System and method for preparing oxygen by vacuum pressure swing adsorption

A technology of vacuum pressure swing adsorption and oxygen generation system, which is applied in separation methods, chemical instruments and methods, oxygen preparation, etc., can solve problems such as load adjustment, unfavorable optimization control, equipment impact, etc., to reduce noise and energy consumption, and effectively Facilitate adsorption operation and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

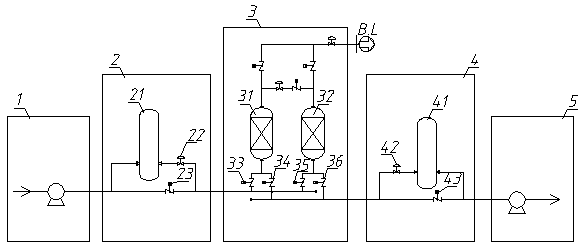

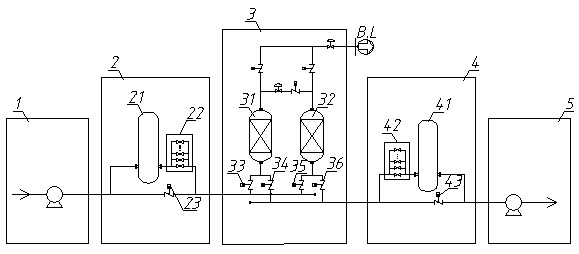

[0046] Such as figure 1 As shown, a vacuum pressure swing adsorption oxygen production system includes a rate fan 1, an adsorption separation unit 3 and a rate vacuum pump 5, and a fan worker is connected between the air inlet of the adsorption separation unit 3 and the rate fan 1 A condition control unit 2, a vacuum pump working condition control unit 4 is connected between the exhaust port of the adsorption separation unit 3 and the rate vacuum pump 5;

[0047] The fan operating condition control unit 2 includes a buffer tank A21, a control valve A22 and a valve A23. The buffer tank A21 is connected in series with the control valve A22 through a pipeline. The buffer tank A21 and the control valve A22 are connected in series and then connected in parallel with the valve A23. Both the control valve A22 and the valve A23 communicate with the air inlet of the adsorption separation unit 3;

[0048] The working condition control unit 4 of the vacuum pump includes a buffer tank B4...

Embodiment 2

[0053] Such as figure 1 As shown, a vacuum pressure swing adsorption oxygen production system includes a rate fan 1, an adsorption separation unit 3 and a rate vacuum pump 5, and a fan worker is connected between the air inlet of the adsorption separation unit 3 and the rate fan 1 A condition control unit 2, a vacuum pump working condition control unit 4 is connected between the exhaust port of the adsorption separation unit 3 and the rate vacuum pump 5;

[0054] The fan operating condition control unit 2 includes a buffer tank A21, a control valve A22 and a valve A23. The buffer tank A21 is connected in series with the control valve A22 through a pipeline. The buffer tank A21 and the control valve A22 are connected in series and then connected in parallel with the valve A23. Both the control valve A22 and the valve A23 communicate with the air inlet of the adsorption separation unit 3;

[0055] The working condition control unit 4 of the vacuum pump includes a buffer tank B4...

Embodiment 3

[0062] Such as figure 1 As shown, a vacuum pressure swing adsorption oxygen production system includes a rate fan 1, an adsorption separation unit 3 and a rate vacuum pump 5, and a fan worker is connected between the air inlet of the adsorption separation unit 3 and the rate fan 1 A condition control unit 2, a vacuum pump working condition control unit 4 is connected between the exhaust port of the adsorption separation unit 3 and the rate vacuum pump 5;

[0063] The fan operating condition control unit 2 includes a buffer tank A21, a control valve A22 and a valve A23. The buffer tank A21 is connected in series with the control valve A22 through a pipeline. The buffer tank A21 and the control valve A22 are connected in series and then connected in parallel with the valve A23. Both the control valve A22 and the valve A23 communicate with the air inlet of the adsorption separation unit 3;

[0064] The working condition control unit 4 of the vacuum pump includes a buffer tank B4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com