Metal lattice plate and manufacturing method thereof

A technology of metal lattice and lattice, applied in the direction of metal layered products, chemical instruments and methods, lamination devices, etc., can solve the problems of overall performance degradation, achieve the goals of improving stability, avoiding weld seams, and improving mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

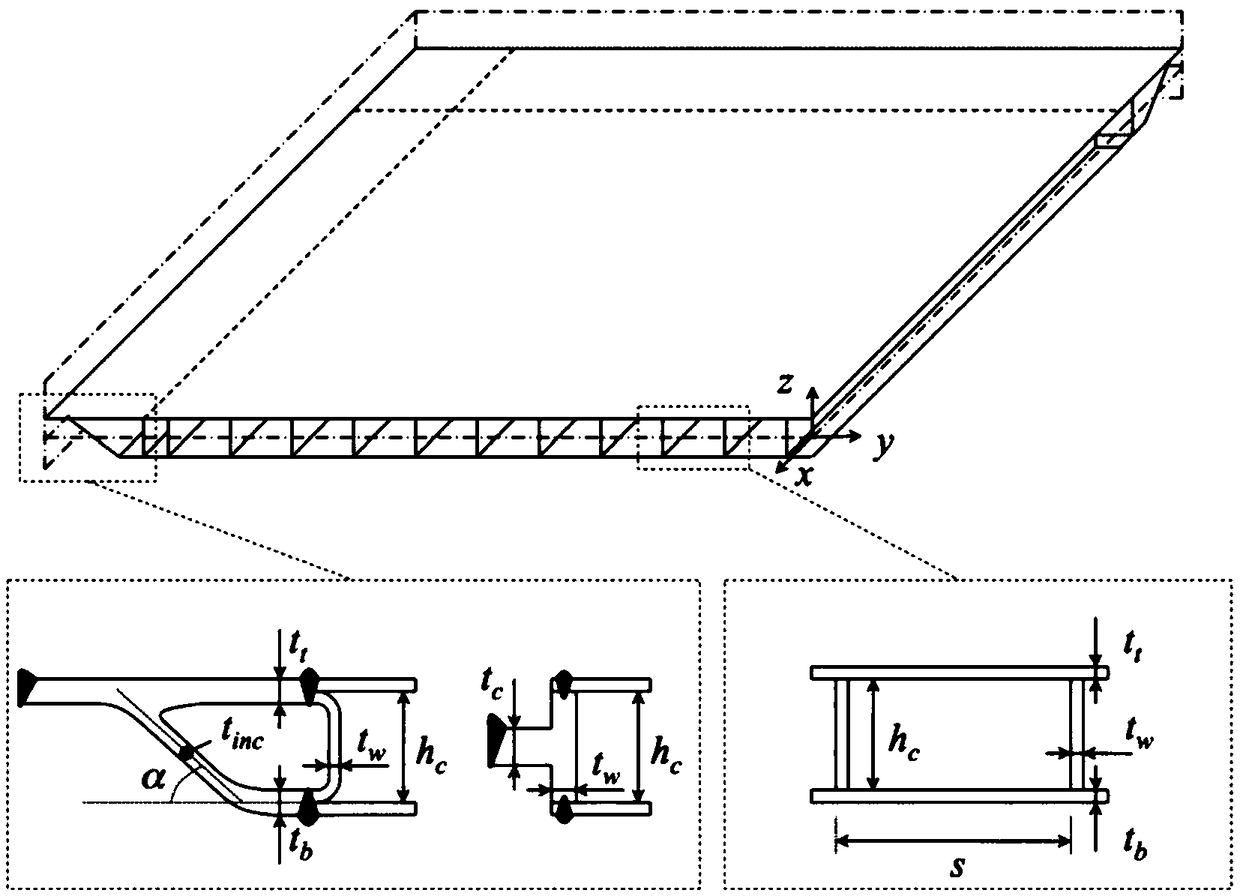

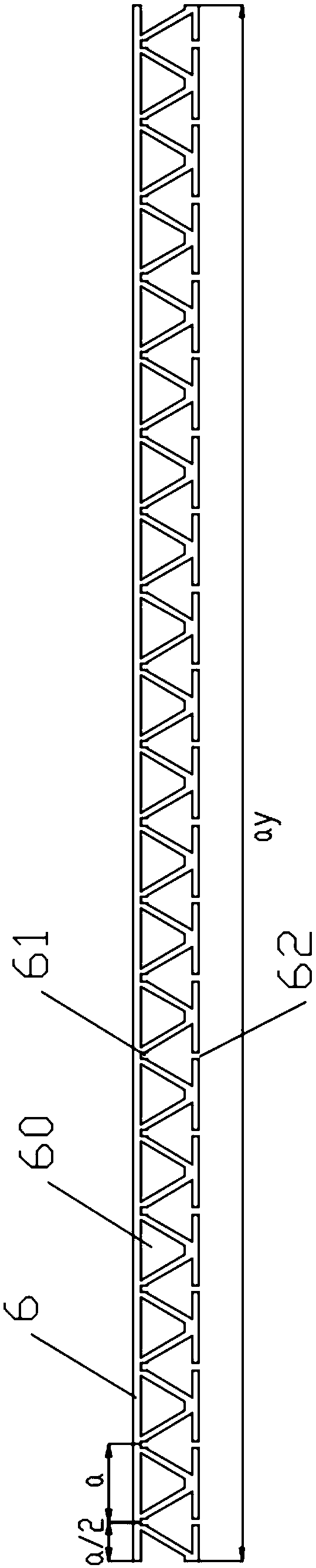

[0041]A metal dot matrix board is characterized in that it comprises a dot matrix board (1), and the dot matrix board (1) includes an upper panel (2) and a lower panel (3) connected as one by a dot matrix core (4), so The lattice core (4) comprises a plurality of longitudinally arranged warp stringers (6) and a plurality of transversely arranged latitudinal stringers (5), and the warp direction stringers (6) and the weft direction stringers (5) Snap connection between each other.

[0042] The latitudinal stringer (5) is in the shape of a strip as a whole, which includes a plurality of continuous latitudinal isosceles triangle units (50), and the upper side of the latitudinal stringer (5) is provided with a plurality of openings upward The outer tenon groove (51) of the latitudinal stringer, the outer tenon groove (51) of the latitudinal stringer is arranged at the triangular apex position of the isosceles triangular unit (50) in the latitudinal direction, and the lower side of...

Embodiment 2

[0048] A novel method for manufacturing a metal dot matrix board connection, characterized in that it comprises the following steps:

[0049] 1) Prepare the upper panel (2) and the lower panel (3) according to the size of the lattice plate. For the lattice plate whose size is n*n (n is an integer multiple of a), the length of the weft stringers (5) is ax, the overhang length of the upper panel square mortise (20) is a / 2, the width is a, the groove depth of the tenon groove is a / 2, and the width is a, and the overhang length of the upper panel semi-square mortise (21) is a / 2, the width is a / 2, the mortise and mortise structures are arranged alternately along the entire joint direction, the mortise and tenon structures of the upper and lower panels of the same dot matrix board are interlaced, and the mortise and tenon structures of the dot matrix board connected to it should be Corresponding to it; its dimensions and structural schematic diagrams are shown in accompanying drawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com