Waste textile crushing collection device

A waste textile and collection device technology, applied in the direction of grain processing, etc., can solve the problems that affect cloth processing, consume a lot of manpower and material resources, and textiles are difficult to collect, so as to achieve the effect of improving efficiency and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

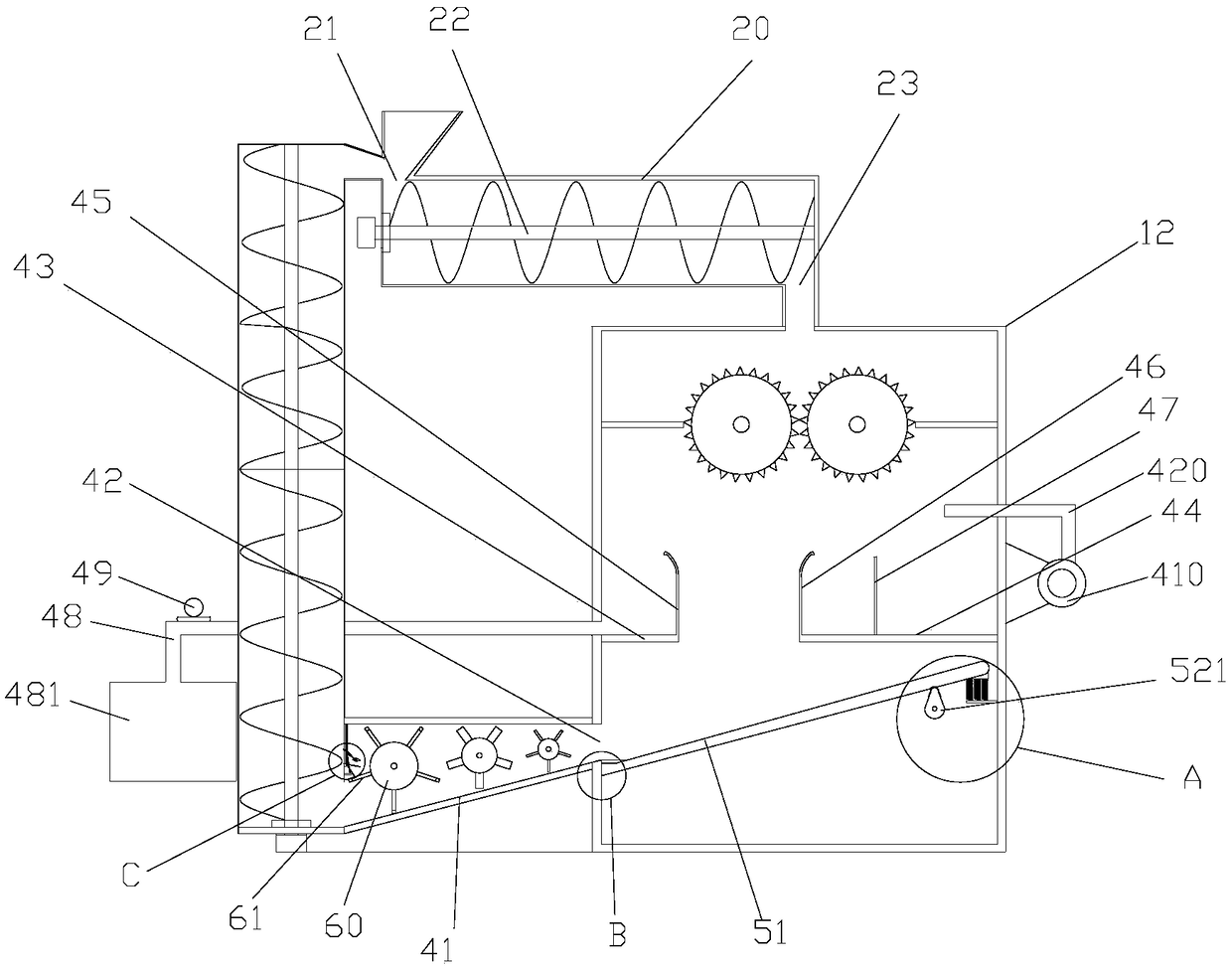

[0031] Such as Figure 8-9 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment discloses a collection assembly for collecting the treated cloth, specifically: the collection assembly includes a collection pipe 48, a Roots blower 49 and a collection box 481, The collection pipe 48 is a metal pipe, one end of the collection pipe 48 communicates with the crushing box, and the other end communicates with the collection box 48, the collection box 48 is a metal box, and the collection box 48 is provided with The material outlet 480 for the material to go out, and the bottom plate of the collection box 48 can move up and down, and the up and down movement is to form an inclined slope, so that the material slides out along the slope.

[0032] Further, the bottom of the bottom plate 491 is provided with a driving component for driving the bottom plate to move up and down, and the driving component includes a first cylinder 482, a first push rod 483...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com