Thermal insulation and degradable ceramic lunch box and preparation method

A lunch box and ceramic technology, which is applied in the field of thermal insulation and degradable ceramic lunch boxes and its preparation, can solve the problems of restricting the development of the fast food industry, the fast food box cannot be heated, and the human body is damaged, and achieves light weight, is not easy to break, and reduces pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

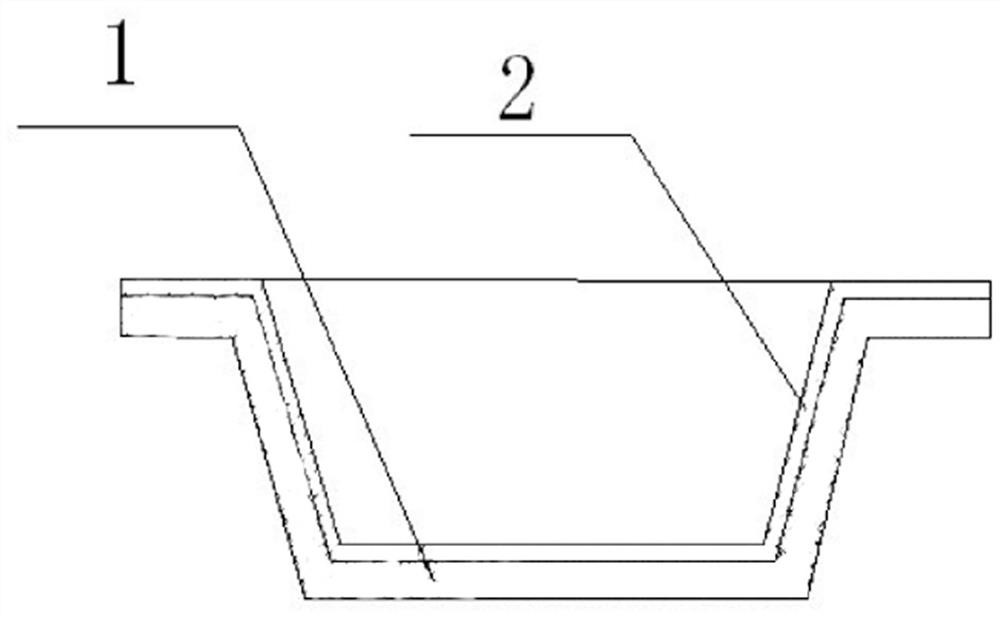

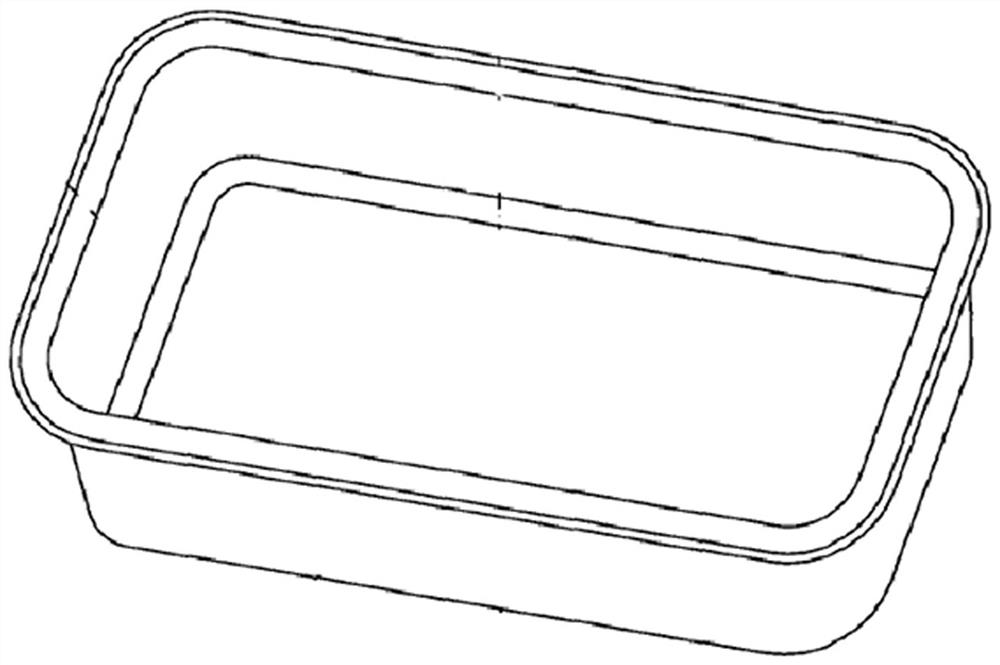

[0052] The thermal insulation and degradable ceramic lunch box is divided into two layers, the inner layer 2 is a ceramic layer, and the outer layer 1 is a degradable fiber layer.

[0053]The inner layer 2 includes the following raw materials in parts by weight: 30 parts of pottery clay, 10 parts of chitosan, 5 parts of epoxy resin, 3 parts of adhesive, 3 parts of oil repellent, cationic paper fluorocarbon oil repellent according to Guangxi University The product prepared in the example of the patent applied for (cationic paper fluorocarbon oil repellent and its preparation method, application number: 200710024326.8).

[0054] The outer layer 1 includes the following raw materials in parts by weight: 40 parts of bamboo fiber, 10 parts of chitosan, 3 parts of sodium alginate, 2 parts of adhesive, 1 part of oil repellent, cationic paper fluorocarbon oil repellent according to Guangxi University The product prepared in the example of the patent applied for (cationic paper fluoroc...

Embodiment 2

[0062] The thermal insulation and degradable ceramic lunch box is divided into two layers, the inner layer 2 is a ceramic layer, and the outer layer 1 is a degradable fiber layer.

[0063] The inner layer 2 includes the following raw materials in parts by weight: 35 parts of pottery clay, 12 parts of chitosan, 6 parts of epoxy resin, 4 parts of adhesive, 4 parts of oil repellent, cationic paper fluorocarbon oil repellent according to Guangxi University The product prepared in the example of the patent applied for (cationic paper fluorocarbon oil repellent and its preparation method, application number: 200710024326.8).

[0064] The outer layer 1 includes the following raw materials in parts by weight: 45 parts of bamboo fiber, 12 parts of chitosan, 4 parts of sodium alginate, 3 parts of adhesive, 2 parts of oil repellent, cationic paper fluorocarbon oil repellent according to Guangxi University Applied patent (cationic paper fluorocarbon oil repellent and its preparation metho...

Embodiment 3

[0072] The thermal insulation and degradable ceramic lunch box is divided into two layers, the inner layer 2 is a ceramic layer, and the outer layer 1 is a degradable fiber layer.

[0073] The inner layer 2 includes the following raw materials in parts by weight: 40 parts of pottery clay, 11 parts of chitosan, 7 parts of epoxy resin, 3 parts of adhesive, 4 parts of oil repellent, cationic paper fluorocarbon oil repellent according to Guangxi University The product prepared in the example of the patent applied for (cationic paper fluorocarbon oil repellent and its preparation method, application number: 200710024326.8).

[0074] The outer layer 1 comprises the following raw materials in parts by weight: 60 parts of bamboo fiber, 15 parts of chitosan, 4 parts of sodium alginate, 4 parts of adhesive, 2 parts of oil repellent, cationic paper fluorocarbon oil repellent according to Guangxi University The product prepared in the example of the patent applied for (cationic paper fluo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com