Peanut brushing device capable of reducing shell-breaking rate

A peanut and anti-break technology, applied in the application, food processing, food science and other directions, can solve the problems of high shell breaking and shell breaking rate, and achieve the effect of reducing the shell breaking rate, low shell breaking rate, and improving the brushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

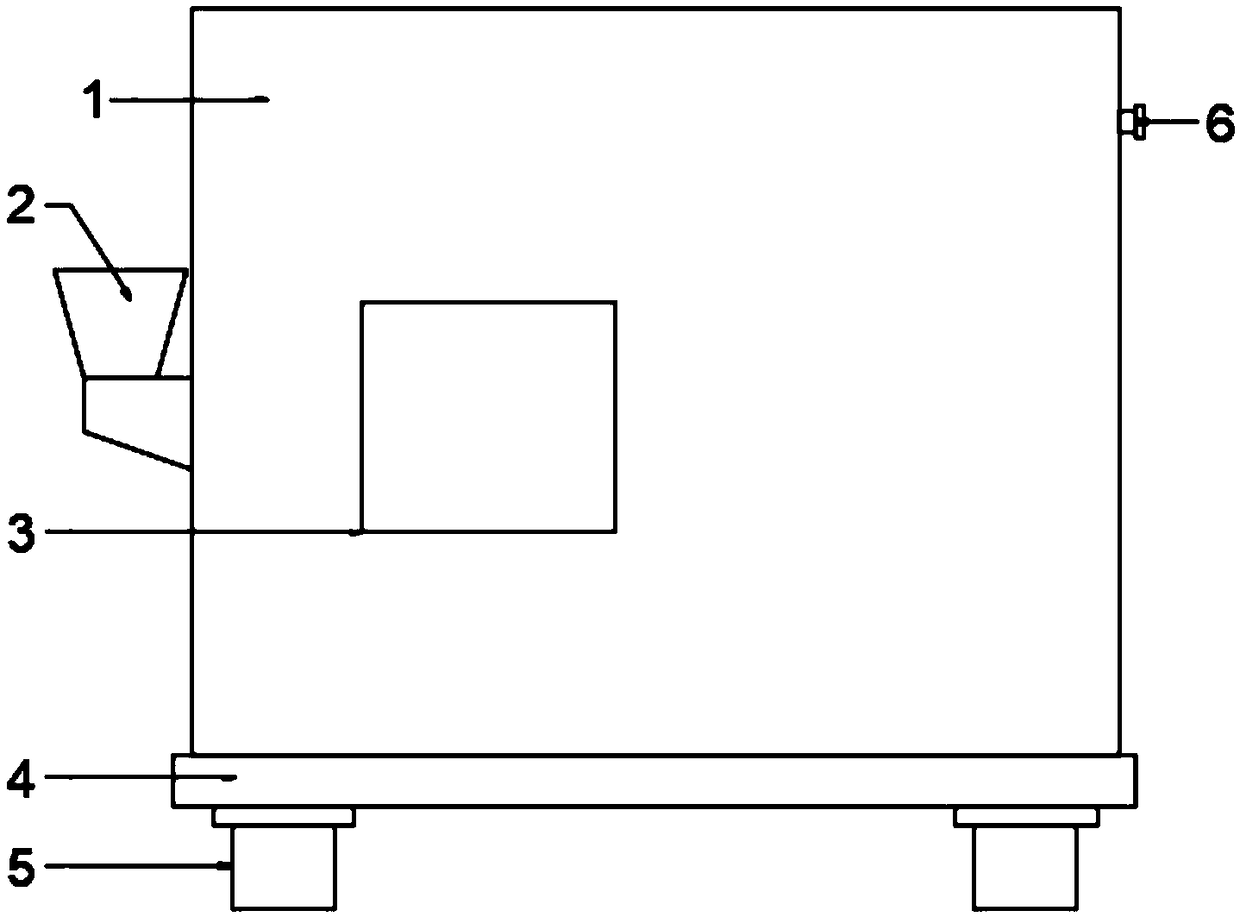

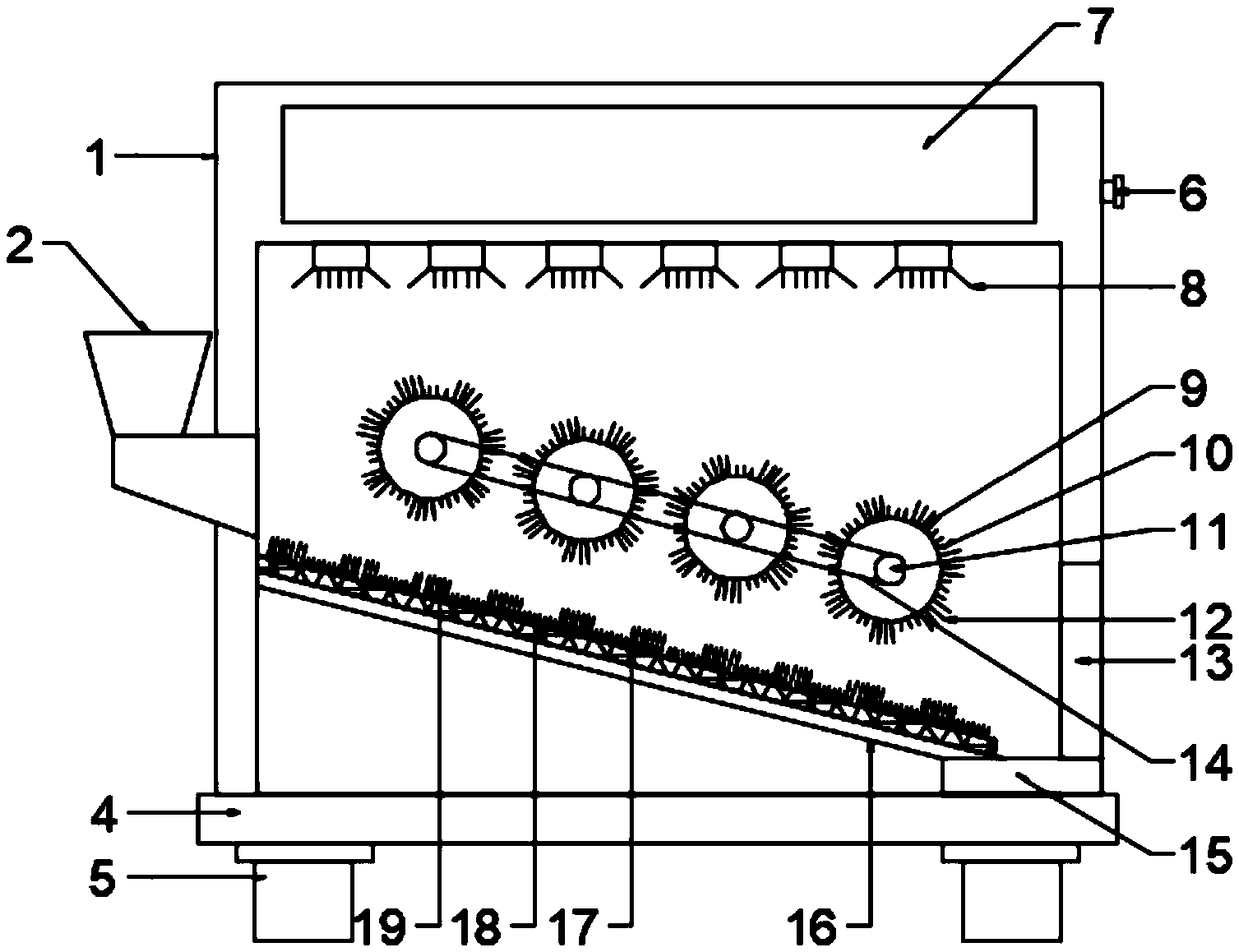

[0026] see figure 1 and figure 2 , a peanut brushing device that can reduce the rate of preventing shell breakage, including a brush roller group 9 and a connecting plate 17, the brush roller group 9 is rotatably mounted on the housing 1, and the brush roller group 9 is provided with equally spaced brush rollers. The roller is provided with a first short bristle group 10 and a first long bristle group 12 distributed in a cross array, the upper casing 1 of the brush roller group 9 is provided with a spray disc 8 distributed in an array, and the upper surface of the connecting plate 17 is provided with a cross. The second short bristle group 18 and the second long bristle group 19 distributed in the array, the length of the short bristles on the first short bristle group 10 and the second short bristle group 18 is 5cm, the first long bristle group 12 and the second long bristles The length of the long bristles on the group 19 is 8cm, and the first short bristle group 10 and th...

Embodiment 2

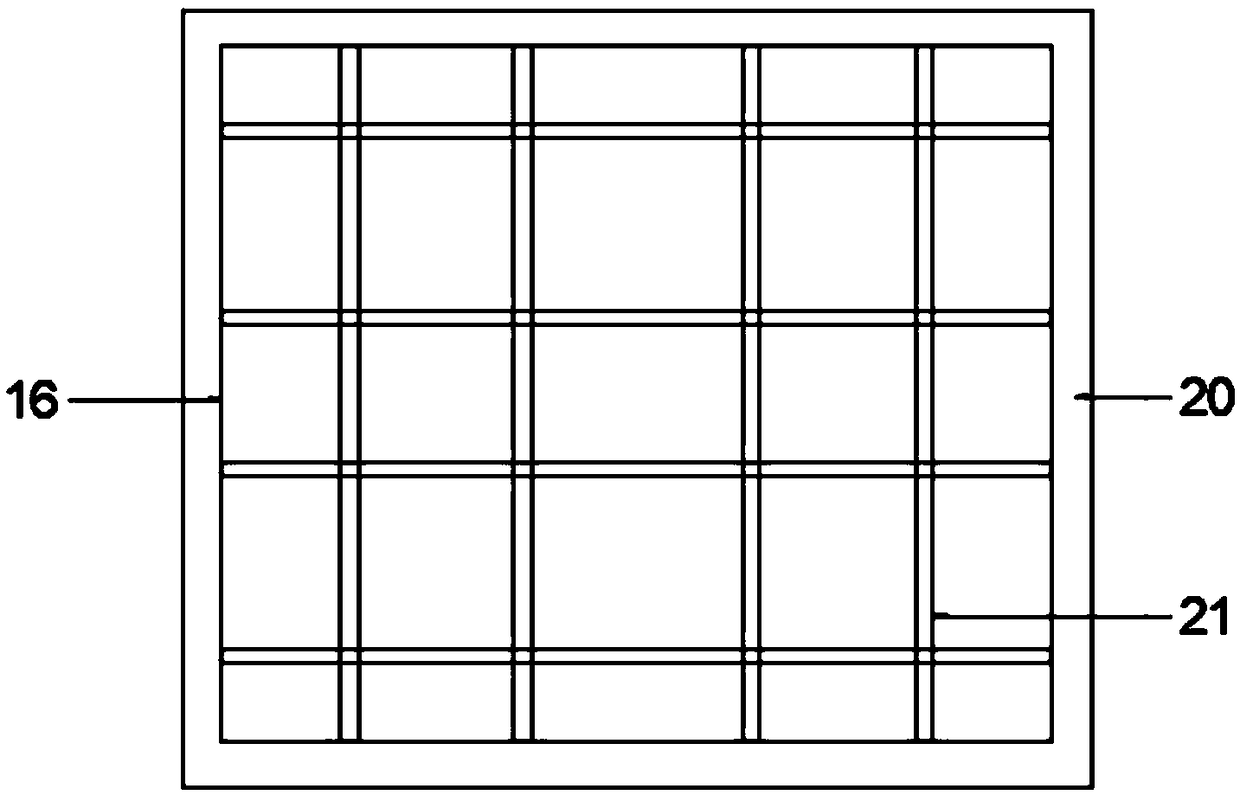

[0029] see Figure 1-2 , 4, a peanut brushing device that can reduce the anti-shell rate, including a brush roller group 9 and a connecting plate 17, the brush roller group 9 is rotatably mounted on the housing 1, and the brush roller group 9 is provided with brush rollers distributed at equal intervals , the brush roller is provided with a first short bristle group 10 and a first long bristle group 12 distributed in a cross-array, the upper casing 1 of the brush roller group 9 is provided with an array of spray discs 8, and the upper surface of the connecting plate 17 is provided with There are a second short bristle group 18 and a second long bristle group 19 distributed in a cross array, the length of the short bristles on the first short bristle group 10 and the second short bristle group 18 is 5cm, and the first long bristle group 12 and the second The length of the long bristles on the long bristle group 19 is 8cm, and the first short bristle group 10 and the first long ...

Embodiment 3

[0032] see Figure 1-3 , a peanut brushing device that can reduce the rate of preventing shell breakage, including a brush roller group 9 and a connecting plate 17, the brush roller group 9 is rotatably mounted on the housing 1, and the brush roller group 9 is provided with equally spaced brush rollers. The roller is provided with a first short bristle group 10 and a first long bristle group 12 distributed in a cross array, the upper casing 1 of the brush roller group 9 is provided with a spray disc 8 distributed in an array, and the upper surface of the connecting plate 17 is provided with a cross. The second short bristle group 18 and the second long bristle group 19 distributed in the array, the length of the short bristles on the first short bristle group 10 and the second short bristle group 18 is 5cm, the first long bristle group 12 and the second long bristles The length of the long bristles on the group 19 is 8cm, and the first short bristle group 10 and the first long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com