Carbon nanotube/fiber concrete for 3D printing and preparation method thereof

A fiber reinforced concrete and carbon nanotube technology, which is applied in the field of building materials, can solve the problems of limited structural type, increased steel skeleton, insufficient toughness, etc., and achieves the effect of convenient material selection, satisfying applicability, and improving bending toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In parts by weight, weigh 8.1 parts of 42.5 sulfoaluminate cement, 6.5 parts of mineral powder, 1.6 parts of silica fume, 4.9 parts of quartz sand, 2.6 parts of water, 0.34 parts of polycarboxylate superplasticizer, and 0.0081 parts of tartaric acid retarder part, 0.16 part of polyvinyl alcohol fiber, 0.0008 part of carbon nanotube, and 0.0032 part of PVP dispersant.

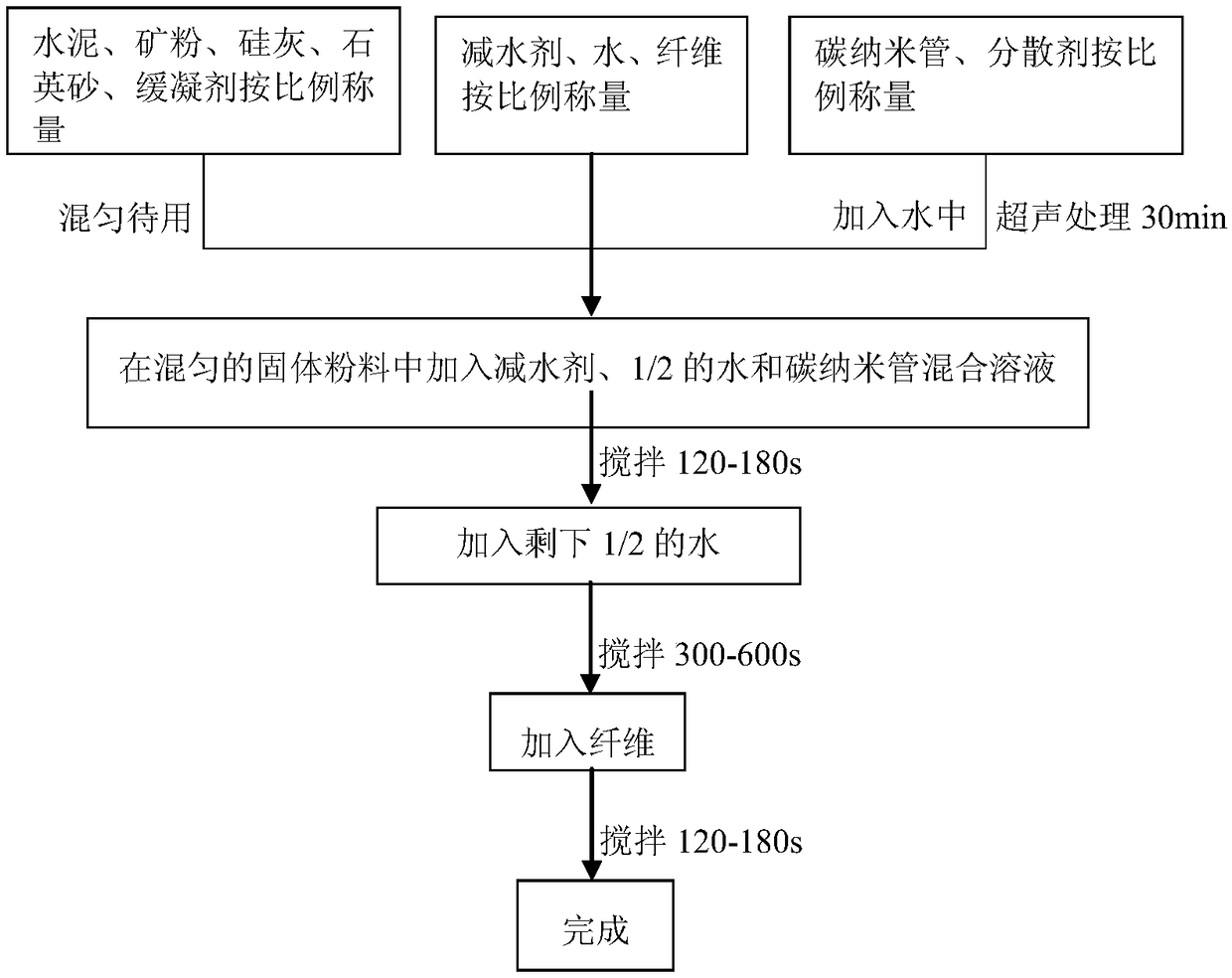

[0083] The specific construction method is to weigh cement, mineral powder, silica fume, quartz sand, and retarder in proportion and then mix them to obtain solid powder for use; weigh water reducing agent, water, and fiber in proportion for use; Carbon nanotubes and dispersant were weighed in proportion and added to water, and ultrasonically treated for 30 minutes to obtain a carbon nanotube mixed solution; water reducer and 1 / 2 of water were added to the mixed solid powder (the amount of water used here After subtracting the amount of water in the mixed solution) and the carbon nanotube mixed solution, ...

Embodiment 2

[0087] In parts by weight, weigh 8.1 parts of 52.5 sulfoaluminate cement, 6.5 parts of mineral powder, 1.6 parts of silica fume, 4.9 parts of quartz sand, 2.6 parts of water, 0.45 parts of polycarboxylate superplasticizer, sodium gluconate retarding 0.016 part of agent, 0.1 part of polyvinyl alcohol fiber, 0.0016 part of carbon nanotube, 0.0065 part of PVP dispersant.

[0088] Concrete construction method is with embodiment 1.

[0089] The performance test results of the prepared carbon nanotube / fiber concrete material are: the fluidity is 163mm; the initial setting time is 80min, the final setting time is 160min; the 1d compressive strength is 17.63MPa, the 3d compressive strength is 46.61MPa, and the 7d compressive strength is 82.71MPa , 28d compressive strength 101.35MPa; 1d flexural strength 7.84MPa, 3d flexural strength 11.55MPa, 7d flexural strength 15.85MPa, 28d flexural strength 17.65MPa.

Embodiment 3

[0091] In parts by weight, weigh 8.4 parts of 42.5 sulfoaluminate cement, 6.7 parts of mineral powder, 1.7 parts of silica fume, 5.0 parts of quartz sand, 2.35 parts of water, 0.39 parts of polycarboxylate superplasticizer, 0.001 part of starch ether, 0.016 part of tartaric acid retarder, 0.1 part of polyvinyl alcohol fiber, 0.004 part of carbon nanotube, 0.016 part of PVP dispersant.

[0092] Refer to Example 1 for the specific construction method.

[0093] The performance test results of the prepared carbon nanotube / fiber concrete material are: fluidity is 159mm; initial setting time is 54min, final setting time is 79min; 1d compressive strength is 47.68MPa, 3d compressive strength is 69.35MPa, and 7d compressive strength is 77.58MPa , 28d compressive strength 89.26MPa; 1d flexural strength 9.75MPa, 3d flexural strength 11.54MPa, 7d flexural strength 13.88MPa, 28d flexural strength 14.59MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

| Initial setting time | aaaaa | aaaaa |

| Final setting time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com