Colloidal polymer, preparation method thereof and polymer weak gel drilling fluid

A polymer and gel-forming technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of weak gel system losing plugging and leaking channels and adjusting rheology, strict on-site construction requirements, aluminum cross-linking To solve the problems of precipitation and precipitation of the agent, it can achieve the effect of good filtrate reduction performance, good viscosity improvement effect and high viscosity retention rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

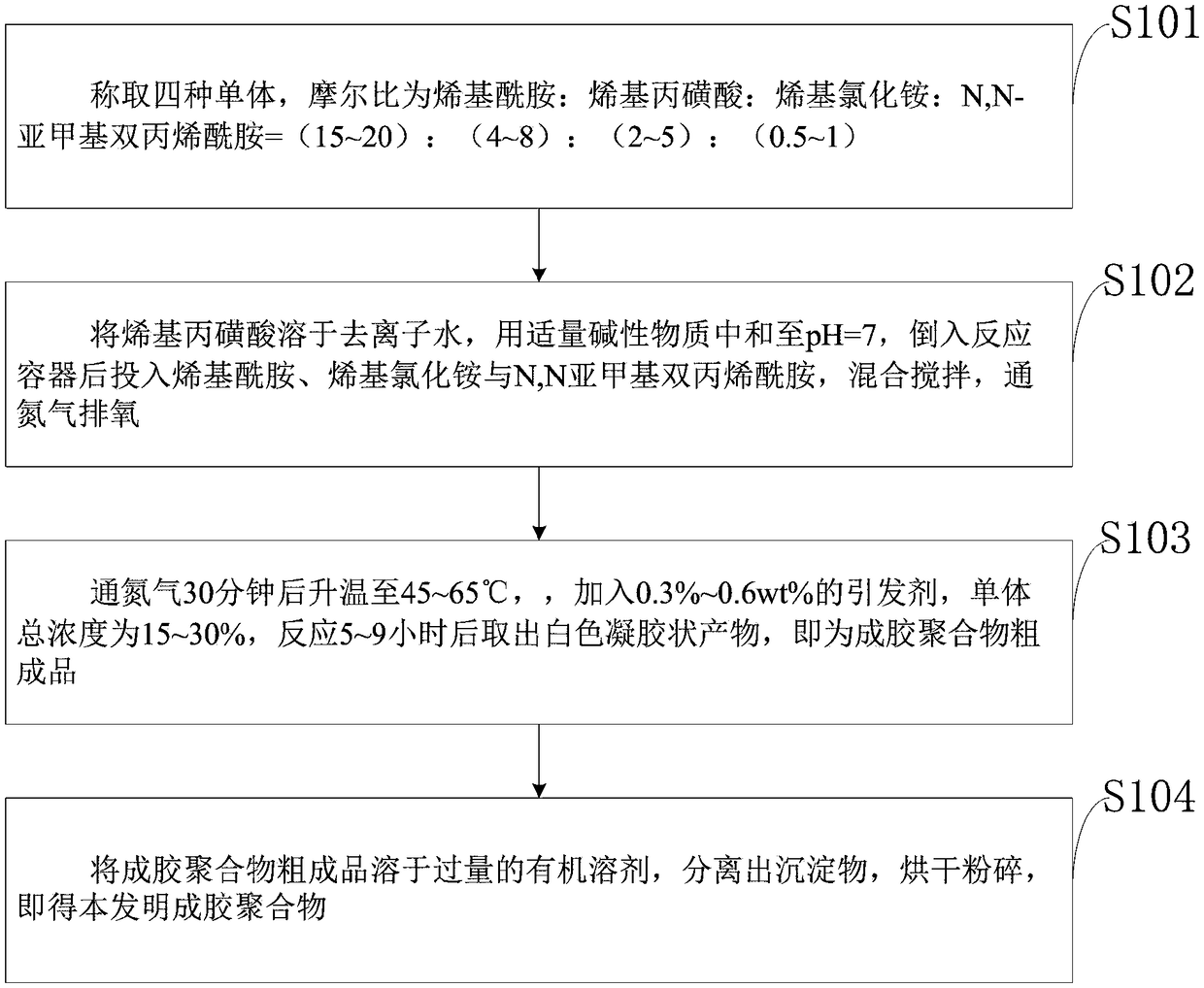

[0041] Such as figure 1 As shown, the gel-forming polymer and preparation method thereof provided by the embodiments of the present invention comprise the following steps:

[0042] S101: Weigh four monomers, the molar ratio is alkenyl amide: alkenyl propanesulfonic acid: alkenyl ammonium chloride: N,N-methylenebisacrylamide = (15~20): (4~8) :(2~5):(0.5~1);

[0043] S102: Dissolve alkenylpropanesulfonic acid in deionized water, neutralize it with an appropriate amount of alkaline substance to pH = 7, pour it into a reaction vessel, and put alkenyl amide, alkenyl ammonium chloride and N,N-methylenebis Acrylamide, mixed and stirred, nitrogen exhausted;

[0044] S103: After passing nitrogen for 30 minutes, heat up to 45-65°C, add 0.3%-0.6wt% initiator, the total monomer concentration is 15-30%, and take out the white gel-like product after reacting for 5-9 hours, that is It is a crude product of gel-forming polymer;

[0045] S104: dissolving the crude product of the gel-formi...

Embodiment 1

[0052] Preparation of gel-forming polymer PTTS-1

[0053] Dissolve 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in deionized water, neutralize the solution to pH=7~8 with NaOH, and add acrylamide (AM), trihydroxyethyl allyl Ammonium chloride (TAAC) and N,N-methylene bisacrylamide (MBA) are mixed with the neutralized solution, and then added to a three-necked flask with a thermometer and a reflux device, stirred, nitrogen and oxygen exhausted. Gradually raise the temperature to 50°C, add 0.3% initiator ammonium persulfate-sodium bisulfite after passing nitrogen for 30 minutes, and the total monomer concentration is 20%, after reacting for 7 hours, wash the white gel-like product with absolute ethanol Fully wash, separate the precipitate, dry and pulverize at high temperature to obtain the gel-forming polymer PTTS-1, and obtain the target product with a yield of 91.5%. The reaction formula is as follows:

[0054]

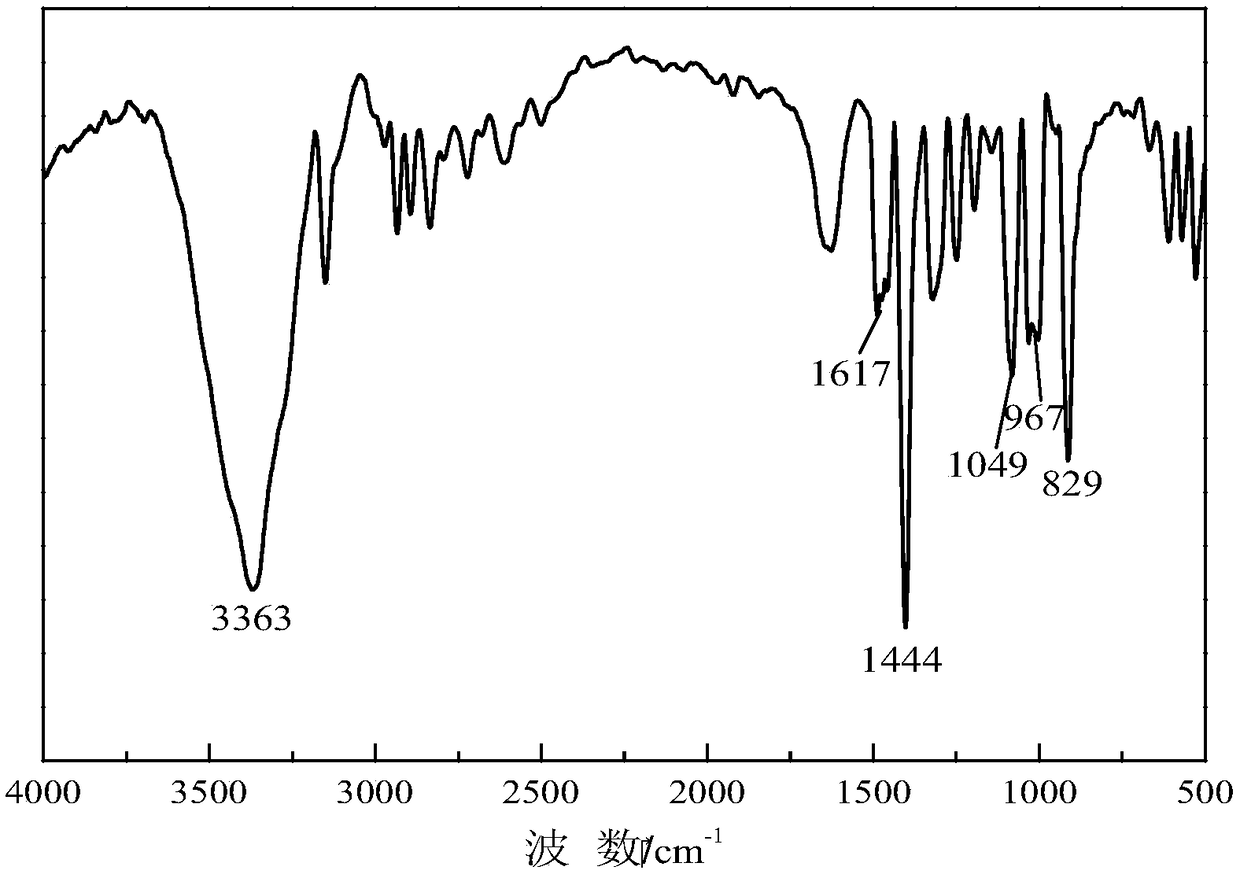

[0055] Structural characterization of gel-forming polyme...

Embodiment 2

[0060] Preparation of gel-forming polymer PTTS-2

[0061] Dissolve 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in deionized water, neutralize the solution to pH=7~8 with NaOH, and N,N-dimethylacrylamide (DMAA), Trihydroxyethyl allyl ammonium chloride (TAAC) and N, N-methylenebisacrylamide (MBA) are mixed with the neutralized solution, and then added to a three-necked flask with a thermometer and a reflux device, stirred, and passed Nitrogen exhaust. Gradually raise the temperature to 50°C, add 0.3% initiator ammonium persulfate-sodium bisulfite after passing nitrogen for 30 minutes, and the total monomer concentration is 20%, after reacting for 7 hours, wash the white gel-like product with absolute ethanol Fully wash, separate the precipitate, dry and pulverize at high temperature to obtain the gel-forming polymer PTTS-2, and obtain the target product with a yield of 91.2%. The reaction formula is as follows:

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com