Robot rapid tool changing self-adaptive force control tail end executing device design

A technology of end effector and adaptive controller, which is applied in the direction of automatic grinding control devices, manipulators, grinding machine tools, etc., to achieve the effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

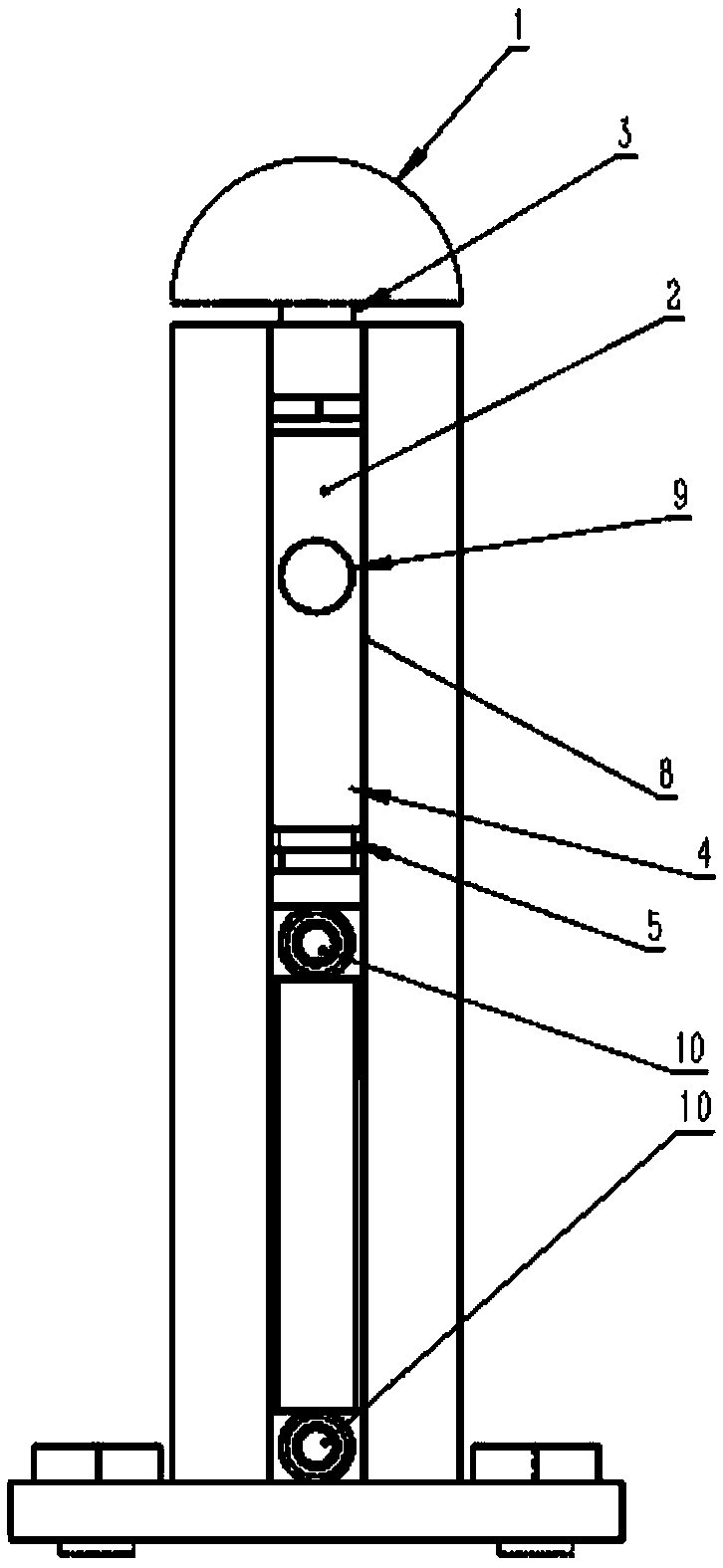

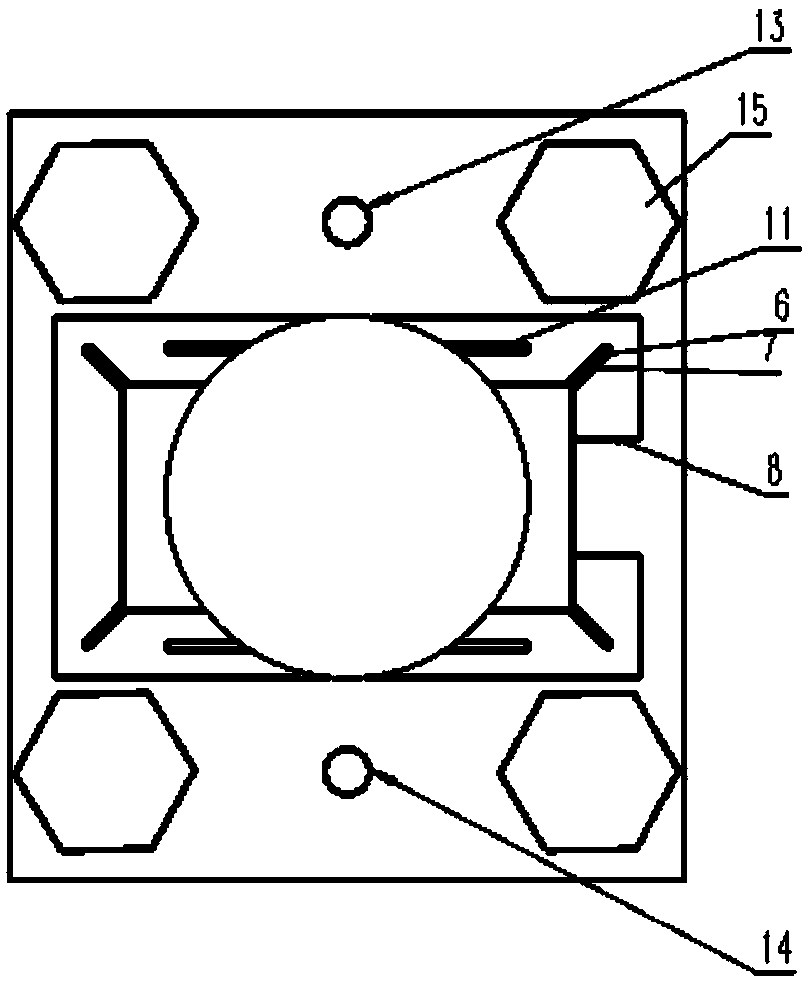

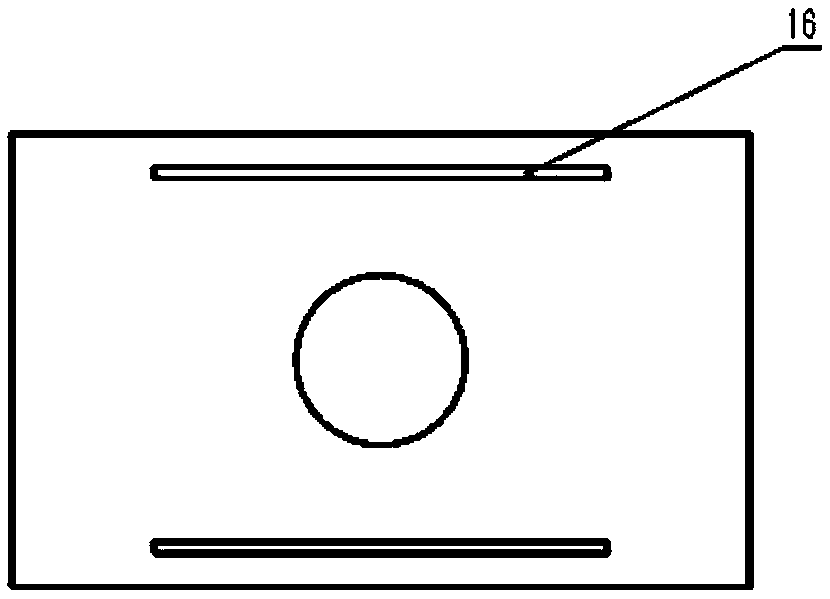

Method used

Image

Examples

Embodiment Construction

[0044] The working principle of the present invention is as follows:

[0045] Before grinding, the standby end effector and the standby tool are placed at the coordinate positions set in advance in the mechanical arm grinding numerical control system. Start the mechanical arm, and the mechanical arm automatically moves to the first docking point, and the end effector is realized through the process of infrared recognition (32), mechanical claw (34) clamping and bolt fastening, and pipe docking point (17) docking. capture. After capturing the end effector, the robotic arm automatically moves to the next docking site to capture the grinding tool. When the tool handle triggers the infrared sensing device, it indicates that the tool has reached the clamping position. At this time, the three pressure adaptive controllers (36) tighten the tool through the action of the pressure control cylinder. After capturing the end effector and the corresponding machining tool, the robotic arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com