Hub unit and assembling installation method thereof

A wheel hub unit and wheel hub technology, which is applied in the field of auto parts, can solve the problems of bearing chamber wear, reduce bearing service life, and high assembly cost, and achieve the effect of reducing manufacturing precision, saving time and cost, and simplifying assembly workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

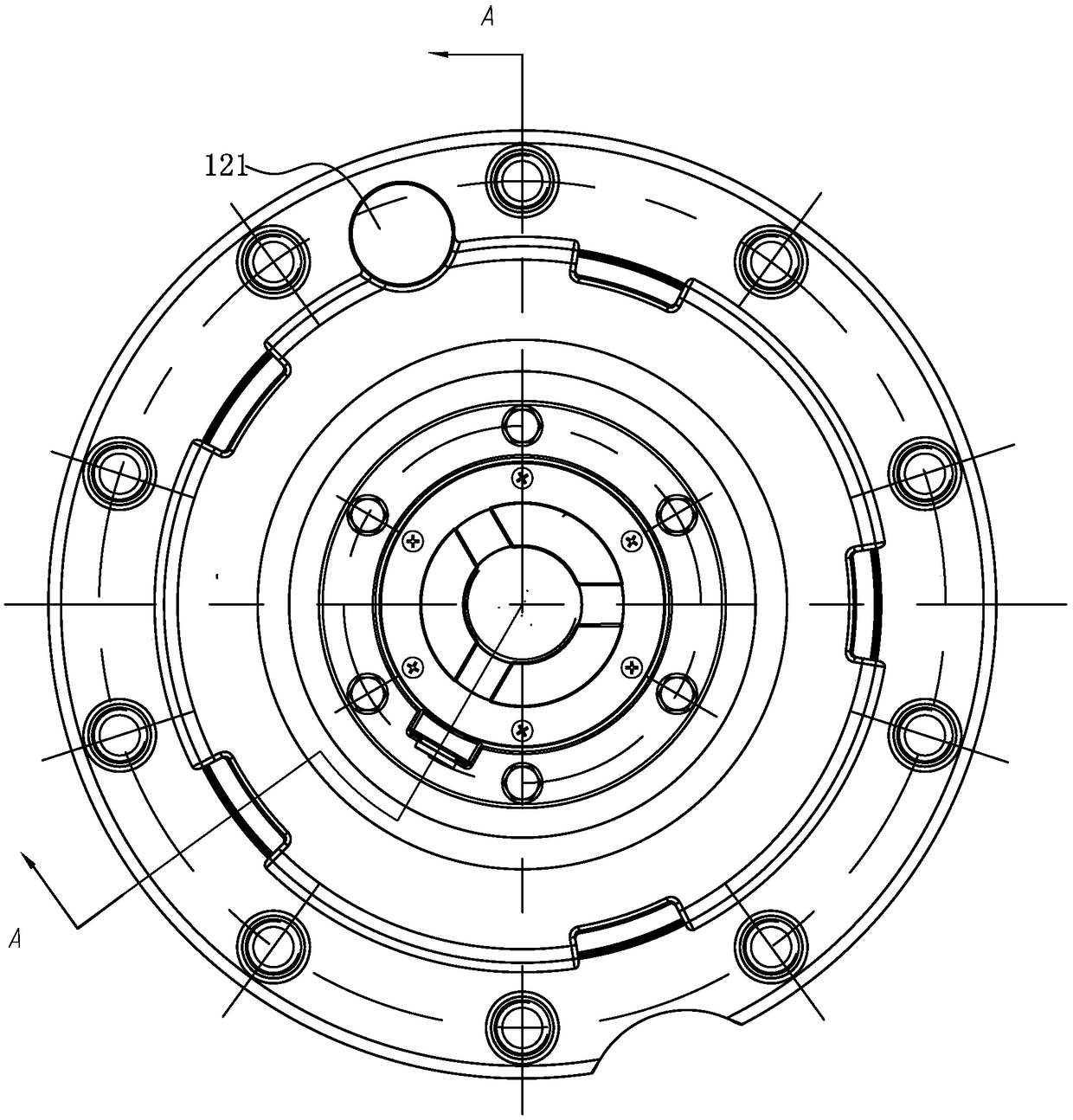

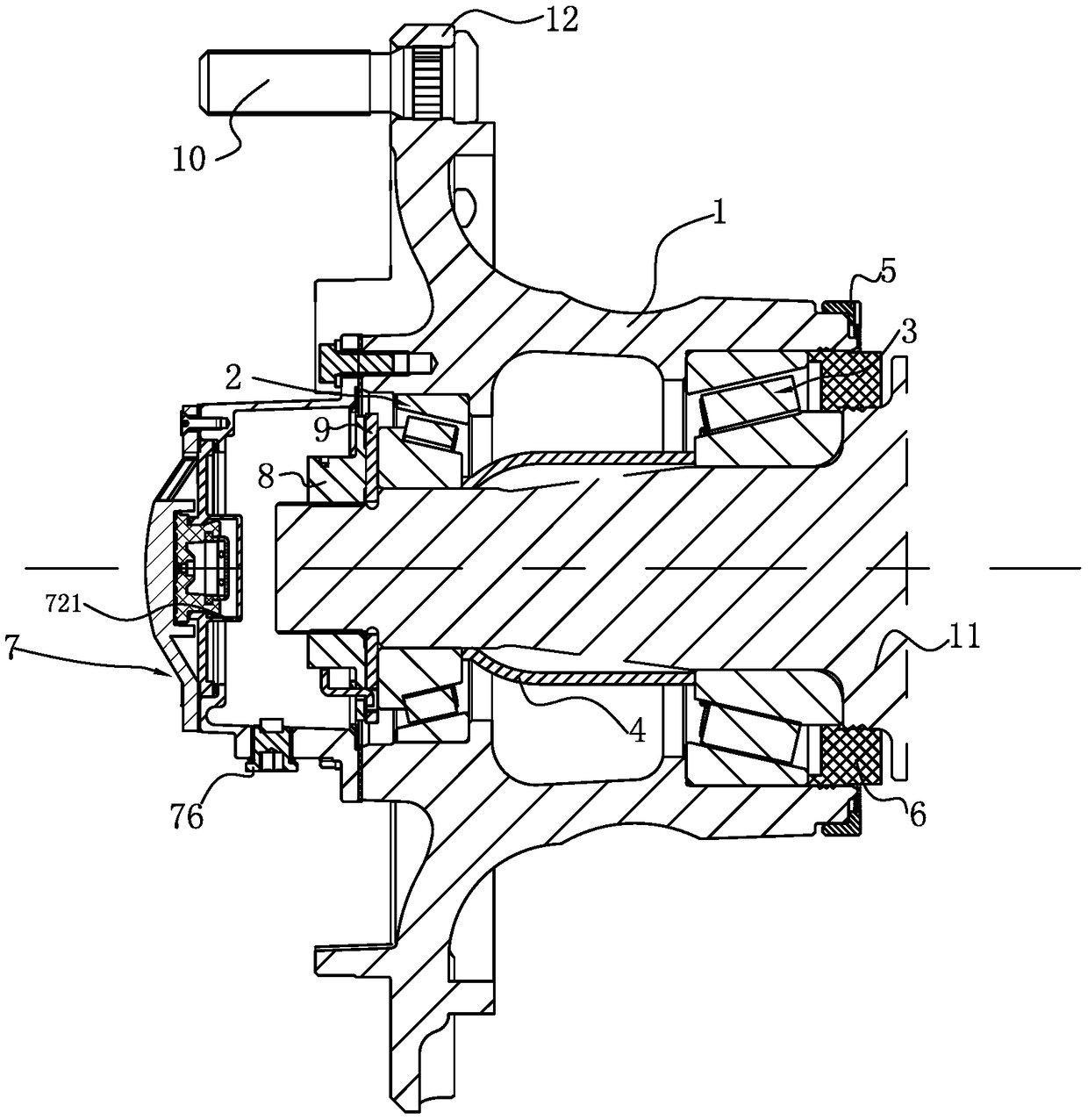

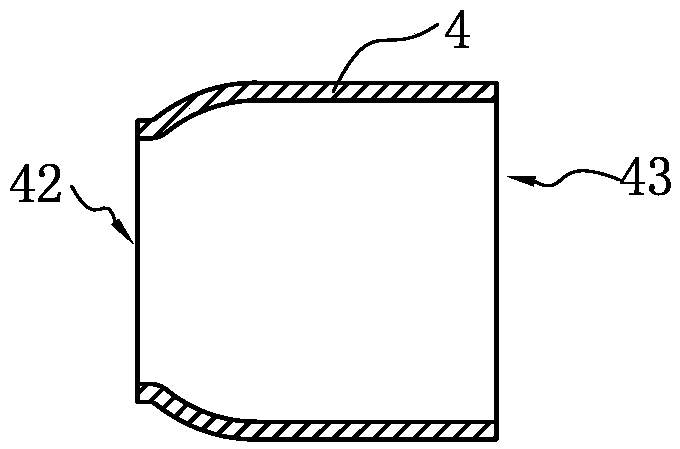

[0038] Such as figure 1 and figure 2 As shown in the hub unit, the hub unit is rotatably mounted on the steering knuckle 11, the hub body 1 has a first end and a second end, the first end is provided with a first bearing chamber, and the end surface of the first end is fixed The exhaust end cover 7 is provided, the second end is provided with a second bearing chamber, the first bearing chamber is provided with a first bearing 2, the second bearing chamber is provided with a second bearing 3, and the outer peripheral surface of the second end is fixed There is an ABS ring gear 5, and an oil seal 6 is fixed on the inner peripheral surface of the second end.

[0039] The outer peripheral surface of the steering knuckle 11 is in clearance fit with the inner rings of the first bearing 2 and the second bearing 3 respectively, and the outer rings of the first bearing 2 and the second bearing 3 are respectively in interference fit with the hub body 1; the hub body 1 is provided with...

Embodiment 2

[0058] Such as Figure 7 Shown is a schematic diagram of the structure of the hub unit installed on the vehicle axle tube in Embodiment 2 of the present invention. The differences between Embodiment 2 and Embodiment 1 are:

[0059] The hub unit of this embodiment is installed on the drive axle, the hub unit is rotatably installed on the vehicle axle tube 14, and the end surface of the first end portion is not provided with the exhaust end cover 7 .

[0060] The oil injection hole is provided on the peripheral wall of the inner cavity of the hub between the first bearing chamber and the second bearing chamber, and the oil injection hole is threadedly connected with a magnetic screw plug 76 .

[0061] In the assembling steps of the hub unit, the supporting member in step D is equivalent to the oil seal seat 13, and its function is to axially limit the inner ring of the second bearing 3.

[0062] The above-mentioned hub unit is installed on the vehicle axle tube 14, including th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com