High solid content and economical tannic acid resistant two-component white environment-friendly waterborne primer

A water-based primer, economical technology, applied in primers, coatings, polyurea/polyurethane coatings, etc., can solve the problems of high VOC content, poor sealing, white primer precipitation, etc., and achieve anti-tannin Improve acid performance, improve construction convenience, and paint film performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

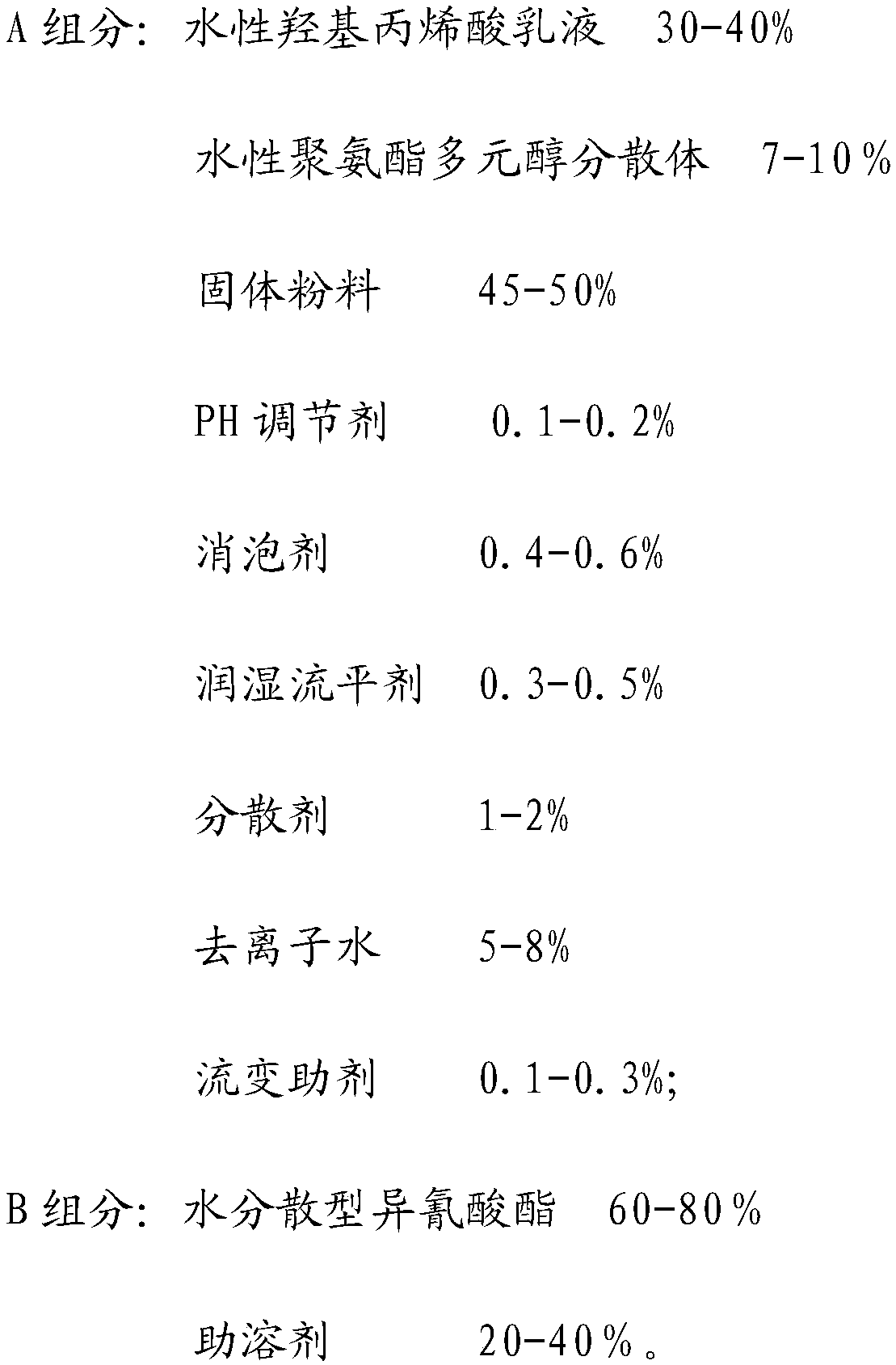

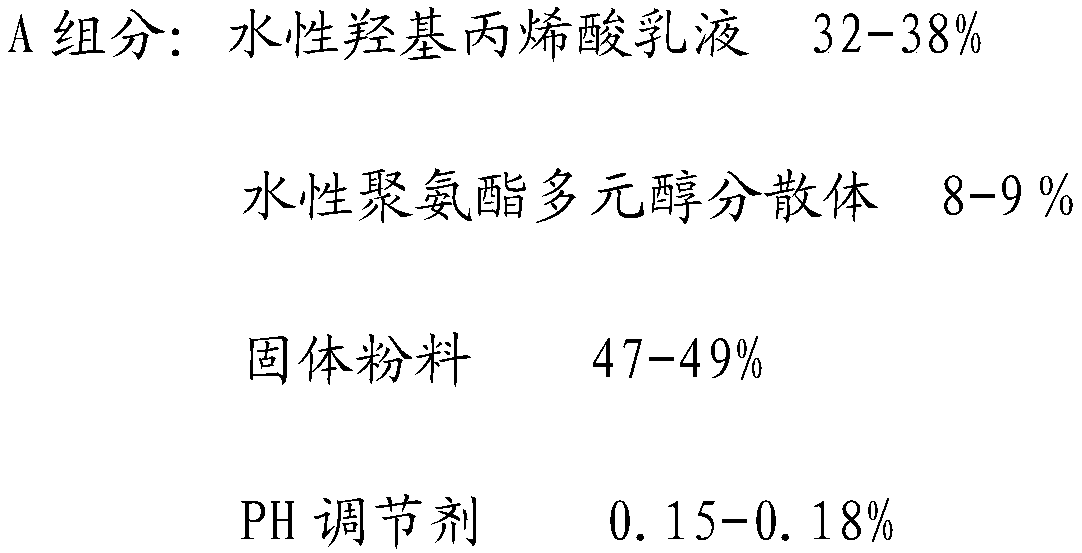

Method used

Image

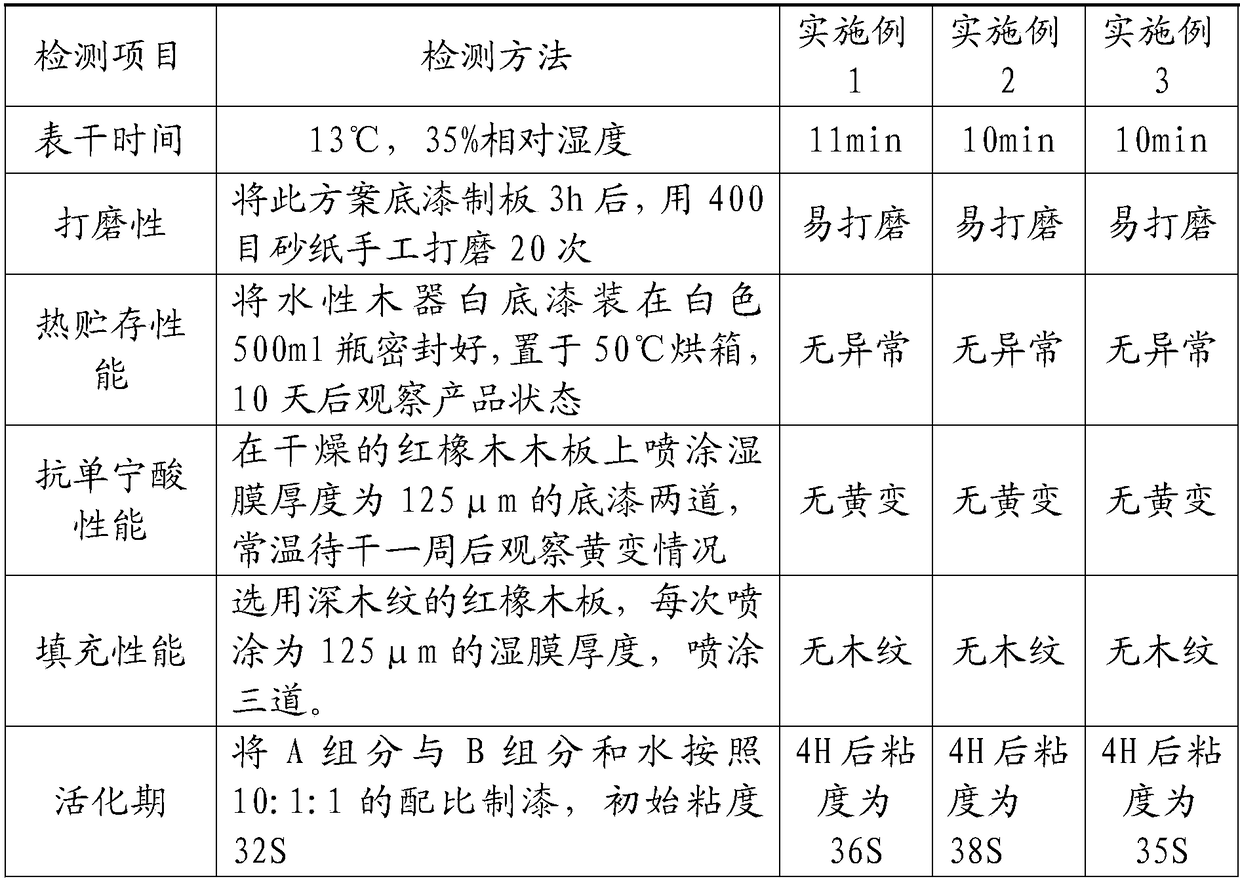

Examples

Embodiment 1

[0074] Preparation of component A: Step a: Preparation of white pulp: add 1% quick and easy to 5% deionized water for medium-speed dispersion for 10 minutes, then add 0.1% dimethylethanolamine and continue to disperse for 5 minutes, then add 0.4% BYK-024 Disperse at high speed for 10 minutes, then add 45% domestic rutile titanium dioxide and disperse at high speed for 15 minutes, and finally put the mixture into a grinder to grind until the fineness is ≤20 μm, and set aside;

[0075] Step b: Add 30% Opeldi AC31 and 7% Covestro A2601 into another new stock pot, add a mixture of 0.2% dimethylethanolamine and 0.2% deionized water at a medium speed, and disperse at a medium speed for 5 Minutes to make emulsion;

[0076] Step c: Add 0.4% BKY-024 and 0.3% BKY-346 to the emulsion prepared in step b and disperse at high speed for 10 minutes to prepare mixed solution c for later use;

[0077] Step d: Add the white slurry prepared in step a to the mixed solution c and disperse at a med...

Embodiment 2

[0081] Preparation of component A: Step a: Preparation of white pulp: add 2% Tego755W to 8% deionized water for medium speed dispersion for 15 minutes, then add 0.2% AWP-95 and continue dispersion for 10 minutes, then add 0.6% TEG0902W at high speed Disperse for 15 minutes, then add 50% 1250 mesh talc powder and disperse at high speed for 20 minutes, and finally put the mixture into a grinder to grind until the fineness is ≤20 μm, and set aside;

[0082] Step b: Add 40% AC2598 and 10% XP2755 of Oubaodi to another new stock pot, add a mixture of 0.3% AWP-95 and 0.3% deionized water at a medium speed, and disperse at a medium speed for 5 minutes to obtain Lotion;

[0083] Step c: Add 0.6% TEG0810 and 0.5% TEG0270 to the emulsion prepared in step b and disperse at high speed for 15 minutes to prepare mixed solution c for later use;

[0084] Step d: Add the white slurry prepared in step a to the mixed solution c and disperse at a medium speed for 20 minutes; then add 3% deionized...

Embodiment 3

[0088] Preparation of component A: Step a: Preparation of white pulp: add 1.5% quick and easy to 6.5% deionized water for medium speed dispersion for 10 minutes, then add 0.15% dimethylethanolamine and continue to disperse for 10 minutes, then add 0.5% TEG0810 for high speed dispersion After 10 minutes, add 47% 1250 mesh talc powder to disperse at high speed for 20 minutes, and finally put the mixture into a grinder to grind to a fineness of ≤20 μm, and set aside;

[0089] Step b: Add 35% DSM XK103 and 8.5% Covestro A2601 into another new stock pot, add the mixture of 0.2% AMP-95 and 0.2% deionized water at medium speed, and disperse at medium speed for 5 minutes , to prepare the emulsion;

[0090] Step c: Add 0.5% TEG0810 and 0.4% TEG0270 to the emulsion prepared in step b and disperse at high speed for 10 minutes to prepare mixed solution c for later use;

[0091] Step d: Add the white slurry prepared in step a to the mixed solution c and disperse at a medium speed for 20 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com