A method for preparing saponite crystals under hydrothermal conditions

A saponite and crystal technology, which is applied in the field of preparing saponite crystals under hydrothermal conditions, can solve the problems of saponite artificial synthesis, poor safety and operability, high impurity content of layered clay catalysts, and limited application and development. Achieve the effects of easy control of experimental conditions, better application performance, and convenient raw material acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

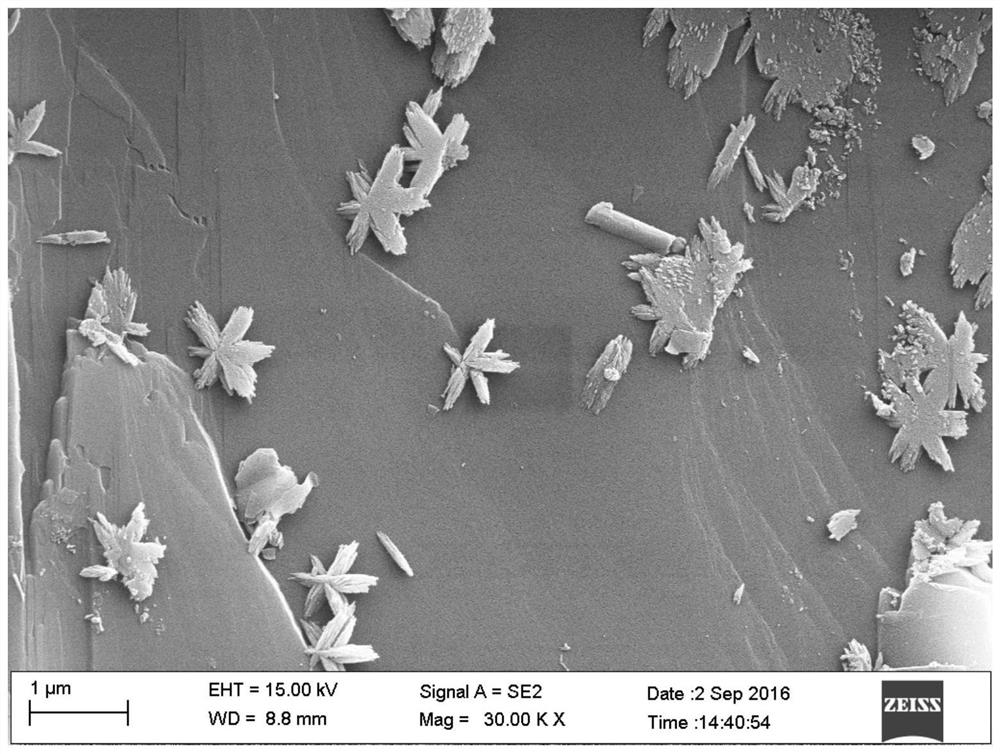

Embodiment 1

[0027] Prepare an acid solution with a pH of 5.5-6.5 at room temperature for later use; put the acid solution and the amphibole particles after removal of impurities into a high-temperature airtight container at the same time, and let it stand for 10 minutes at room temperature to ensure that the amphibole in different experimental groups The time for initial acidification was the same. Heat the airtight container containing the pretreated sample to 150°C for 5 to 10 days, so that the ions in the hornblende are fully dissolved and separated, and then precipitate on the surface of the hornblende to obtain saponite crystal nuclei; close after the holding time Heating system, let the airtight container cool down to 100°C, place it in a well-ventilated place and let it stand for 2 to 3 hours, let it cool down to room temperature naturally, this process can make the saponite crystal fully grow and exist stably. The precipitate was fully washed with deionized water and then dried at...

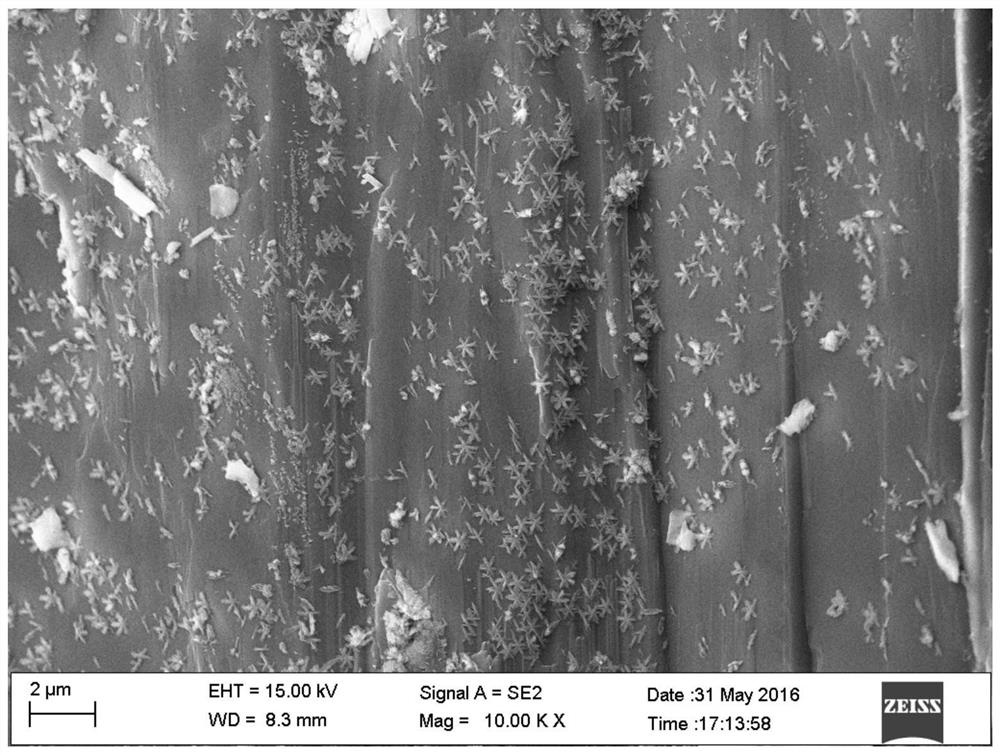

Embodiment 2

[0029] Prepare an acid solution with a pH of 5.5-6.5 at room temperature for later use; put the acid solution and the amphibole particles after removal of impurities into a high-temperature airtight container at the same time, and let it stand for 10 minutes at room temperature to ensure that the amphibole in different experimental groups The time for initial acidification was the same. Heat the airtight container containing the pretreated sample to 210°C for 5 to 10 days, so that the ions in the hornblende are fully dissolved and precipitated on the surface of the hornblende to obtain saponite crystal nuclei; close after the holding time Heating system, let the airtight container cool down to 100°C, place it in a well-ventilated place and let it stand for 2 to 3 hours, let it cool down to room temperature naturally, this process can make the saponite crystal fully grow and exist stably. The precipitate was fully washed with deionized water and then dried at 50°C for about 30 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com