Metal powder dehydration device

A dehydration device and metal powder technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor product quality, poor dehydration quality, and low dehydration efficiency, and achieve simple structure, improved processing quality, and improved Effect of dehydration efficiency and dehydration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

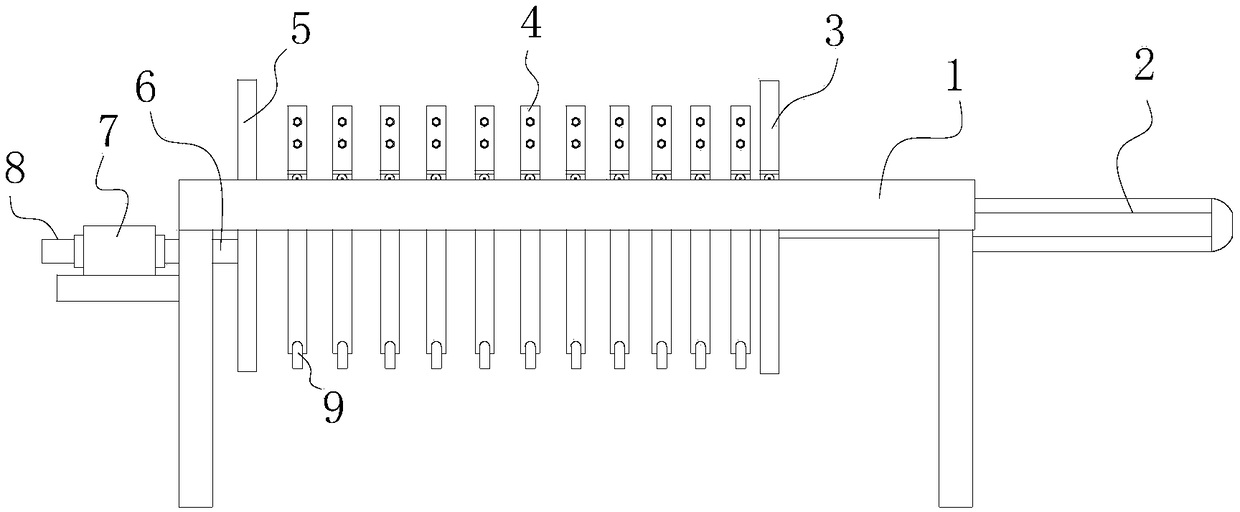

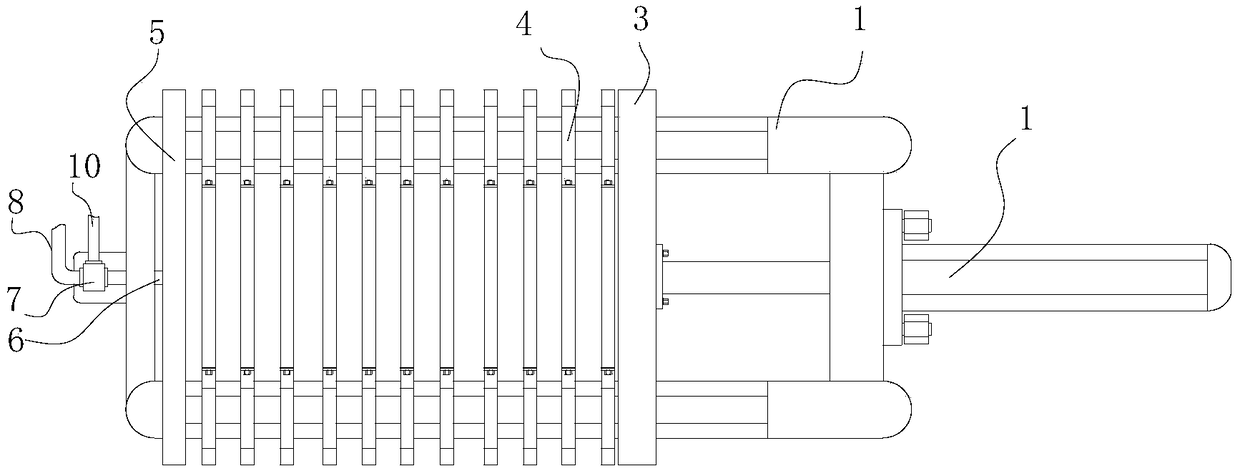

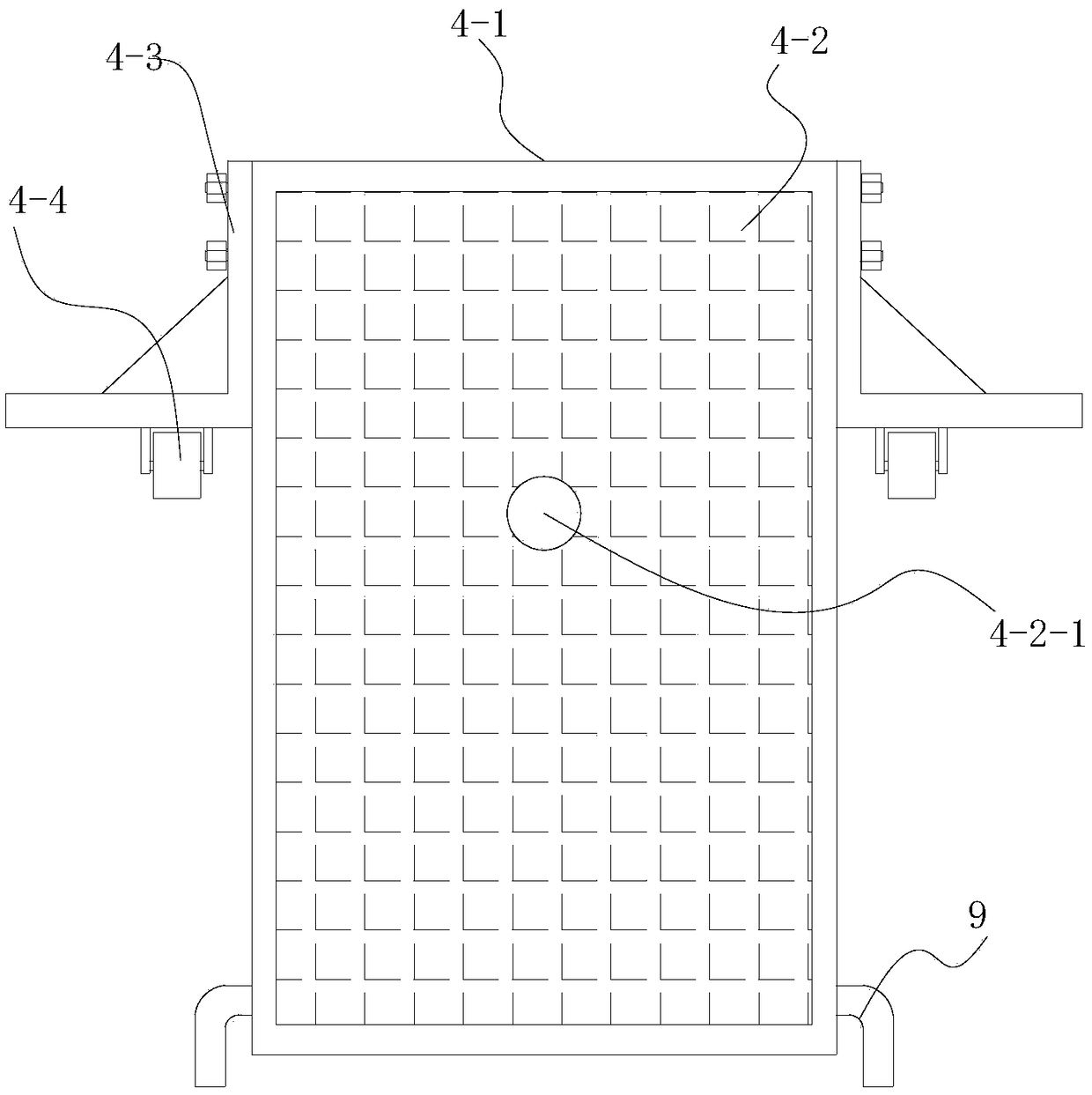

[0021] Such as Figure 1 to Figure 3 As shown, a metal powder dehydration device includes a lifting mechanism and a dehydration device arranged on the lifting mechanism. The lifting mechanism is composed of a support frame and two parallel guide rails 1 arranged on the support frame. The dehydration device is composed of a feeding mechanism, a loading mechanism and its linear drive assembly 2. The left end of the guide rail 1 is provided with a vertical constant pressure plate 5, and the positioning plate 5 can be welded on the guide rail 1. The right end of the guide rail 1 A vertical dynamic pressure plate 3 is provided, and the dynamic pressure plate 3 and the fixed pressure plate 5 are distributed parallel. The end part communicates with the discharge port of the ball mill at the far end, and a pressure pump is provided on the feeding pipe 8, the end of the booster air pipe 10 communicates with the external booster air pump, and the three-way valve 7 is installed on the le...

Embodiment 2

[0023] Such as Figure 1 to Figure 4 As shown, a metal powder dehydration device includes a lifting mechanism and a dehydration device arranged on the lifting mechanism. The lifting mechanism is composed of a support frame and two parallel guide rails 1 arranged on the support frame. The dehydration device is composed of a feeding mechanism, a loading mechanism and its linear drive assembly 2. The left end of the guide rail 1 is provided with a vertical constant pressure plate 5, and the positioning plate 5 can be welded on the guide rail 1. The right end of the guide rail 1 A vertical dynamic pressure plate 3 is provided, and the dynamic pressure plate 3 and the fixed pressure plate 5 are distributed parallel. The end part communicates with the discharge port of the ball mill at the far end, and a pressure pump is provided on the feeding pipe 8, the end of the booster air pipe 10 communicates with the external booster air pump, and the three-way valve 7 is installed on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com