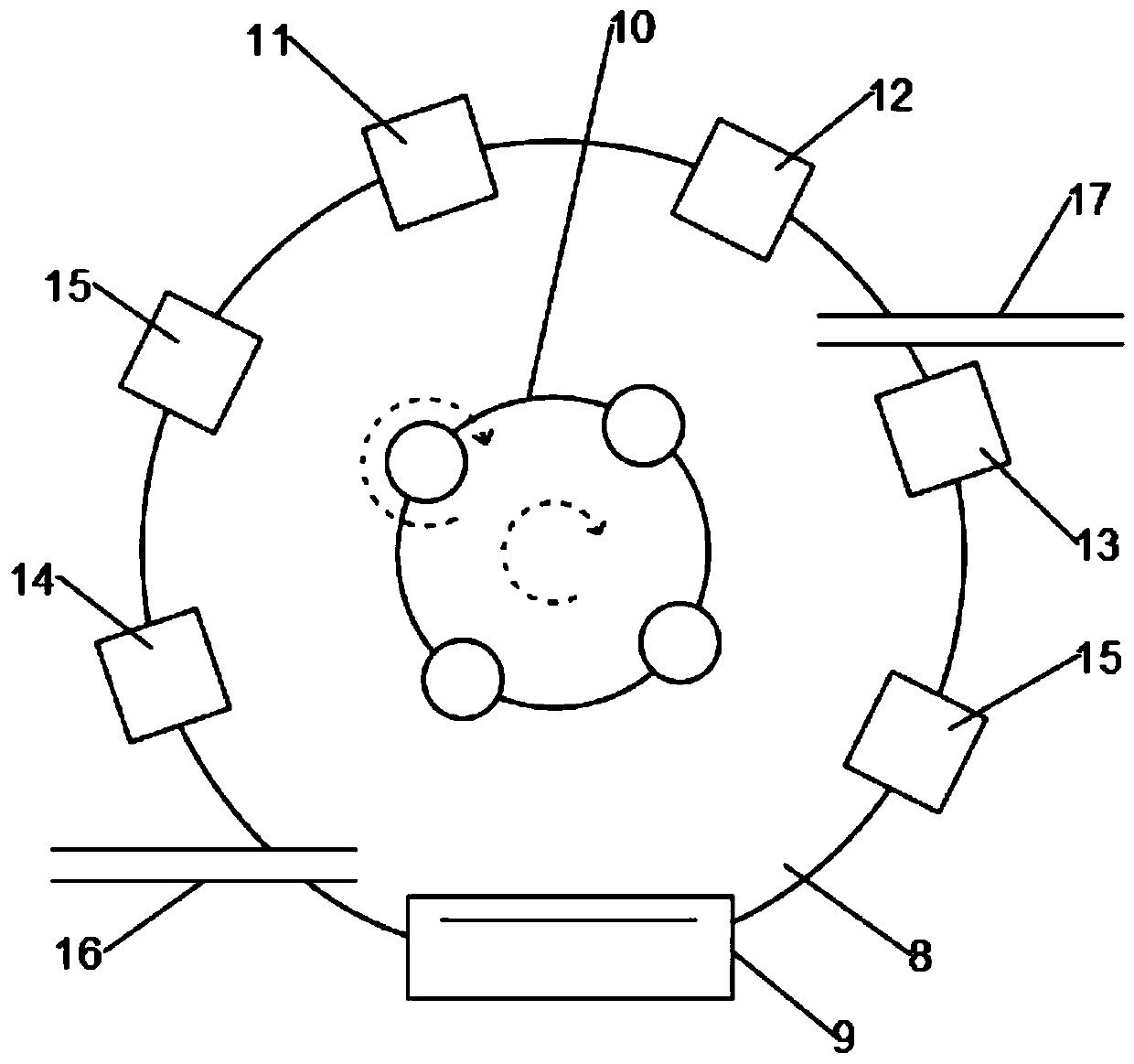

[0071] Such as figure 2 As shown, it is a schematic diagram of the target distribution of the existing vacuum cathode arc ion plating equipment for depositing the composite coating of the present invention, including a rotatable base 10, an ion source 9 and a vacuum chamber 8 installed on the base 10, Cr alloy Target 11; CrAl alloy target 12; AlCr alloy target 13; C...

Embodiment 3

[0096] The difference from Example 2 is:

[0097] The present invention also provides a method for depositing a high-toughness and wear-resistant composite coating on other materials' hot-working convex molds. The substrate of the hot-working convex molds is made of 4Cr5MoSiV1 material, including the following three steps:

[0098] Step 100, performing glow discharge cleaning after pretreating the substrate of the hot working convex mold;

[0099] Step 200, depositing a high-toughness wear-resistant composite coating on the substrate;

[0100] Step 300, heating the substrate deposited with the high-toughness wear-resistant composite coating under the background vacuum degree, and then cooling to obtain the substrate.

[0101] In the present embodiment, one of the accurate parameters is selected as an example for illustration, which does not affect the essence of the realization result of the present embodiment. The deposition method of the composite coating on the hot work pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com