A kind of epoxy-based macroporous/mesoporous polymer material and preparation method thereof

A polymer material, epoxy-based technology, applied in the direction of alkali metal oxides/hydroxides, alkali metal compounds, chemical instruments and methods, etc., to achieve the effects of extreme volatility, good mechanical strength, and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

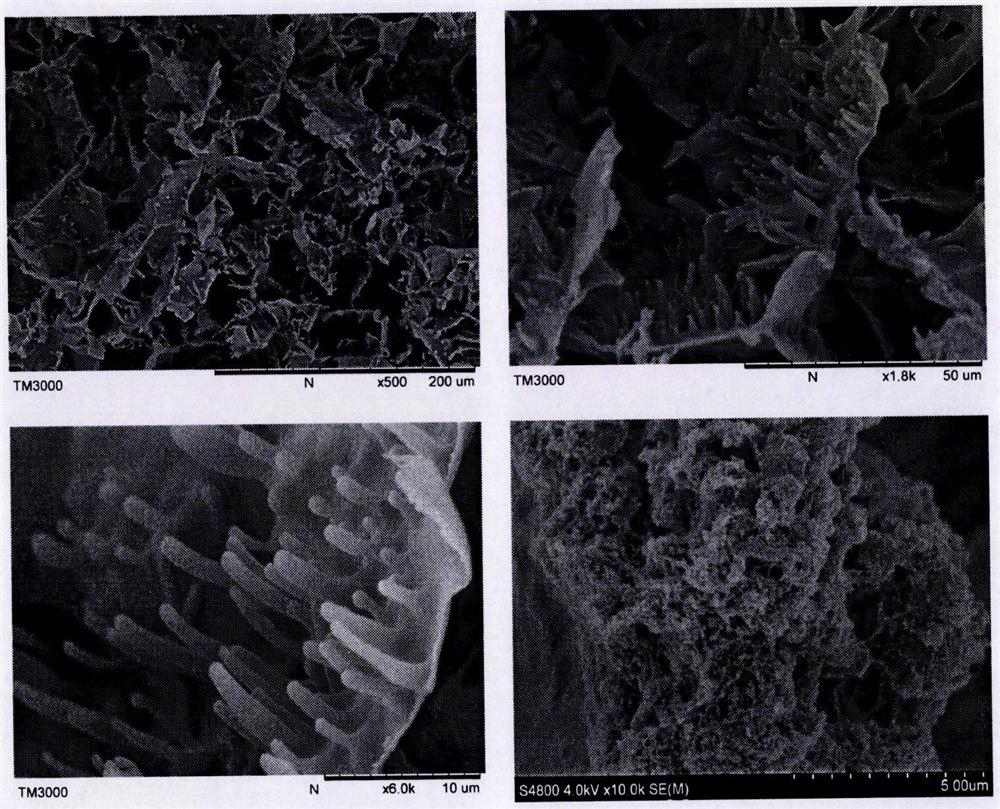

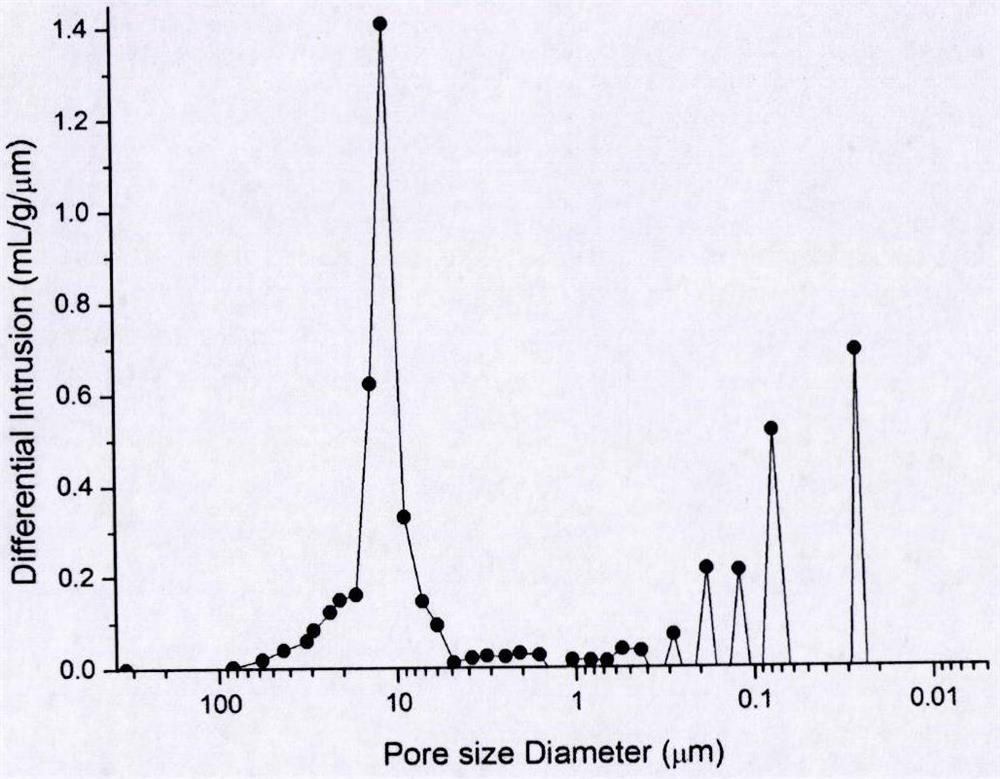

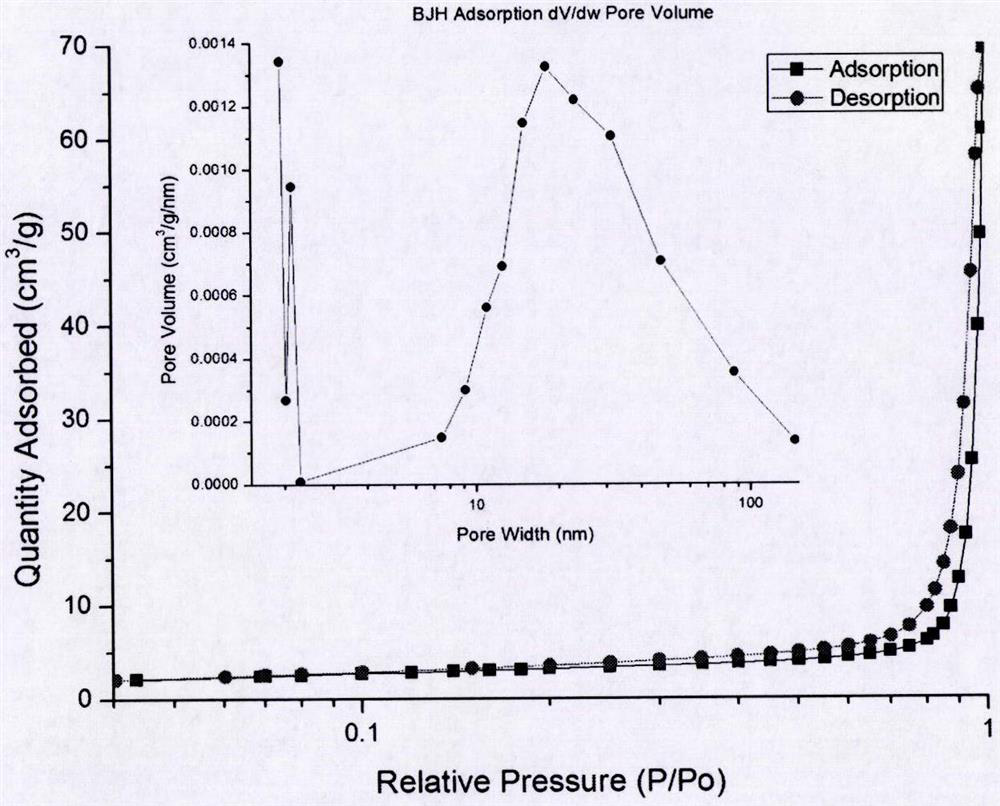

Image

Examples

Embodiment 1

[0021] 35.0g of trimethylolpropane is heated and completely melted to a transparent and flowing liquid, then add 3.5g of epoxy resin E-51 and stir vigorously to obtain a viscous liquid, then add 0.44g of diethylenetriamine, cool with ice water and stir vigorously Make it release heat evenly to obtain a viscous semi-solid containing a large number of tiny crystals, pour it into a plastic mold, and place it in the refrigerator for further cooling and crystallization for 3 hours after being completely solidified to obtain a hard white solid, which is solidified at 45°C for 12 hours, soaked in water repeatedly until the trimethylolpropane was completely removed, then dried in vacuum at room temperature to obtain a white foam material.

Embodiment 2

[0023] 60.0g of trimethylolpropane was heated and melted until it became a transparent and flowable liquid, and 3.0g of epoxy resin E-51 was added to stir and disperse, and 0.44g of diethylenetriamine was added, cooled with ice water and vigorously stirred to make the exotherm uniform, and viscous Thick semi-solid, which contains a large number of tiny crystals, poured into a plastic mold, after being completely solidified, placed in the refrigerator for further cooling and crystallization for 3 hours, after freezing, a hard white solid was obtained, solidified at 45°C for 12 hours, soaked in water repeatedly After the trimethylolpropane was completely removed, it was dried in vacuum at room temperature to obtain a white foamy material.

Embodiment 3

[0025] Heat and melt 90.0g trimethylolpropane until it becomes a transparent and flowing liquid, add 3.0g epoxy resin E-51 and stir to disperse, then add 0.50g diethylenetriamine, keep stirring to obtain a good dispersion, cool with ice water and vigorously Stir to make it release heat evenly to obtain a viscous semi-solid, which contains a large number of tiny crystals, pour it into a plastic mold, and place it in the refrigerator for further cooling and crystallization for 4 hours after being completely solidified. After freezing, a hard white solid is obtained. It was cured at ℃ for 14 hours, soaked in water repeatedly until the trimethylolpropane was completely removed, and then dried in vacuum at room temperature to obtain a white foam material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| macropore | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com